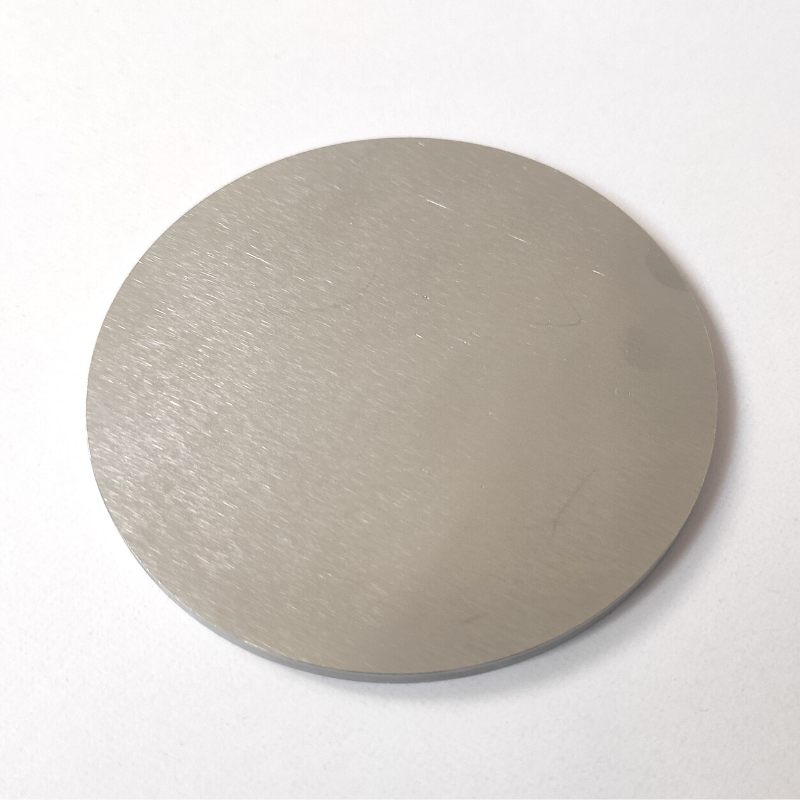

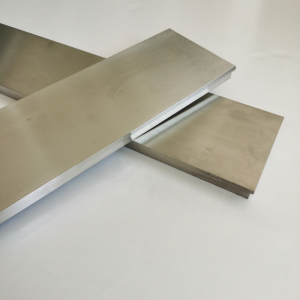

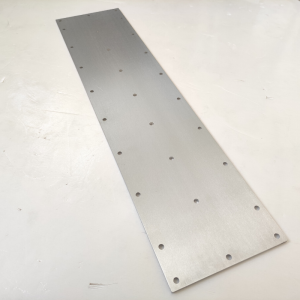

AlZn Sputtering Target High Purity Thin Film PVD Coating Custom Made

Aluminum zinc

Pure forms of zinc are often used to die cast large quantities of small parts because of its high specific gravity, but it’s not preferred for many other types of applications because it is considered a weak metal that has up to 50 percent less tensile strength than steel. In order to reduce the negative properties of zinc, like it’s low tensile strength and brittleness, it is often combined with a certain percentage of aluminum. AlZn alloy exhibits good strength, hardness, bearing, mechanical damping properties and molding performance and is widely used in a variety of industries, including bearing, die casting, oil & gas, aerospace and turbine.

An Aluminum-doped zinc oxide (AZO) thin film could be formed during the deposition process of Aluminum Zinc sputtering target. It is used in Low-E glass, touch panel, LCD industries. Aluminum Zinc target has one great advantage compared to ceramic sputtering target for its availability for large size.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Aluminum Zinc Sputtering Materials according to Customers’ specifications. Our products feature excellent mechanical properties, homogeneous structure, polished surface with no segregation, pores or cracks. For more information, please contact us.