Rapid Delivery for Vanadium Ingot - Tialsi Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich

Rapid Delivery for Vanadium Ingot - Tialsi Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich Detail:

Titanium Aluminum Silicon Sputtering Target Description

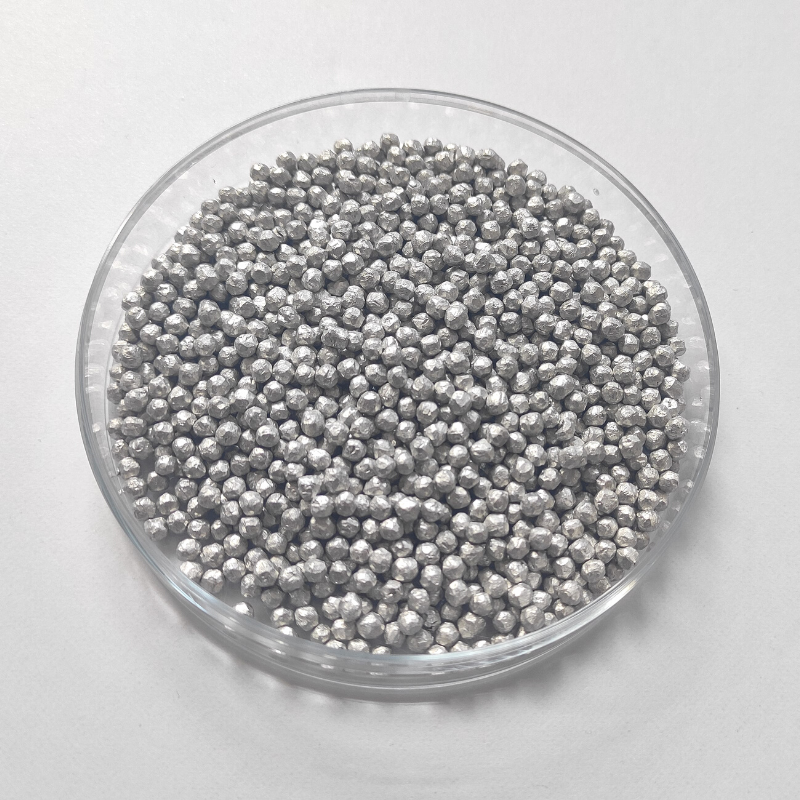

Titanium Aluminum Silicon sputtering target is fabricated by means of power metallurgy.

Titanium Aluminum Silicon alloy in conventionally used in manufacturing automotive engine. It has excellent high-temperature suitability and wear resistance. The application of Ti-Al-Si alloy could significantly prolong engine components’ life for about 35%. As for its application in motorcycle and automotive wheel, it exhibits better castability, machinability , fatigue resistance and impact toughness than A356 Aluminum.

A rapidly solidified aluminum alloy could be obtained by a rapid solidification process called “melt spinning”, which generates superior properties in comparison with conventional aluminum alloy, together with fine-grained microstructure and more flexibility in alloying. It is a potential material in aircraft industry to replace Titanium base alloy used in 150-300℃.

During the deposition process of TiAlSi targets, TiAlSi/TiAlSiN could be formed individually as a multi-layer of high-quality crystalline layers with mostly cubic structures. These multi-layer coatings have have made these materials for hard coatings to increase the lifetime of instruments utilized for harsh environments.

