Manufacturing Companies for High-Entropy Alloy - Factory Price chromium aluminum molybdenum sputtering target Cr25-Al70-Mo5 high purity 99.7% metal alloy target – Rich

Manufacturing Companies for High-Entropy Alloy - Factory Price chromium aluminum molybdenum sputtering target Cr25-Al70-Mo5 high purity 99.7% metal alloy target – Rich Detail:

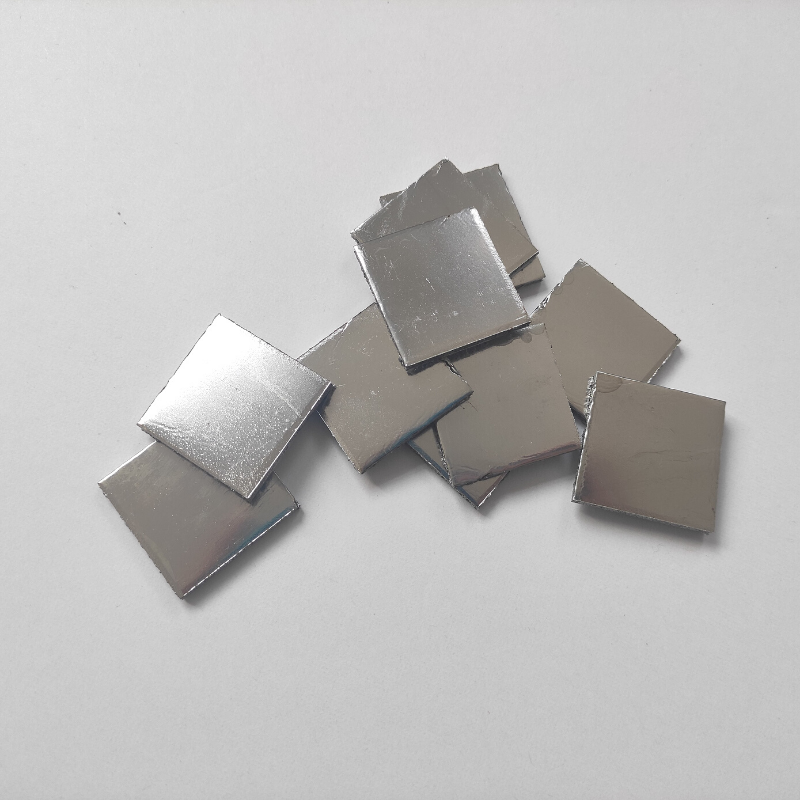

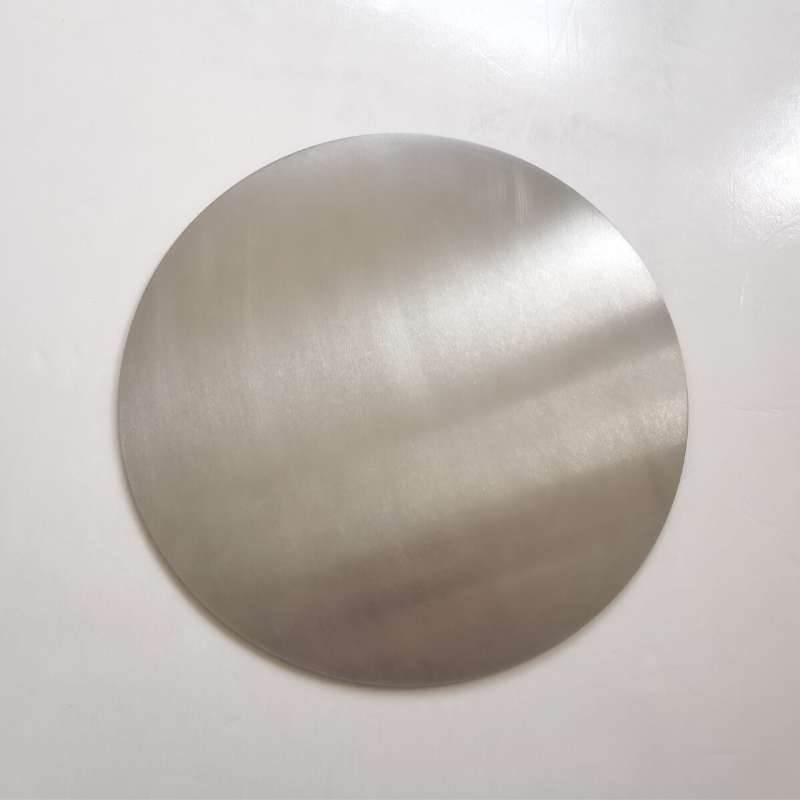

Factory Price chromium aluminum molybdenum sputtering target Cr25-Al70-Mo5 high purity 99.7% metal alloy target,

sputtering target chromium Aluminium Molybdenum sputtering target metal alloy targets,

Chromium cobalt sputtering target from Rich Special Materials is a silvery alloy sputtering material containing Cr and Co.

