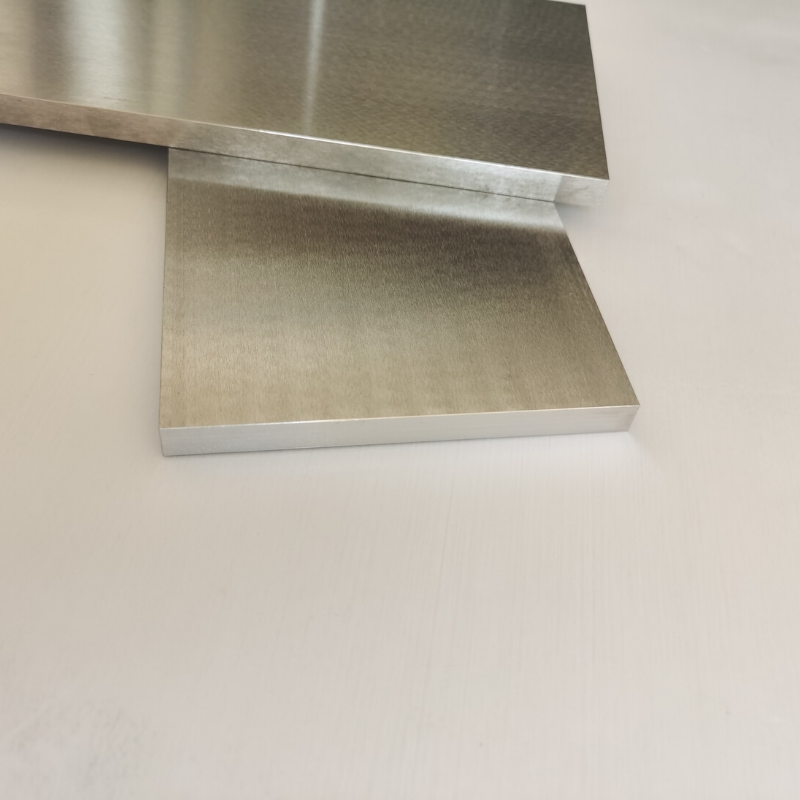

CuP Sputtering Target High Purity Thin Film Pvd Coating Custom Made

Copper Phosphorus

Copper Phosphorus alloys are generally utilized for deoxidizing copper and copper alloys. Even though there are many other deoxidants available, phosphorus has demonstrated to be the most economical.

Copper Phosphorus alloys also serve as an alloying agent into order to add a certain amount of phosphorus in copper alloys, including phosphor bronze and many different brazing alloys. The addition of phosphorus increases the fluidity of the metal.

CuP8 master alloy is used in the aluminum industry to treat hypereutectic Aluminum Silicon foundry alloys for controlling the morphology and size of the solidifying primary silicon phase in order to increase the machinability, wear resistance and toughness of the alloy. When Copper Phosphorus alloys are employed for deoxidation applications, obtaining a residual phosphorus level of 0.010% to 0.015% is a common practice for preventing reoxidation, especially during the casting process.

Copper Phosphorus alloys serve as an efficient deoxidant for Copper-Lead-Tin, Copper-Tin-Zinc, and Copper-Tin casting alloys. Nevertheless, they cannot be used for deoxidizing high conductivity copper because phosphorus is detrimental to electrical conductivity.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Copper Phosphorus Sputtering Materials according to Customers’ specifications. For more information, please contact us.