Well-designed Titanium Nitride Tin Sputtering Targets - Niv Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich

Well-designed Titanium Nitride Tin Sputtering Targets - Niv Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich Detail:

Nickel Vanadium Sputtering Target Description

Gold is often applicated in the deposition of integrated circuit layer, but AuSi low-melting compound is often formed if Gold is combined with Silicon, which would cause the looseness between different layers. Pure Nickel is a good choice for Adhesive layer, while a Barrier layer is also required between the Nickel and Gold layer to prevent proliferation. Vanadium could perfectly satisfy this requirement with high melting point and capacity of standing high ampere density. Therefore Nickel, Vanadium and Gold are three materials usually applicated in integrated circuit industry. Nickel Vanadium Sputtering Target is manufactured by adding Vanadium into molten Nickel. With low ferromagnetism, it is a good choice for the magnetron sputtering of electronic products, which could produce Nickel layer and Vanadium layer in one time.

Ni-7V wt% Impurity Content

|

Purity |

Main Component(wt%) |

Impurity Chemicals(≤ppm) |

Impurity In total(≤ppm) |

||||||

|

V |

Fe |

Al |

Si |

C |

N |

O |

S |

||

|

99.99 |

7±0.5 |

20 |

30 |

20 |

100 |

30 |

100 |

20 |

100 |

|

99.95 |

7±0.5 |

200 |

200 |

200 |

100 |

100 |

200 |

50 |

500 |

|

99.9 |

7±0.5 |

300 |

300 |

300 |

100 |

100 |

200 |

50 |

500 |

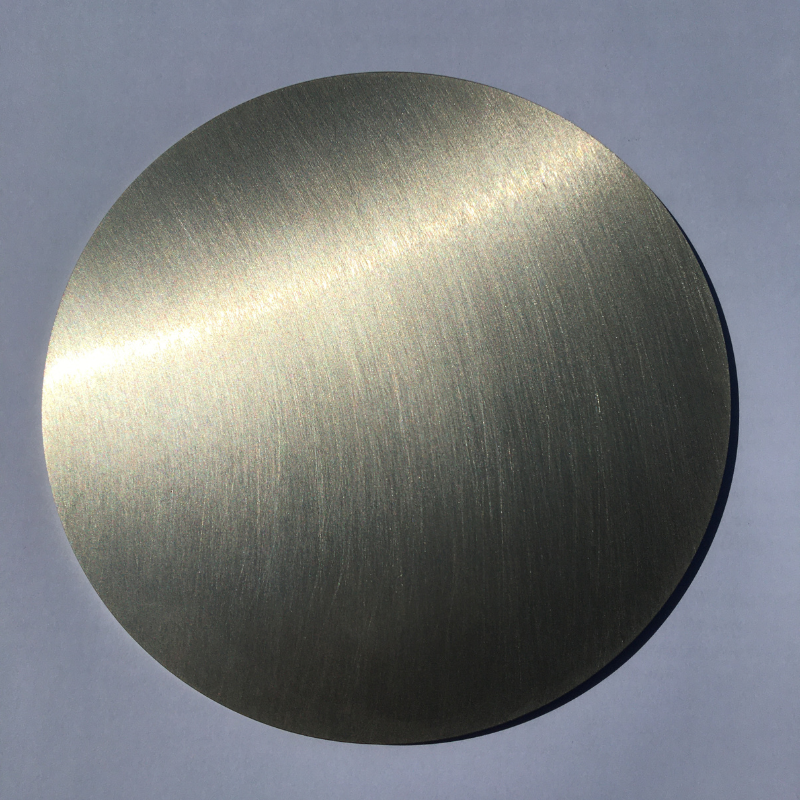

Nickel Vanadium Sputtering Target Packaging

Our Nickel Vanadium sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Get Contact