Chromium is a chemical element that originated from the Greek ‘chroma’, meaning color. It was early used before 1 AD and discovered by Terracotta Army. “Cr” is the canonical chemical symbol of chromium. Its atomic number in the periodic table of elements is 24 with a location at Period 4 and Group 6, belonging to the d-block. The relative atomic mass of chromium is 51.9961(6) Dalton, the number in the brackets indicating the uncertainty.

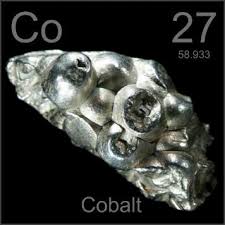

Cobalt is a chemical element that originated from the German word ‘kobald’, meaning goblin. It was first mentioned in 1732 and observed by G. Brandt. “Co” is the canonical chemical symbol of cobalt. Its atomic number in the periodic table of elements is 27 with a location at Period 4 and Group 9, belonging to the d-block. The relative atomic mass of cobalt is 58.933195(5) Dalton, the number in the brackets indicating the uncertainty.

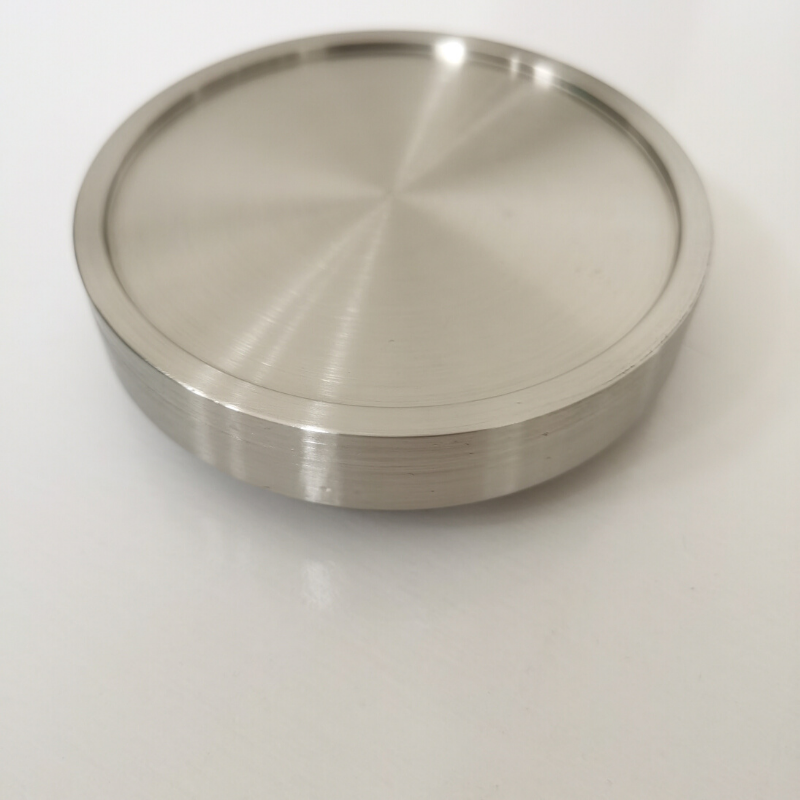

Chronium Cobalt Sputtering Targets are manufactured by means of Vacuum Melting and PM. CrCo has superior specific strength and has been used in various fields where high wear-resistance was needed including aerospace industry, cutlery, bearings, blades, etc.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Chronium Cobalt Sputtering Materials according to Customers’ specifications. For more information, please contact us.Chrome-molybdenum aluminum alloy is a target material made of high-purity raw materials, carefully mixed powder, isostatic pressing, with high purity and high density. The deposited coating is delicate, good adhesion, high hardness, good wear resistance, high temperature oxidation resistance, and is an ideal mold coating material.

Chrome aluminum-molybdenum alloy has high nitriding properties and mechanical properties, good heat resistance and corrosion resistance, after nitriding treatment, can get high surface hardness, high fatigue strength and good resistance to overheating, no tempering brittleness, cutting processability is acceptable, high temperature working temperature up to 500 °C, but low plasticity when cold deformation, poor weldability, low hardenability, generally used after quenching and tempering and nitriding.

Product detail pictures:

Related Product Guide:

continue to enhance, to be certain solution top quality in line with market and buyer standard requirements. Our corporation has a excellent assurance program are actually established for Manufacturing Companies for High-Entropy Alloy - Factory Price chromium aluminum molybdenum sputtering target Cr25-Al70-Mo5 high purity 99.7% metal alloy target – Rich , The product will supply to all over the world, such as: Oman, Malaysia, Portugal, To win customers' confidence, Best Source has set up a strong sales and after-sales team to provide the best product and service. Best Source abides by the idea of "Grow with customer" and philosophy of "Customer-oriented" to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let's grow together!

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.