Low MOQ for Cocrw Sputtering Target - Fesi Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich

Low MOQ for Cocrw Sputtering Target - Fesi Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich Detail:

Iron Silicon alloy usually has the Silicon content of 0.5-4%. It has lower hysteresis loss than pure Iron and high resistivity, and could be applied in magnetic field. In order to reduce eddy current loss, Iron Silicon alloy is often hot rolled into 0.35-0.5mm sheets (silicon lamination). Silicon lamination is extensively used in electric power industry, so it is also called electrical steel.

Ferrosilicon alloy offers excellent magnetic property and low saturation magnetization. It has coarse grain size, high magnetic permeability and resistivity, low coercive force and core loss. Silicon could promote graphitization of Carbon in steel and effectively prevent the magnetic aging phenomenon. Ferrosilicon alloy has high stability and could be applied extreme environment.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Iron Silicon Sputtering Materials according to Customers’ specifications. For more information, please contact us.

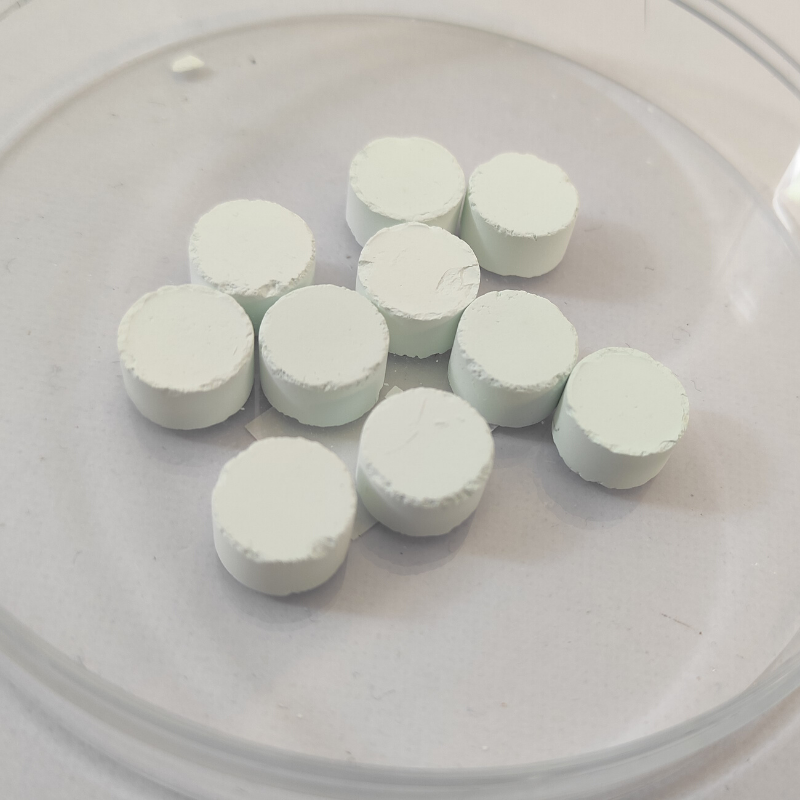

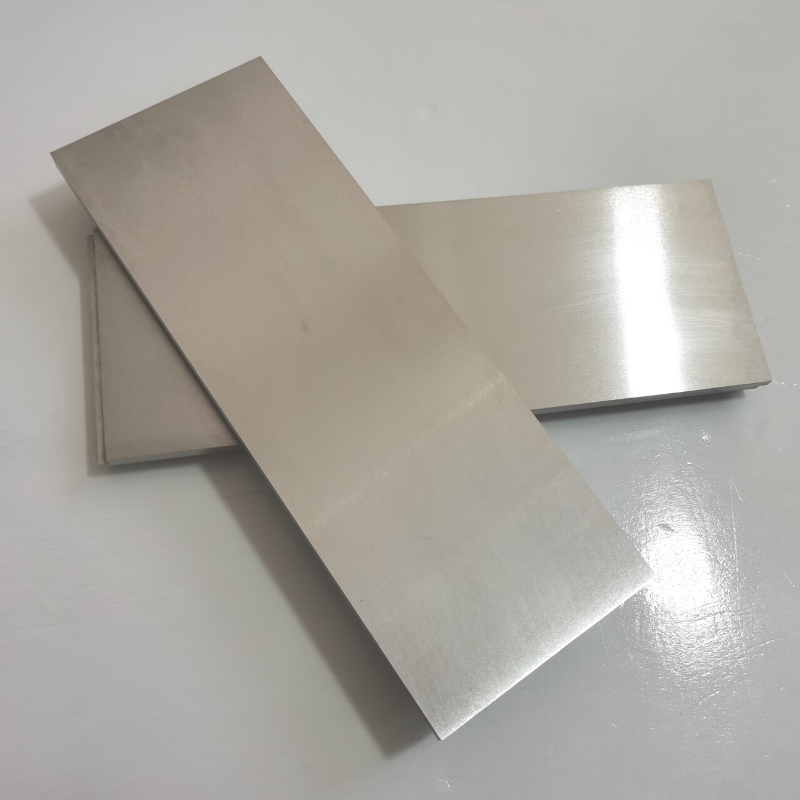

