Good User Reputation for Rh Sputtering Target - Vacuum Coating Material CoFeTaZr target Cobalt-Iron-Tantalum-Zirconium alloy target Magnetron Sputtering target – Rich

Good User Reputation for Rh Sputtering Target - Vacuum Coating Material CoFeTaZr target Cobalt-Iron-Tantalum-Zirconium alloy target Magnetron Sputtering target – Rich Detail:

Vacuum Coating Material CoFeTaZr target Cobalt-Iron-Tantalum-Zirconium alloy target Magnetron Sputtering target,

CoFeTaZr target,

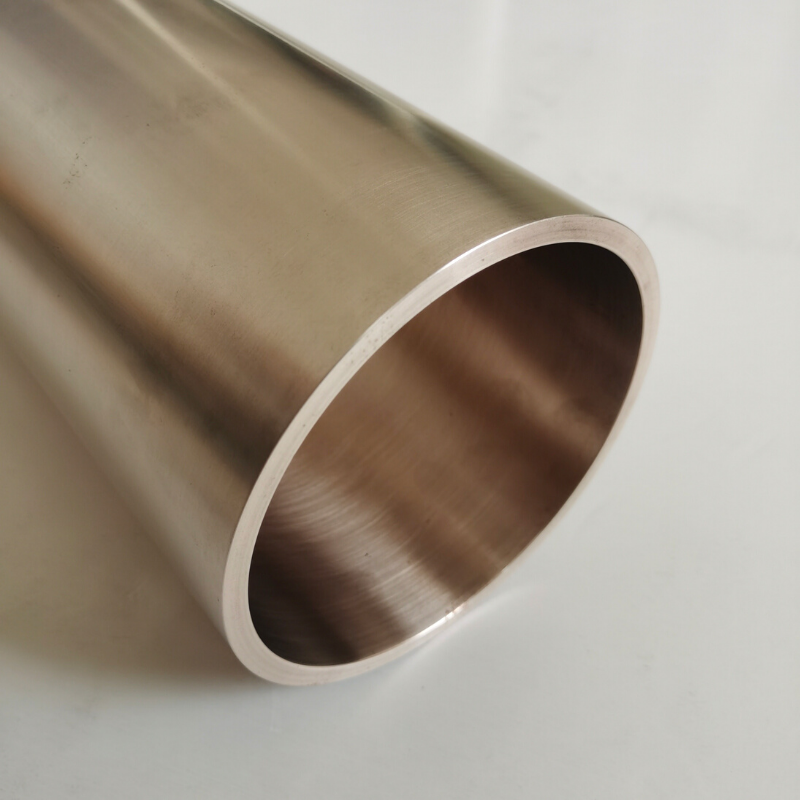

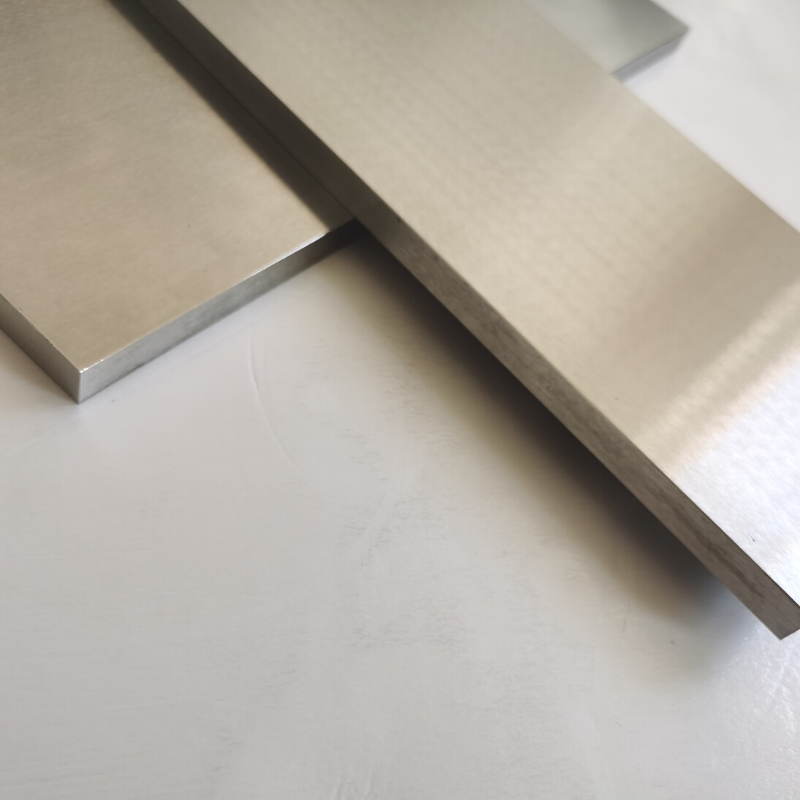

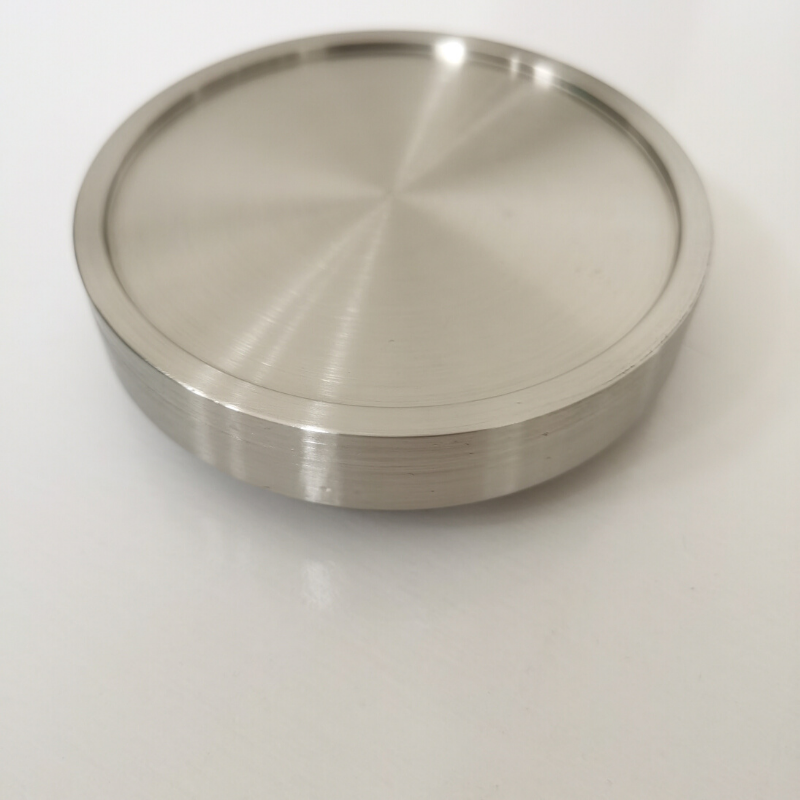

Chromium cobalt sputtering target from Rich Special Materials is a silvery alloy sputtering material containing Cr and Co.

Chromium is a chemical element that originated from the Greek ‘chroma’, meaning color. It was early used before 1 AD and discovered by Terracotta Army. “Cr” is the canonical chemical symbol of chromium. Its atomic number in the periodic table of elements is 24 with a location at Period 4 and Group 6, belonging to the d-block. The relative atomic mass of chromium is 51.9961(6) Dalton, the number in the brackets indicating the uncertainty.

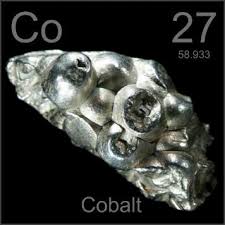

Cobalt is a chemical element that originated from the German word ‘kobald’, meaning goblin. It was first mentioned in 1732 and observed by G. Brandt. “Co” is the canonical chemical symbol of cobalt. Its atomic number in the periodic table of elements is 27 with a location at Period 4 and Group 9, belonging to the d-block. The relative atomic mass of cobalt is 58.933195(5) Dalton, the number in the brackets indicating the uncertainty.

