Low MOQ for Silicon Si Sputtering Target - CoCrAlY Alloy Sputtering Target High Purity Thin Film PVD Coating Custom Made – Rich

Low MOQ for Silicon Si Sputtering Target - CoCrAlY Alloy Sputtering Target High Purity Thin Film PVD Coating Custom Made – Rich Detail:

Cobalt Chromium Aluminum Yttrium Sputtering Target Description

Cobalt Chromium Aluminum Yttrium sputtering target is a Cobalt-based alloy with addition of Chromium Aluminum and Yttrium elements. It exhibits great corrosion resistant behavior in fused salt medium (sodium sulfate, sodium nitrate, sodium carbonate, calcium sulfate, calcium sulfate, sodium chloride potassium chloride, sodium chloride sodium sulfate) at elevated temperatures. Chromium Aluminum Yttrium could have different ratios, depending on the operational environment of the layers. Usually, the alloy would display biphasic structure while the content of Chromium is 20-40%(wt, Aluminum 5-20%(wt), and Yttrium 0.5%(wt).

Cobalt Chromium Aluminum Yttrium targets could be deposited on the surface of high temperature components used in aerospace, aircraft, and gas turbine industries. This kind of layer could prolong the service life by ten thousand hours.

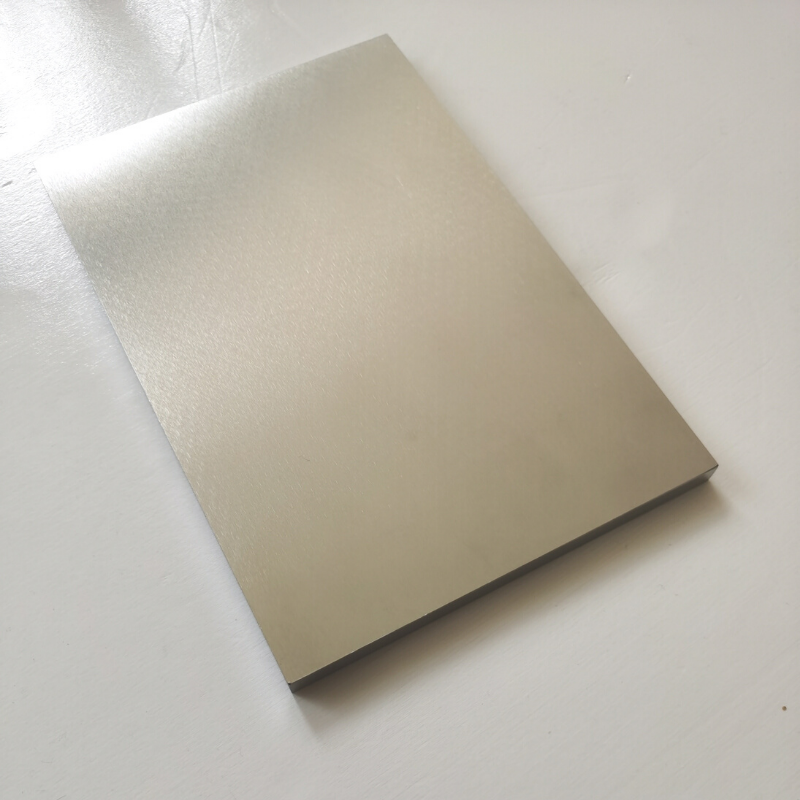

Cobalt Chromium Aluminum Yttrium Sputtering Target Packaging

Our CoCrAlY sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Get Contact

RSM’s Cobalt Chromium Aluminum Yttrium sputtering targets are of ultra-high purity and uniform. They are available in various forms, purities, sizes, and prices. We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our organization has strived to establish a highly efficient and stable employees team and explored an effective high-quality command method for Low MOQ for Silicon Si Sputtering Target - CoCrAlY Alloy Sputtering Target High Purity Thin Film PVD Coating Custom Made – Rich , The product will supply to all over the world, such as: Buenos Aires, Paraguay, Bhutan, With excellent products, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We will satisfy you with our professional service!

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.