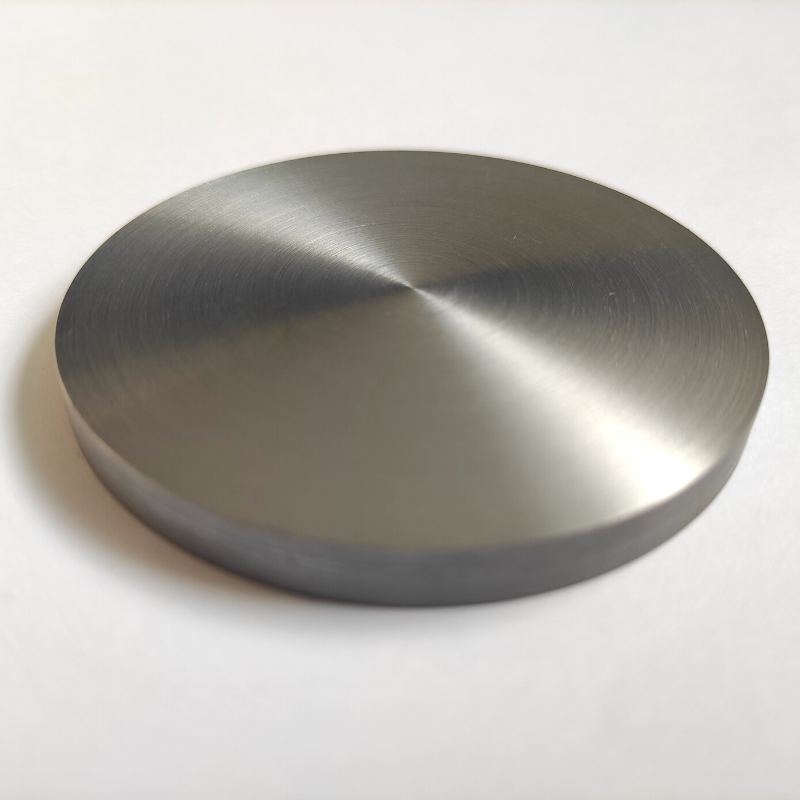

High Performance Samarium Sm Sputtering Target - Fecr Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich

High Performance Samarium Sm Sputtering Target - Fecr Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich Detail:

Iron Chromium alloy sputtering target is fabricated by means of vacuum melting or powder metallurgy. Fe-Cr alloy has been used as the basic ingredient in the steel production industry. Adding Chromium into steel improves its oxidation and corrosion resistance, while Chromium added into Iron casting would raise the hardness and improve the wear resistance and machinability.

The iron chromium sputtering target is used for thin film deposition, decoration, semiconductor, display, LED and photovoltaic devices, functional coating as nicely as other optical information storage space industry, glass coating industry like car glass and architectural glass, optical communication, etc.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Iron Chronium Sputtering Materials according to Customers’ specifications. For more information, please contact us.

Product detail pictures:

Related Product Guide:

Sticking to the belief of "Creating products of high quality and making friends with people from all over the world", we always put the interest of customers in the first place for High Performance Samarium Sm Sputtering Target - Fecr Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich , The product will supply to all over the world, such as: Belgium, Dubai, Hongkong, With the support of our highly experienced professionals, we manufacture and supply best quality products. These are quality tested at various occasions to ensure only flawless range is delivered to customers, we also customize the array as per the need of customers to meet the requirement of customers.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.