Good quality Al/Cu Sputtering Target - China Professional Manufacture High purity Electrolytic nickel board Ni Ingot Sputtering Targets Electrolysis Nickel Ingot – Rich

Good quality Al/Cu Sputtering Target - China Professional Manufacture High purity Electrolytic nickel board Ni Ingot Sputtering Targets Electrolysis Nickel Ingot – Rich Detail:

China Professional Manufacture High purity Electrolytic nickel board Ni Ingot Sputtering Targets Electrolysis Nickel Ingot,

,

Chromium cobalt sputtering target from Rich Special Materials is a silvery alloy sputtering material containing Cr and Co.

Chromium is a chemical element that originated from the Greek ‘chroma’, meaning color. It was early used before 1 AD and discovered by Terracotta Army. “Cr” is the canonical chemical symbol of chromium. Its atomic number in the periodic table of elements is 24 with a location at Period 4 and Group 6, belonging to the d-block. The relative atomic mass of chromium is 51.9961(6) Dalton, the number in the brackets indicating the uncertainty.

Cobalt is a chemical element that originated from the German word ‘kobald’, meaning goblin. It was first mentioned in 1732 and observed by G. Brandt. “Co” is the canonical chemical symbol of cobalt. Its atomic number in the periodic table of elements is 27 with a location at Period 4 and Group 9, belonging to the d-block. The relative atomic mass of cobalt is 58.933195(5) Dalton, the number in the brackets indicating the uncertainty.

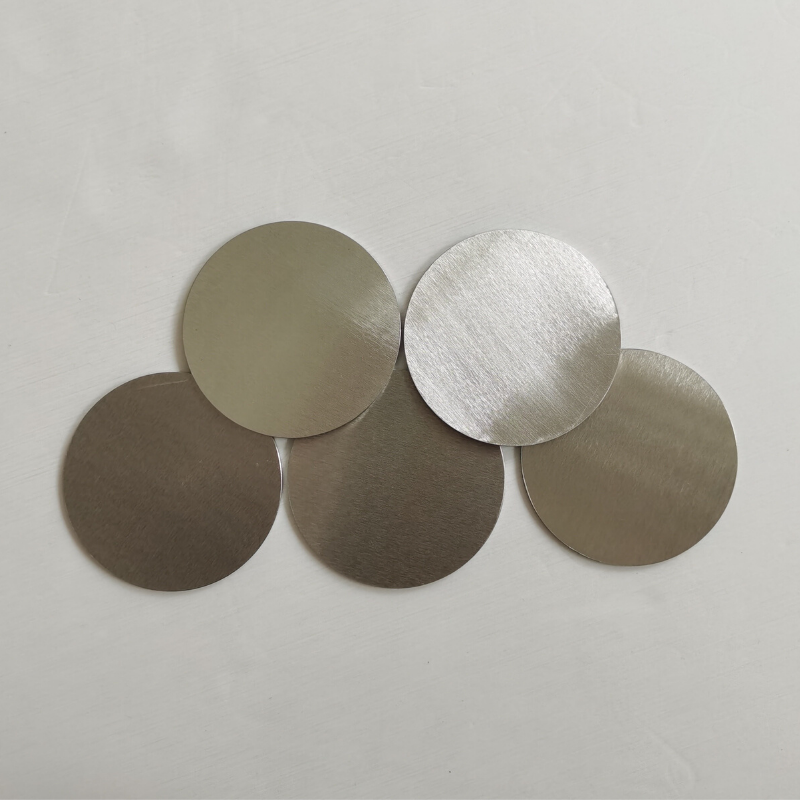

Chronium Cobalt Sputtering Targets are manufactured by means of Vacuum Melting and PM. CrCo has superior specific strength and has been used in various fields where high wear-resistance was needed including aerospace industry, cutlery, bearings, blades, etc.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Chronium Cobalt Sputtering Materials according to Customers’ specifications. For more information, please contact us.

Nickel is a silver-white metal with atomic weight of 58.69, density of 8.9g/cm³, melting point of 1453℃, boiling point of 2730℃. It is hard, malleable, ductile, and readily soluble in dilute acids, but is not affected by alkalis.

Nickel is widely used in the sputtering target industry; it could produce film coatings with attractive appearance and great corrosion resistance. Nickel powder is often used as the catalyst. Nickel is one of only four elements that are magnetic at or near room temperature, when it is alloyed with Aluminum and Cobalt, the magnetic force would be stronger. It is an important candidate for tube grid, high temperature component for vacuum furnace and X-ray sputtering targets.

Product detail pictures:

Related Product Guide:

We emphasize enhancement and introduce new solutions into the market just about every year for Good quality Al/Cu Sputtering Target - China Professional Manufacture High purity Electrolytic nickel board Ni Ingot Sputtering Targets Electrolysis Nickel Ingot – Rich , The product will supply to all over the world, such as: Portland, moldova, Moscow, Our items are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our merchandise and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!