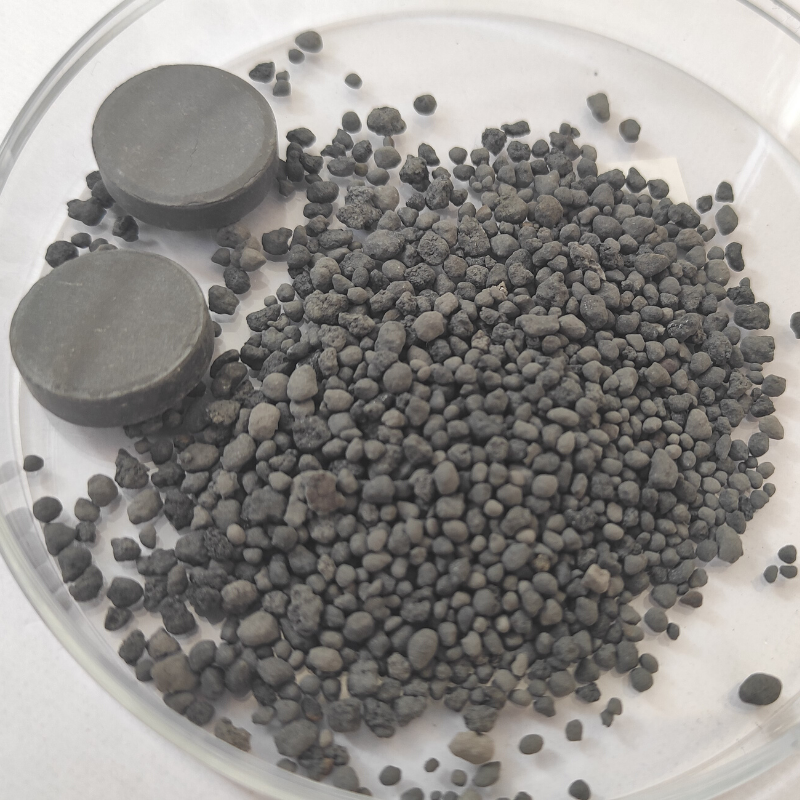

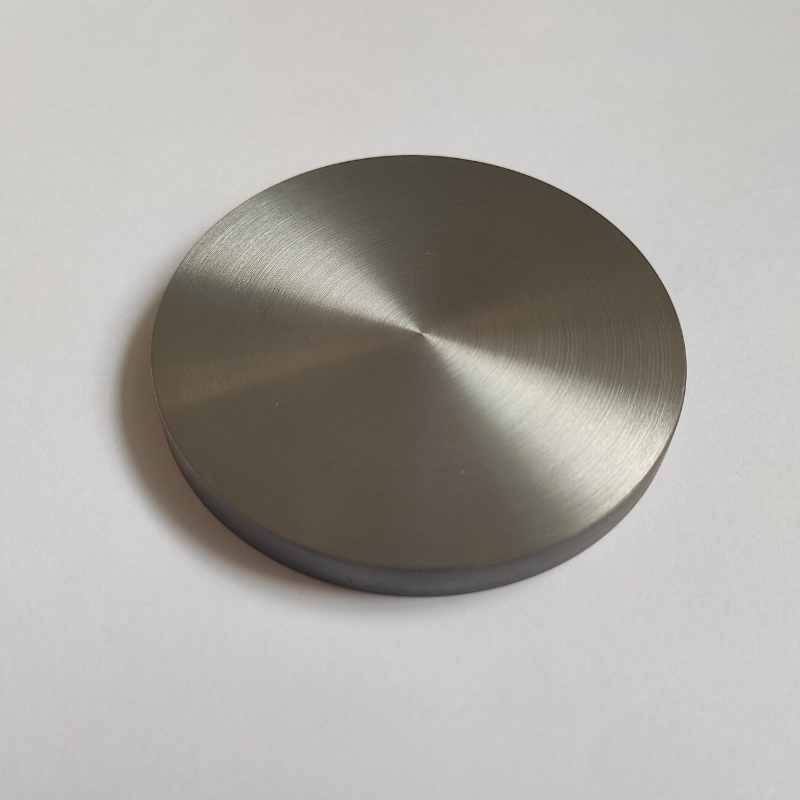

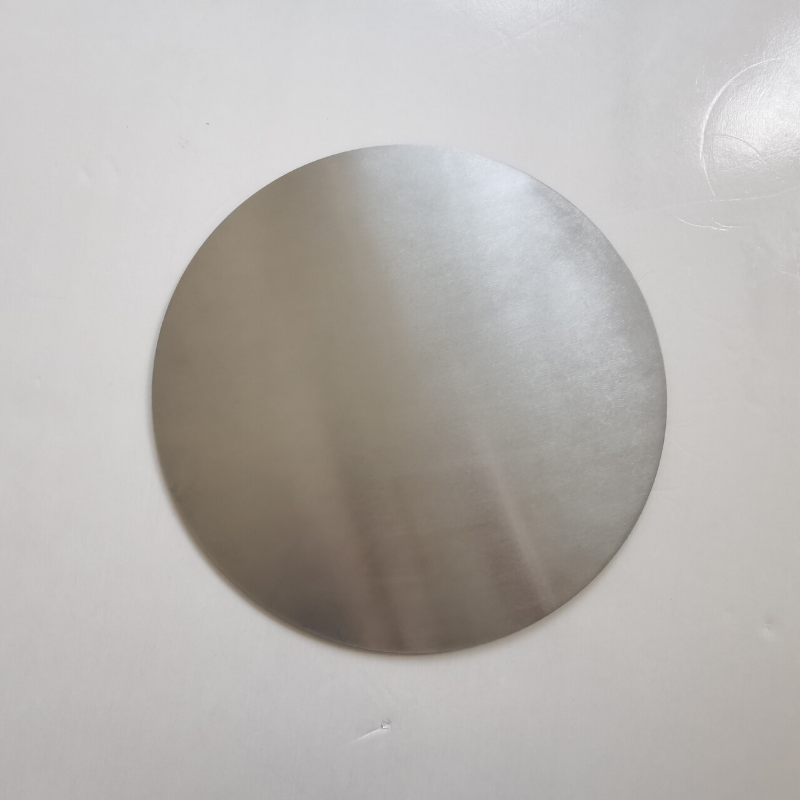

Product detail pictures:

Related Product Guide:

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for Low MOQ for Cocrw Sputtering Target - Fesi Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich , The product will supply to all over the world, such as: Bahamas, Buenos Aires, Iceland, If any product meed your demand, remember to feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality merchandise, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.