2021 High quality Primary Source - Cocraly Alloy Sputtering Target High Purity Thin Film PVD Coating Custom Made – Rich

2021 High quality Primary Source - Cocraly Alloy Sputtering Target High Purity Thin Film PVD Coating Custom Made – Rich Detail:

Cobalt Chromium Aluminum Yttrium Sputtering Target Description

Cobalt Chromium Aluminum Yttrium sputtering target is a Cobalt-based alloy with addition of Chromium Aluminum and Yttrium elements. It exhibits great corrosion resistant behavior in fused salt medium (sodium sulfate, sodium nitrate, sodium carbonate, calcium sulfate, calcium sulfate, sodium chloride potassium chloride, sodium chloride sodium sulfate) at elevated temperatures. Chromium Aluminum Yttrium could have different ratios, depending on the operational environment of the layers. Usually, the alloy would display biphasic structure while the content of Chromium is 20-40%(wt, Aluminum 5-20%(wt), and Yttrium 0.5%(wt).

Cobalt Chromium Aluminum Yttrium targets could be deposited on the surface of high temperature components used in aerospace, aircraft, and gas turbine industries. This kind of layer could prolong the service life by ten thousand hours.

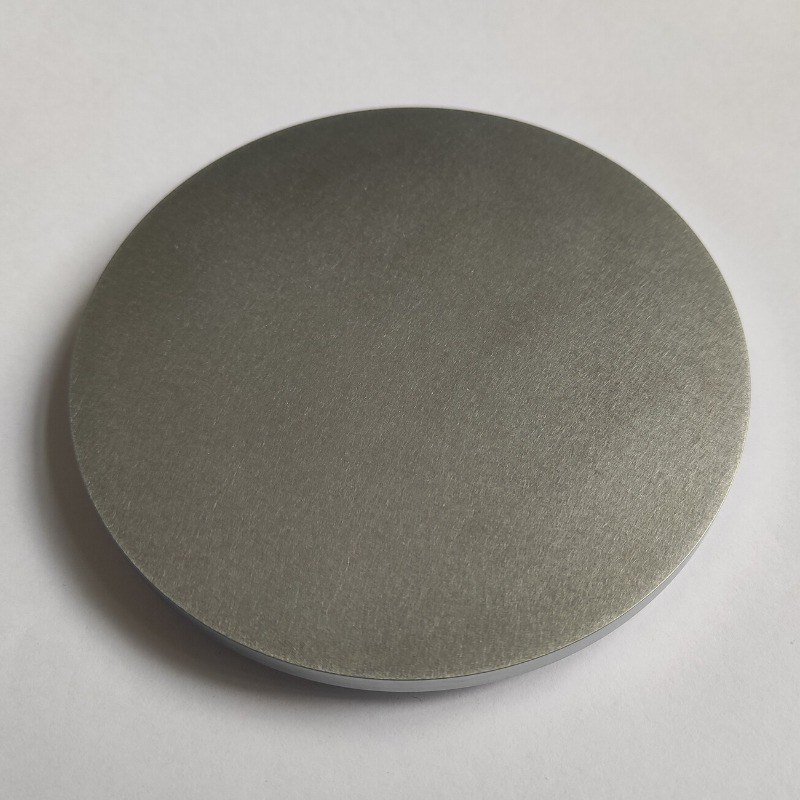

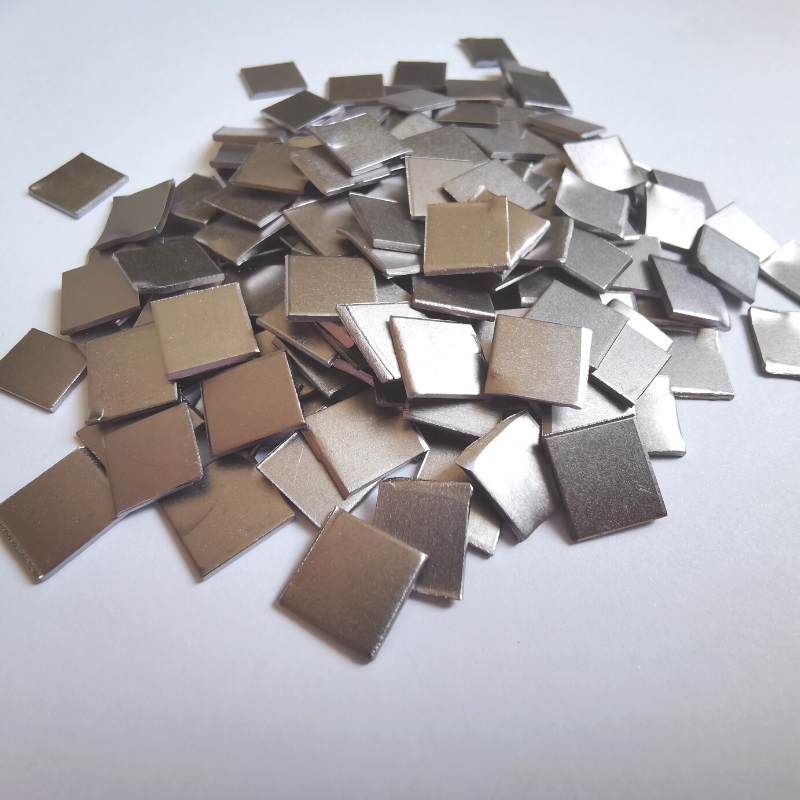

Cobalt Chromium Aluminum Yttrium Sputtering Target Packaging

Our CoCrAlY sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Get Contact

RSM’s Cobalt Chromium Aluminum Yttrium sputtering targets are of ultra-high purity and uniform. They are available in various forms, purities, sizes, and prices. We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for 2021 High quality Primary Source - Cocraly Alloy Sputtering Target High Purity Thin Film PVD Coating Custom Made – Rich , The product will supply to all over the world, such as: Georgia, Lithuania, Niger, Due to good quality and reasonable prices, our items have been exported to more than 10 countries and regions. We are looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!