OEM/ODM Factory Niv Sputtering Target - China Factory for Magnetron Sputtering Coating Materials with Different Sputtering Targets – Rich

OEM/ODM Factory Niv Sputtering Target - China Factory for Magnetron Sputtering Coating Materials with Different Sputtering Targets – Rich Detail:

We’ve been also concentrating on bettering the things management and QC method in order that we could continue to keep terrific benefit inside the fiercely-competitive company for China Factory for Magnetron Sputtering Coating Materials with Different Sputtering Targets, We’ve expanded our business enterprise into Germany, Turkey, Canada, U. S. A. , Indonesia, India, Nigeria, Brazil and some other regions of your environment. We have been doing work hard being one with the ideal worldwide suppliers.

We’ve been also concentrating on bettering the things management and QC method in order that we could continue to keep terrific benefit inside the fiercely-competitive company for China Sputtering Target and Magnetron Target, Our main objectives are to supply our customers worldwide with good quality, competitive price, satisfied delivery and excellent services. Customer satisfaction is our main goal. We welcome you to visit our showroom and office. We have been looking forward to establish business relation with you.

Titanium diboride TiB2 powder is gray or gray-black, with a hexagonal (AlB2) crystal structure, with a melting point of 2980°C and high hardness. The anti-oxidation temperature of titanium diboride in the air can reach 1000℃, and it is stable in HCl and HF acid.

Titanium diboride could be applied to production of molten metal crucible and electrode of electrolytic tank due to its resistance corrosion from molten metal. It is also kind of conductive ceramic material, which is one of main raw materials for conductive evaporation boat for vacuum coating purpose. TiB2 is raw material for ceramic cutting tools and molds, which apply to make knife, wortle, extrusion die, blast nozzle and sealing elements. Titanium diboride could compound with TiC, TiN, SiC to form multielement composite ceramic material. It is for various high-temperature parts and function parts as high temperature crucible and engine parts. It is one of best protection material for Armor. TiB2 is cathode coating for aluminium electrolysis cell. It is used in preparing thermal PTC ceramic material and soft PTC material. It is also great enhancer for Al, Fe, Cu and other metal materials.

| Mat. | Purity | Density(g/cm3) | Grain(μm) | T.C.((W/(m·k)) | CTE[1/K] |

| TiB2 | 99.7 | 4.40 | 2 | 64 | 7.4Χ10-6 |

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Titanium Diboride Sputtering Materials according to Customers’ specifications. For more information, please contact us.

We’ve been also concentrating on bettering the things management and QC method in order that we could continue to keep terrific benefit inside the fiercely-competitive company for China Factory for Magnetron Sputtering Coating Materials with Different Sputtering Targets, We’ve expanded our business enterprise into Germany, Turkey, Canada, U. S. A. , Indonesia, India, Nigeria, Brazil and some other regions of your environment. We have been doing work hard being one with the ideal worldwide suppliers.

China Factory for China Sputtering Target and Magnetron Target, Our main objectives are to supply our customers worldwide with good quality, competitive price, satisfied delivery and excellent services. Customer satisfaction is our main goal. We welcome you to visit our showroom and office. We have been looking forward to establish business relation with you.