Chronium Cobalt Sputtering Targets are manufactured by means of Vacuum Melting and PM. CrCo has superior specific strength and has been used in various fields where high wear-resistance was needed including aerospace industry, cutlery, bearings, blades, etc.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Chronium Cobalt Sputtering Materials according to Customers’ specifications. For more information, please contact us.Zirconium iron cobalt tantalum target material is made of high purity cobalt, iron, tantalum, zirconium by high vacuum melting of target material, the technology can effectively control the oxygen content of the target product and the use of special cooling of the mold, is alloy liquid rapid cooling, the alloy target material uniform structure, uniform composition distribution, small, through high temperature and high pressure densification processing, make the material is very dense, This provides a guarantee for the sputtering of high quality films. After heat treatment, the magnetic head ratio (PTF) of the target is significantly increased, and the thin films deposited by the cobalt-iron-tantalum-zirconium target are important soft magnetic layers in the vertical magnetic recording film.

Product detail pictures:

Related Product Guide:

Using a complete scientific top quality management program, great high-quality and fantastic religion, we win great track record and occupied this area for Good User Reputation for Rh Sputtering Target - Vacuum Coating Material CoFeTaZr target Cobalt-Iron-Tantalum-Zirconium alloy target Magnetron Sputtering target – Rich , The product will supply to all over the world, such as: Malta, Naples, South Africa, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!