Factory directly Pb Ingot - Cralsi Alloy Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich

Factory directly Pb Ingot - Cralsi Alloy Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich Detail:

Chronium Aluminum Silicon Sputtering Target Description

The fabrication of Chronium Aluminum Silicon Sputtering Targets comprises the following steps:

1.Vacuum melting of Silicon, Aluminum and Chronium to obtain step alloys.

2.Powder grinding and mixing.

3.Hot isostatic pressing treatment to obtain the chromium Aluminum silicon alloy sputtering target.

Chronium Aluminum Silicon Sputtering Targets are extensively used in cutting tools and molds, owing to its wear resistance and high temperature oxidation resistance to improve the film performance.

An amorphous Si3N4 phase would be formed during the process of PVD of CrAlSi targets. Due to the incorporation of amorphous Si3N4 phase, the growth of the grain size could be restrained and improve the high temperature oxidation resistance property.

Chronium Aluminum Silicon Sputtering Target Packaging

Our Chronium Aluminum Silicon sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation

Get Contact

RSM’s Chronium Aluminum Silicon sputtering targets are of ultra-high purity and uniform. They are available in various forms, purities, sizes, and prices. We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.

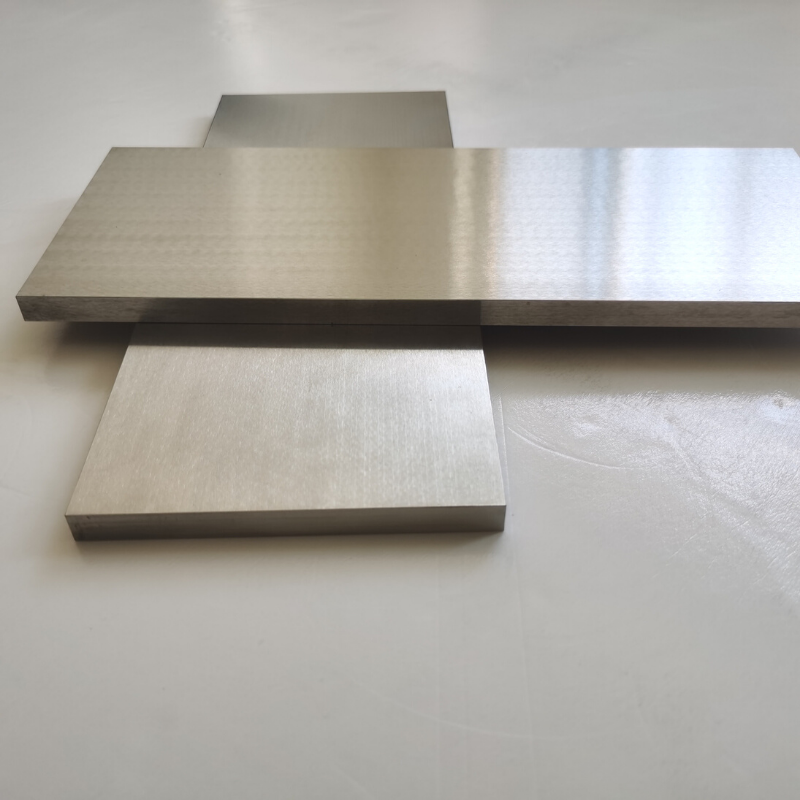

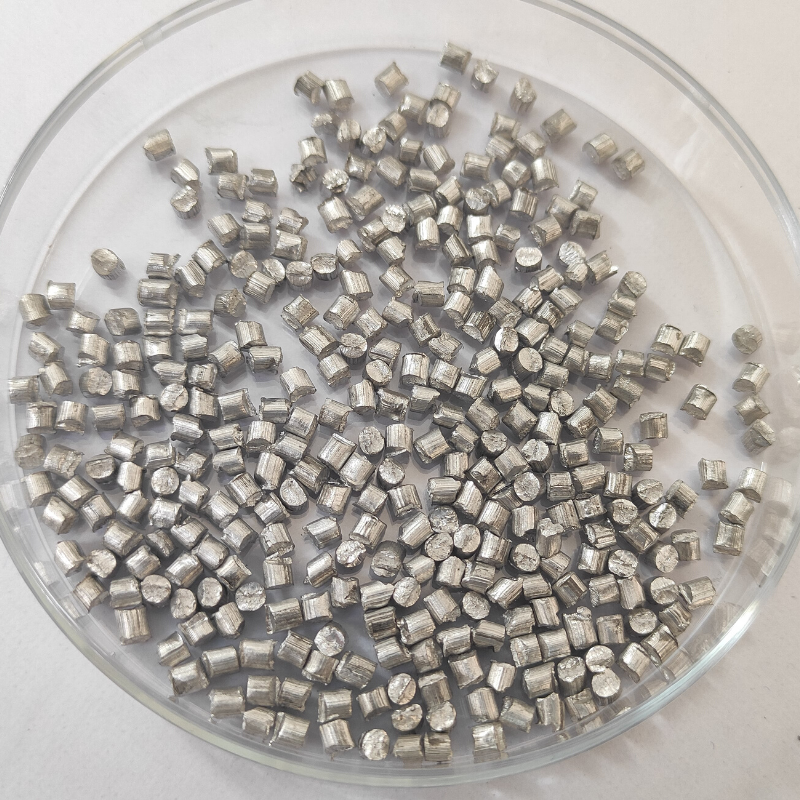

Product detail pictures:

Related Product Guide:

We now have a highly efficient crew to deal with inquiries from clients. Our intention is "100% shopper pleasure by our merchandise quality, price tag & our staff service" and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of Factory directly Pb Ingot - Cralsi Alloy Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich , The product will supply to all over the world, such as: Casablanca, United Arab Emirates, Paris, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.