Factory wholesale Aluminum Sputtering Target - Tialv Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich

Factory wholesale Aluminum Sputtering Target - Tialv Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich Detail:

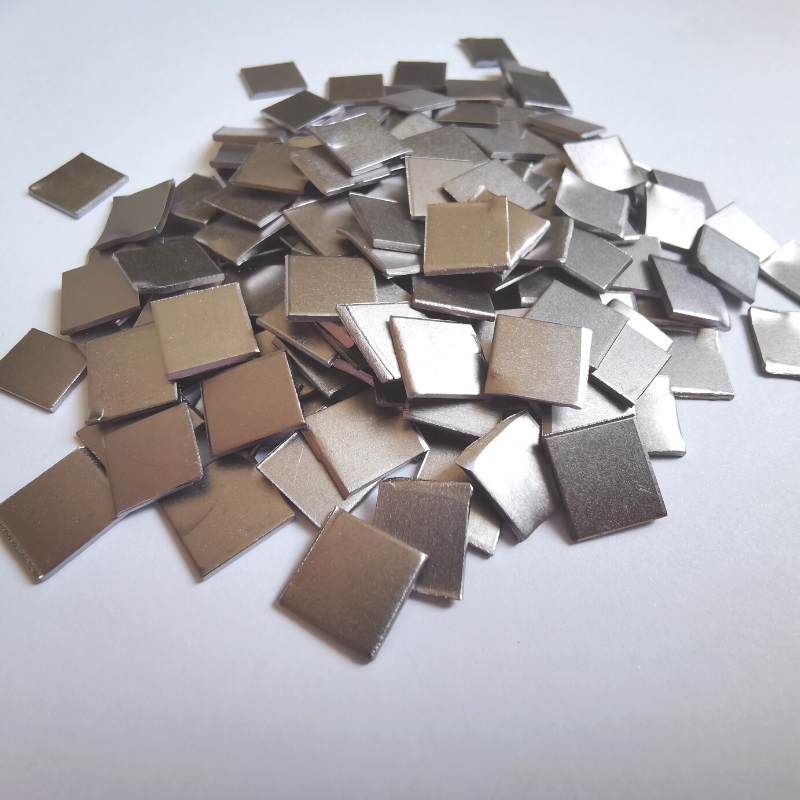

Titanium Aluminum Vanadium sputtering target is fabricated by vacuum melting and casting of Titanium, Aluminum and Vanadium materials. It has high purity and good conductivity.

TiAlV alloy is an alpha+beta alloy. The aluminum stabilizes and strengthens the alpha phase, so raising the beta-transus temperature, as well as reducing the density of the alloy.

The vanadium is a beta stabilizer, and provides a greater amount of the more ductile beta phase during hot working. It is is an excellent material for sheet fabrications, brackets and fasteners in aircraft industry, where lightness and high strength are required. Its easy forgeability and strength at moderate temperature has led to extensive use as compressor blades and discs in gas-turbine engines and as fan blades in the most recent turbofan engines. An entirely new range of cost and weight saving components for both airframes and engines are now being developed using superplastic forming and diffusion bonding processes, for which this alloy is ideal. Industries other than the aircraft industry have used for steam-turbine blades and lacing wire, axial and radial-flow gas compressor discs, springs for corrosion resistance, data logging capsules for oil and mineral exploration, etc. A growing use is as an implant material. Its excellent biocompatibility and good fatigue strength in body fluids make it ideal for the replacement of hip and knee joints, for bone screws, and for other surgical devices.

Rich Special Materials is a Manufacturer of Sputtering Target and could produce Titanium Aluminum Vanadium Sputtering Materials according to Customers’ specifications. For more information, please contact us.

Product detail pictures:

Related Product Guide:

We've one of the most innovative manufacturing devices, experienced and qualified engineers and workers, recognized good quality handle systems and also a friendly experienced income team pre/after-sales support for Factory wholesale Aluminum Sputtering Target - Tialv Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich , The product will supply to all over the world, such as: Lahore, Amsterdam, Egypt, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality products. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our products and services, please do not hesitate to contact us!

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.