Factory Free sample Hf Pellets - Cral Alloy Sputtering Target High Purity Thin Film PVD Coating Custom Made – Rich

Factory Free sample Hf Pellets - Cral Alloy Sputtering Target High Purity Thin Film PVD Coating Custom Made – Rich Detail:

The fabrication of Chromium Aluminum Sputtering Targets comprises the following steps:

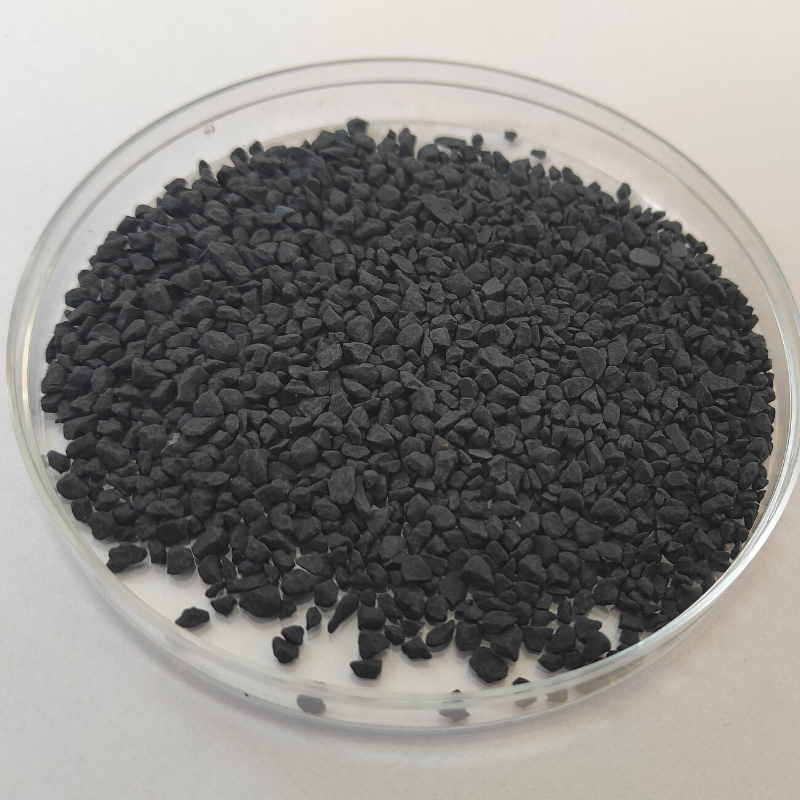

1. Powder grinding and mixing.

2. Hot isostatic pressing treatment to get semi-finished products.

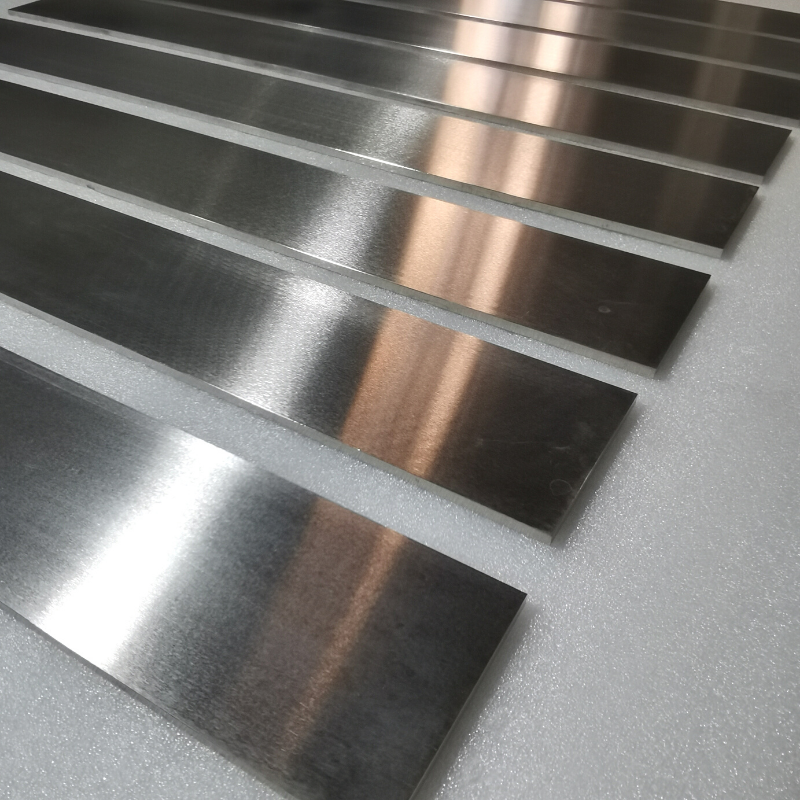

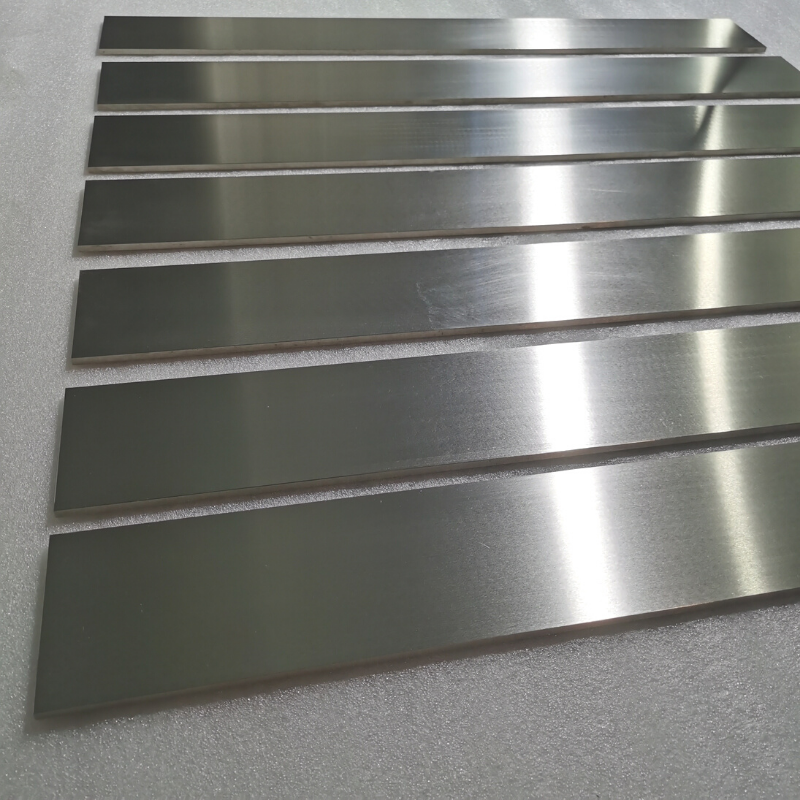

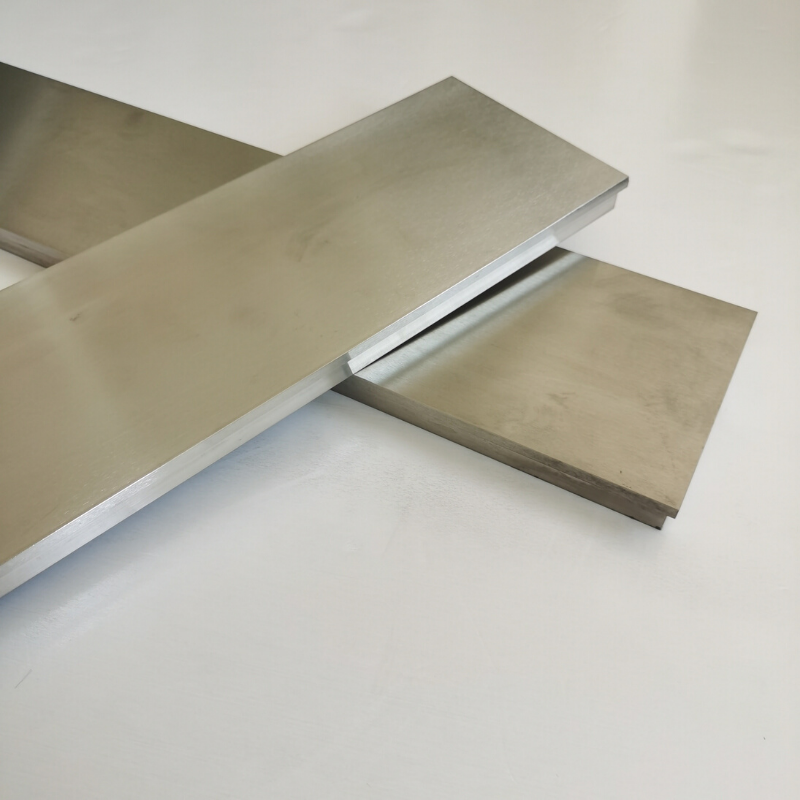

3. Machining the rough chromium aluminum alloy sputtering target material to obtain the chromium aluminum alloy sputtering target material.

During the deposition process of CrAl sputtering targets, a hard Aluminium-Chrom-Nitrid (AlCrN) coating is formed. This coating shows high hardness and oxidation resistance properties even at high temperature. The cutters could run at high feeds to increase productivity and raise quality when using CNC machines.

Our typical AlCr targets and their properties

|

Cr-70Al at% |

Cr-60Al at% |

Cr-50Al at% |

|

|

Purity (%) |

99.8/99.9/99.95 |

99.8/99.9/99.95 |

99.8/99.9/99.95 |

|

Density(g/cm3) |

3.7 |

4.35 |

4.55 |

|

Grain Size(µm) |

100/50 |

100/50 |

100/50 |

|

Process |

HIP |

HIP |

HIP |