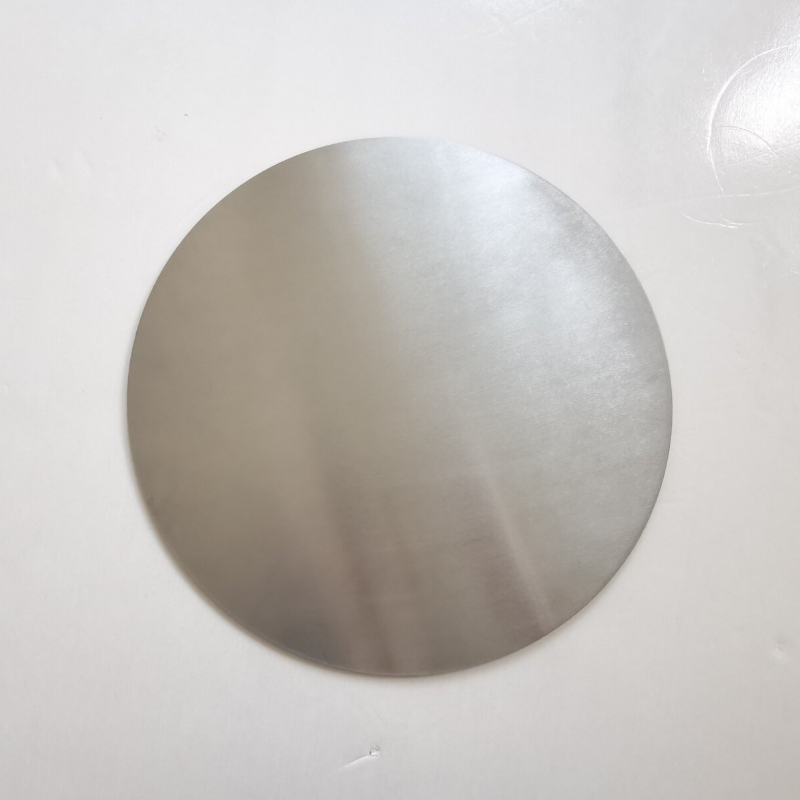

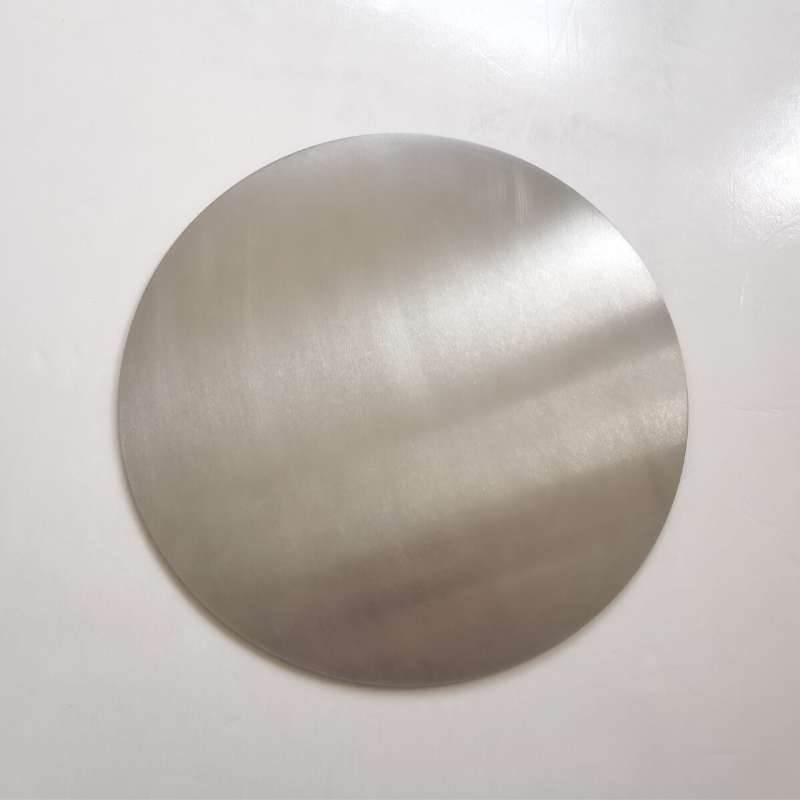

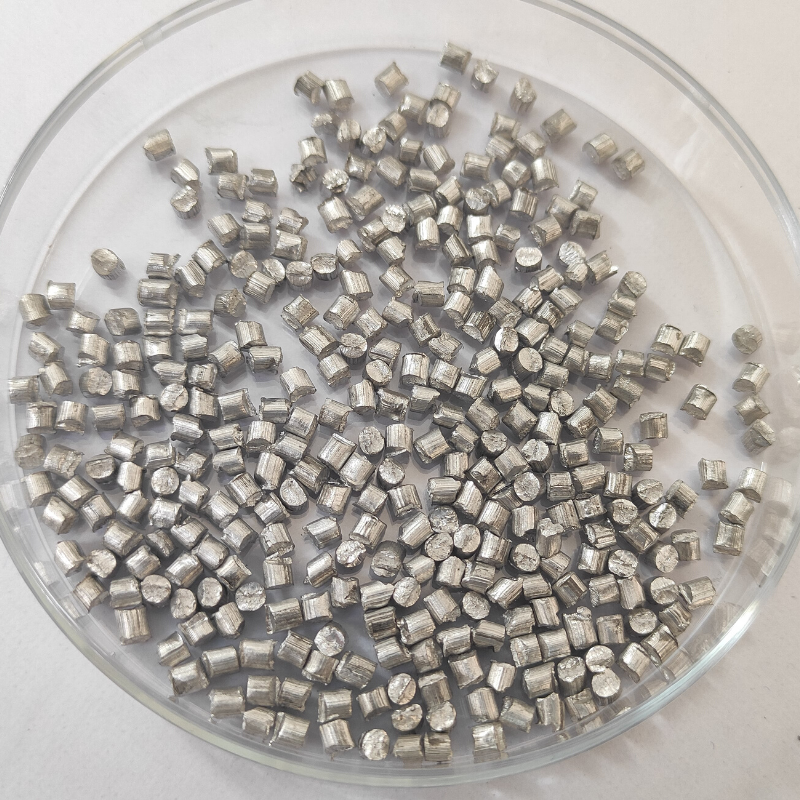

RSM’s Nickel Vanadium sputtering targets are of ultra-high purity and uniform. They are available in various forms, purities, sizes, and prices. We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.

Product detail pictures:

Related Product Guide:

owing to very good support, a variety of high quality merchandise, aggressive costs and efficient delivery, we love an excellent name among the our clients. We are an energetic company with wide market for Well-designed Titanium Nitride Tin Sputtering Targets - Niv Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich , The product will supply to all over the world, such as: Porto, Durban, Serbia, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to provide our clients sincerely with qualified products, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.