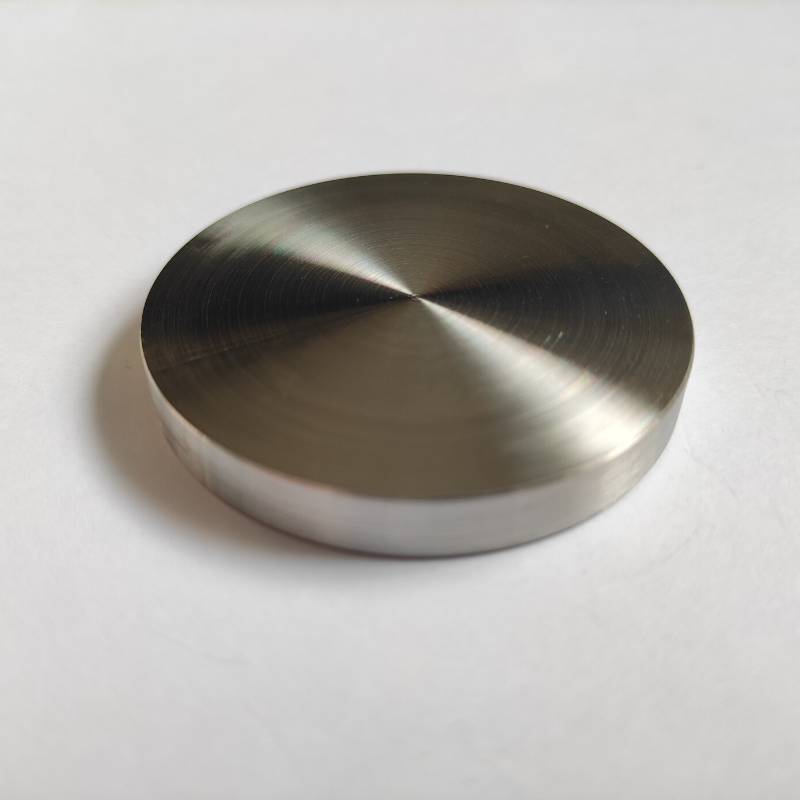

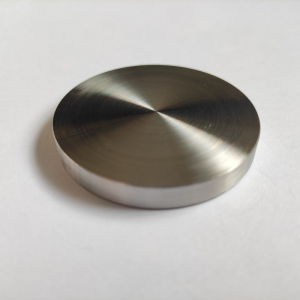

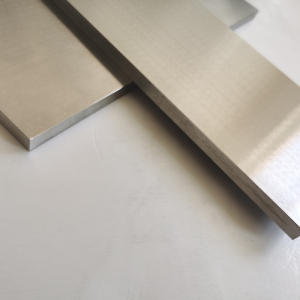

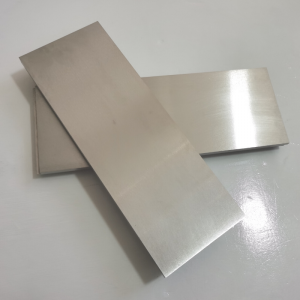

WMo Sputtering Target High Purity Thin Film Pvd Coating Custom Made

Tungsten Molybdenum Alloy Sputtering Target

Tungsten Molybdenum Sputtering Target Description

Tungsten molybdenum sputtering target is a type of alloy sputtering target composed of molybdenum and tungsten.

Molybdenum is a chemical element originated from the Greek ‘molybdos’ meaning lead. It was first mentioned in 1778 and observed by W. Scheele. The isolation was later accomplished and announced by J. Hjelm. “Mo” is the canonical chemical symbol of molybdenum. Its atomic number in the periodic table of elements is 42 with location at Period 5 and Group 6, belonging to the d-block. The relative atomic mass of molybdenum is 95.94(2) Dalton, the number in the brackets indicating the uncertainty.

Tungsten, also called wolfram; wolframium, is a chemical element originated from the Swedish ‘tung sten’ meaning heavy stone(W is wolfram, the old name of the tungsten mineral wolframite). It was first mentioned in 1781 and observed by T. Bergman. The isolation was later accomplished and announced by J. and F. Elhuyar. “W” is the canonical chemical symbol of tungsten. Its atomic number in the periodic table of elements is 74 with location at Period 6 and Group 6, belonging to the d-block. The relative atomic mass of tungsten is 183.84(1) Dalton, the number in the brackets indicating the uncertainty.

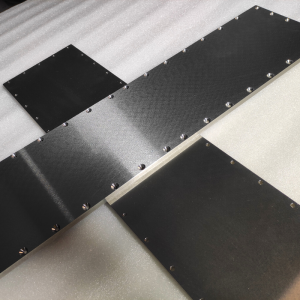

Tungsten Molybdenum Target Packaging

Our Tungsten molybdenum sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Get Contact

RSM’s tungsten molybdenum sputtering targets are of ultra-high purity and uniform. They are available in various forms, purities, sizes, and prices. We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.