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Chronium Aluminum Sputtering Materials, and other CrAl series(for example:CrAlSi,CrAlTi,CrAlZr, CrAlTa,CrAlW,CrAlY,CrAlCe,etc.) according to Customers’ specifications. Our products feature excellent mechanical properties, homogeneous structure, polished surface with no segregation, pores or cracks. For more information, please contact us.

Our typical AlCr targets and their properties

|

Cr-70Al at% |

Cr-60Al at% |

Cr-50Al at% |

|

|

Purity (%) |

99.8/99.9/99.95 |

99.8/99.9/99.95 |

99.8/99.9/99.95 |

|

Density(g/cm3) |

3.7 |

4.35 |

4.55 |

|

Grain Size(µm) |

100/50 |

100/50 |

100/50 |

|

Process |

HIP |

HIP |

HIP |

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Aluminum Chromium Sputtering Materials according to Customers’ specifications. Our products feature excellent mechanical properties, homogeneous structure, polished surface with no segregation, pores or cracks. For more information, please contact us.

Product detail pictures:

Related Product Guide:

Our staff through skilled training. Skilled skilled knowledge, potent sense of company, to satisfy the provider requirements of consumers for Factory Free sample Hf Pellets - Cral Alloy Sputtering Target High Purity Thin Film PVD Coating Custom Made – Rich , The product will supply to all over the world, such as: France, Mecca, Porto, Establish long term and win-win business relationships with all our customers, share the success and enjoy the happiness of spreading our products to the world together. Trust us and you will gain more. Please feel free to contact us for more information, we assure you of our best attention at all times.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!