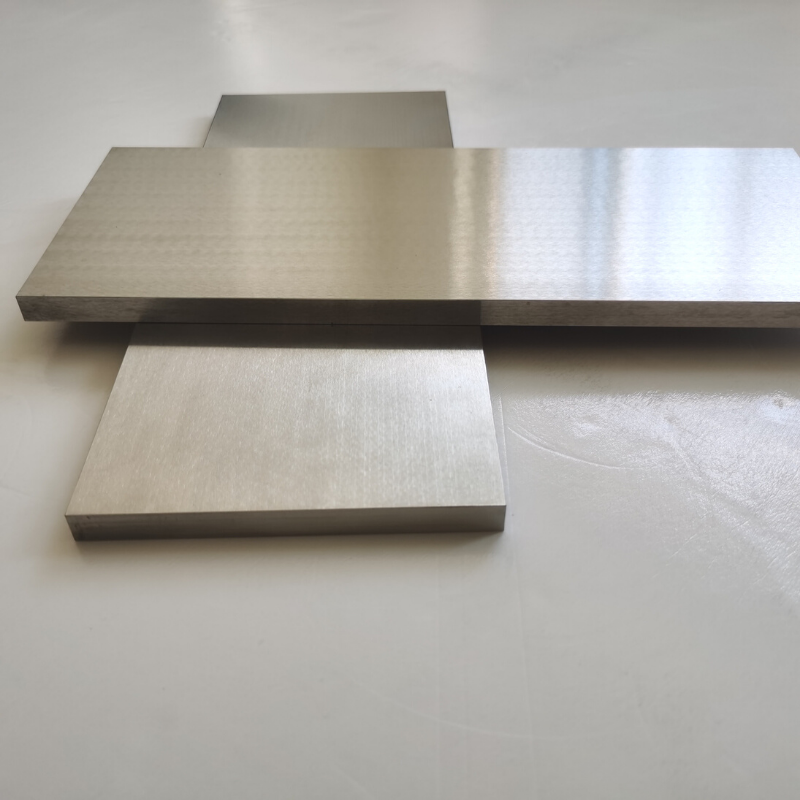

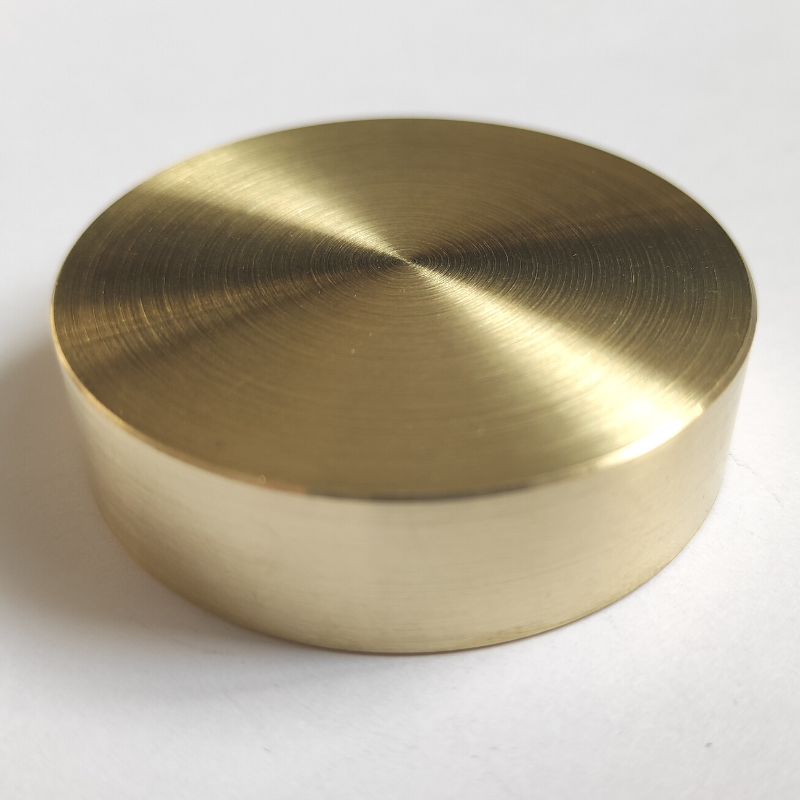

Titanium Aluminum Silicon Sputtering Target Packaging

Our Titanium Aluminum Silicon sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Get Contact

RSM’s Titanium Aluminum Silicon sputtering targets are of ultra-high purity and uniform. They are available in various forms, purities, sizes, and prices. We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.

Product detail pictures:

Related Product Guide:

To create more benefit for buyers is our business philosophy; shopper growing is our working chase for Rapid Delivery for Vanadium Ingot - Tialsi Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich , The product will supply to all over the world, such as: Ethiopia, Croatia, Moldova, We are always creating new technology to streamline the production, and provide goods with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!