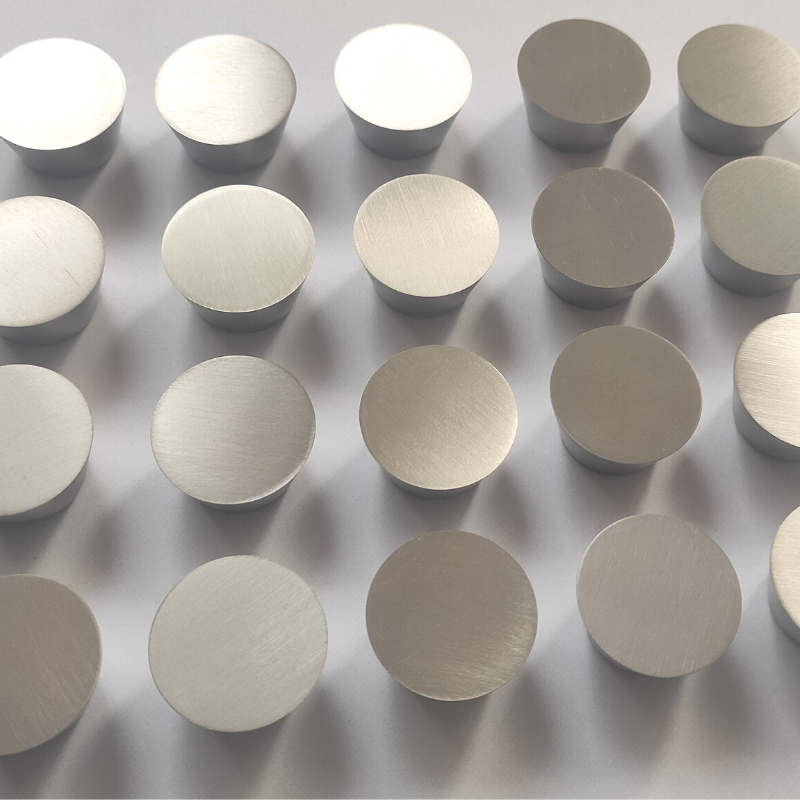

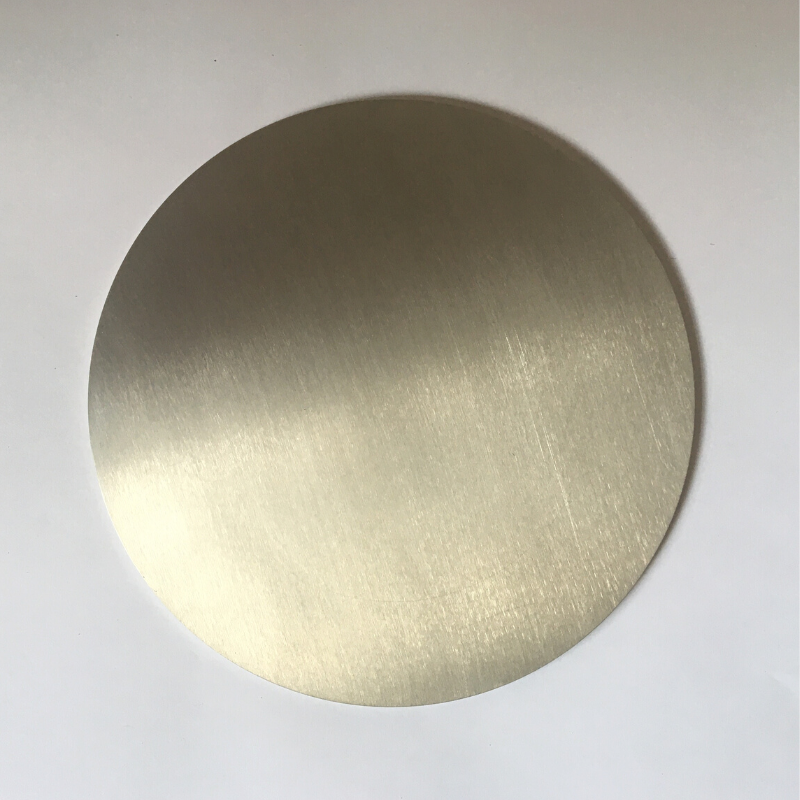

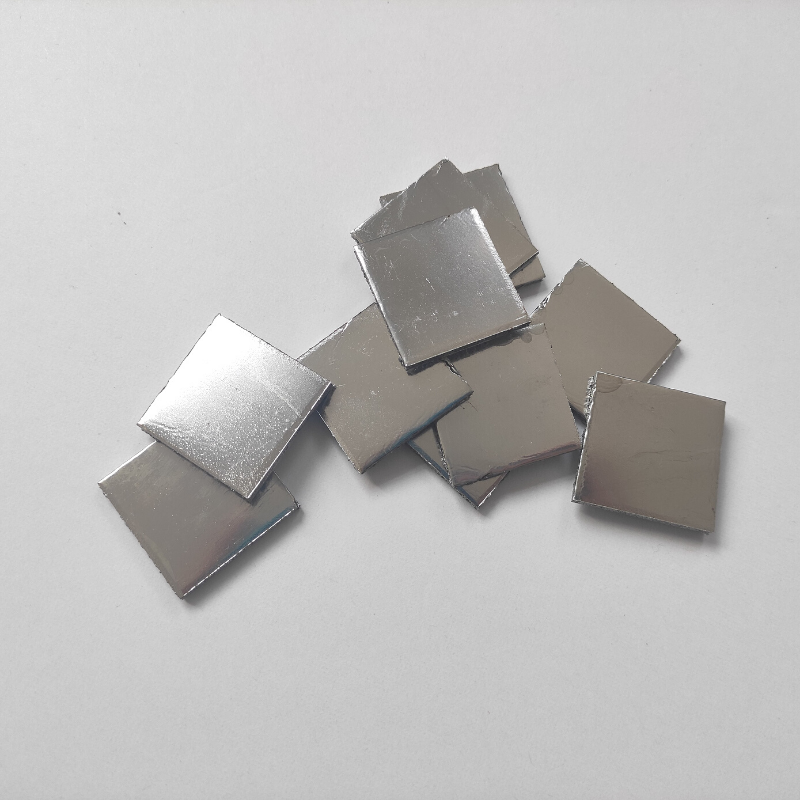

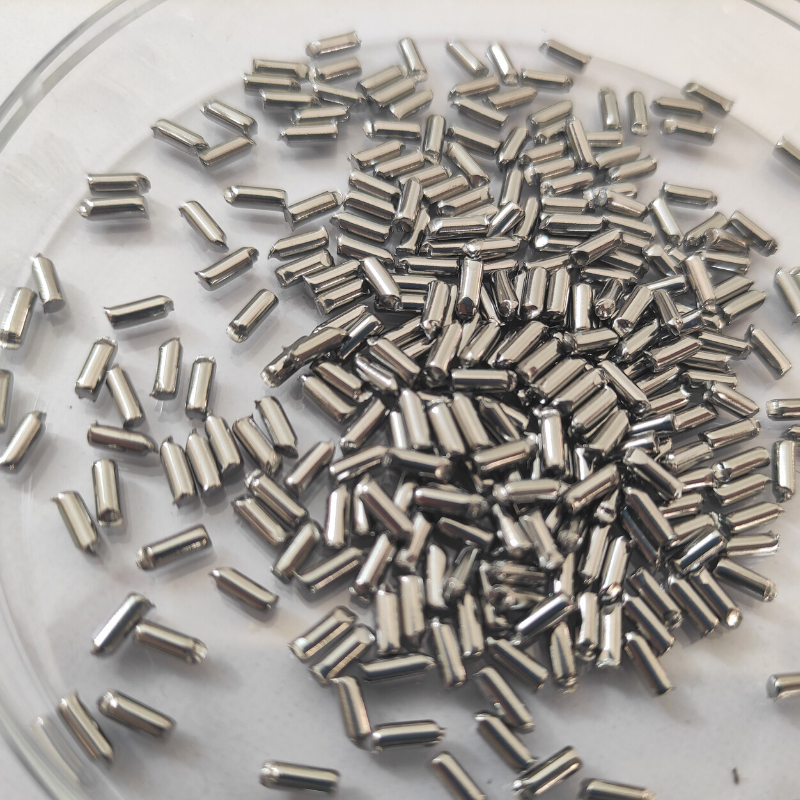

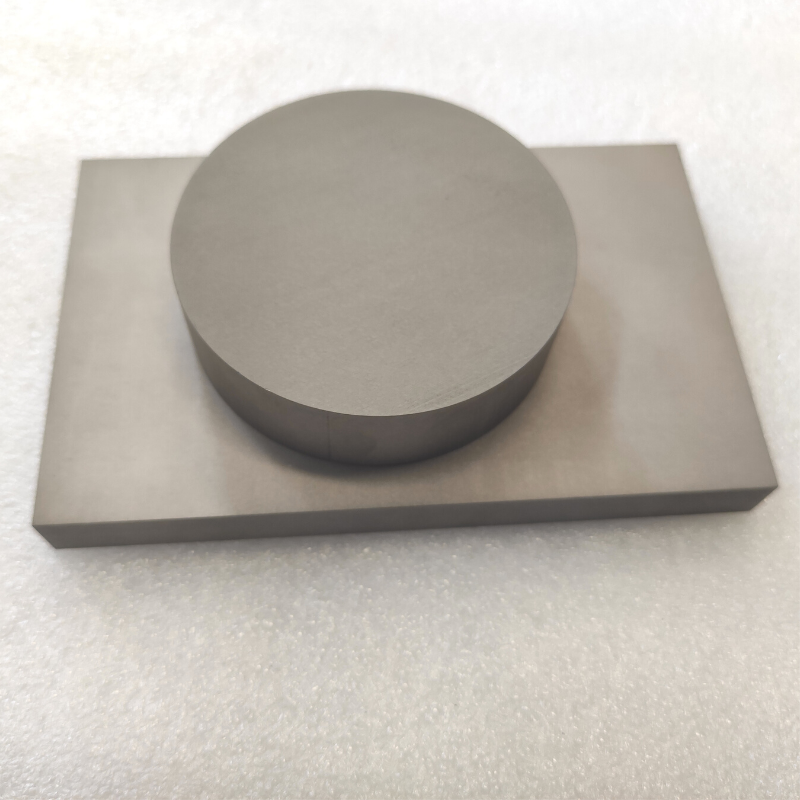

Product detail pictures:

Related Product Guide:

We insist on offering premium quality manufacturing with superior business concept, honest product sales as well as finest and fast assistance. it will bring you not only the good quality product or service and huge profit, but the most significant is to occupy the endless market for OEM/ODM Factory Niv Sputtering Target - China Factory for Magnetron Sputtering Coating Materials with Different Sputtering Targets – Rich , The product will supply to all over the world, such as: belarus, Honduras, Nicaragua, We have a professional sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique products.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.