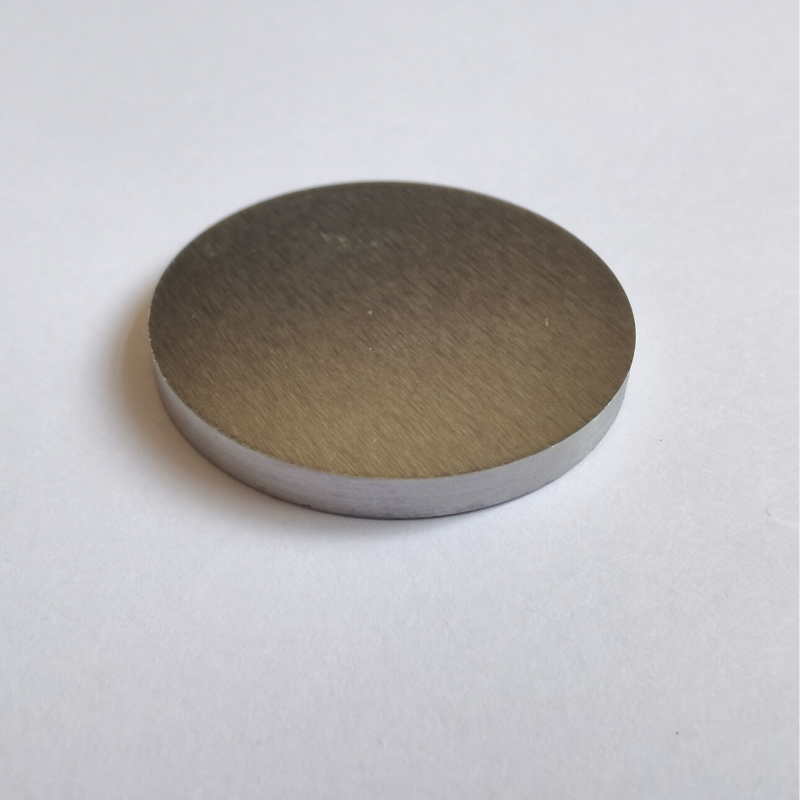

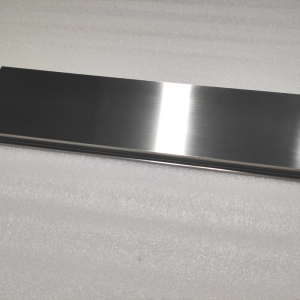

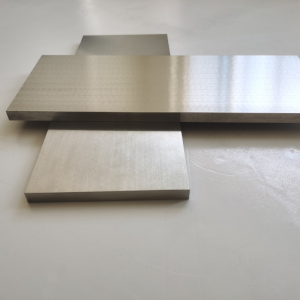

NiCu Sputtering Target High Purity Thin Film Pvd Coating Custom Made

Nickel Copper

Nickel Copper Sputtering Target Description

Copper and nickel are adjacent to one another in the periodic system of elements, with atomic numbers 29 and 28 and atomic weights 63.54 and 68.71. These two elements are closely related and are completely miscible in both the liquid and solid state.

Nickel has a marked effect on the color of Cu-Ni alloys. The copper color becomes lighter as nickel is added. Alloys are almost silvery white from about 15% nickel. The lustre and purity of the color increases with nickel content; from about 40% nickel, a polished surface can hardly be distinguished from that of silver. Ni-Cu alloy has good electrical and mechanical properties, and extensively used in display and electrical resistance industries.

Nickel Copper Sputtering Target Packaging

Our Nickel Copper sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Get Contact

RSM's Nickel Copper sputtering targets are of ultra-high purity and uniform. They are available in various forms, purities, sizes, and prices. Our typical ratios: Ni-20Cu wt%,Ni-30Cu wt%,Ni-56Cu wt%,Ni-70Cu wt%,Ni-80Cu wt%.

We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.