Factory Cheap Oxide Target - Nicr Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich

Factory Cheap Oxide Target - Nicr Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich Detail:

Production Details

With its good performance of antioxidation and corrosion resisting, NiCr alloy sputtering target It is extensively used in many industrial applications, such as Low-E glass, micro-electronics, magnetic recording, semiconductor, and thin film resistor.

Nickel Chromium Sputtering Target is widely used in the glass coating industry, including automotive glass coating, in order to reduce the reflection, increase the transmittance of light, and solve the ghost image problem. In addition, PVD coating could slow the rate of aging and extend the useful life of products.

Low-E, or low-emissivity, glass was created to minimize the amount of infrared and ultraviolet light that comes through your glass, without minimizing the amount of light that enters your home. Low-E glass windows have thin coatings that are transparent and reflect heat, keeping the temperature consistent by reflecting the interior temperatures back inside. Nickel Chromium is often deposited outermost to function as antioxidation and corrosion resisting layer.

Thin film resistor produced by Nickel Chromium alloy has many advantages: high Resistivity, low Temperature Coefficient and high Sensitivity, and widely used in different industries including Resistance Strain Gauge.

Impurity content

|

Purity |

Composition(wt%) |

Impurity(ppm)≤ |

Total metal impurity(ppm) |

||||||

|

Cr |

Fe |

Al |

Si |

C |

N |

O |

S |

||

|

99.5 |

20±1.0 |

2500 |

1000 |

1500 |

150 |

100 |

200 |

100 |

≤5000 |

|

99.7 |

20±1.0 |

1500 |

800 |

1000 |

150 |

100 |

200 |

100 |

≤3000 |

|

99.8 |

20±1.0 |

1200 |

300 |

600 |

150 |

100 |

200 |

100 |

≤2000 |

|

99.9 |

20±1.0 |

600 |

200 |

500 |

100 |

100 |

200 |

50 |

≤1000 |

|

99.95 |

20±1.0 |

200 |

100 |

200 |

100 |

100 |

200 |

50 |

≤500 |

Rich Special Materials has made deep research for Nickel Chromium Alloy ,we could supply Chromium composition from 5%-80%. Typical Composition: Ni-5Cr wt%,Ni-7Cr wt%, Ni-20Cr at%,Ni-20Cr wt%, Ni-30Cr wt%,Ni-40Cr at%, Ni-40Cr wt%,Ni-44Cr wt%, Ni-50Cr wt%,Ni-60Cr wt%, and we could supply different purities 99.5%,99.7%,99.8%,99.9%,99.95%. Our products are widely sold in North America, Europe, Japan, Korea, South Asia and Taiwan and applicated in different industries: Large Area Glass , Automatic, Resistor, Magnetic Recording and Integrated Circuit PVD Coating.

Rich Special Materials is a Manufacturer of Sputtering Target could produce Nickel Chromium Sputtering Materials according to Customers’ specifications. For more information, please contact us.

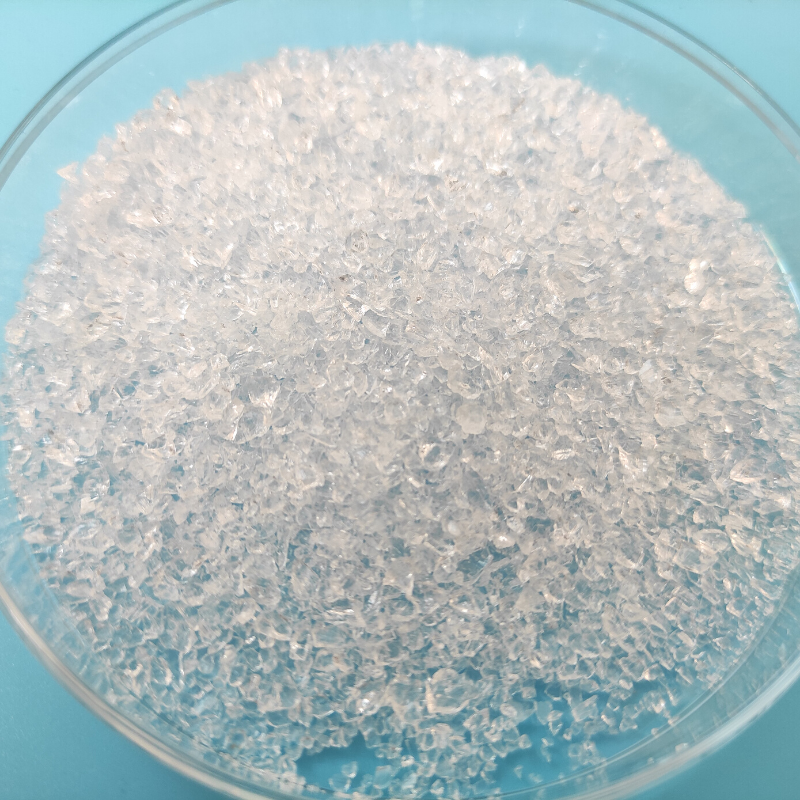

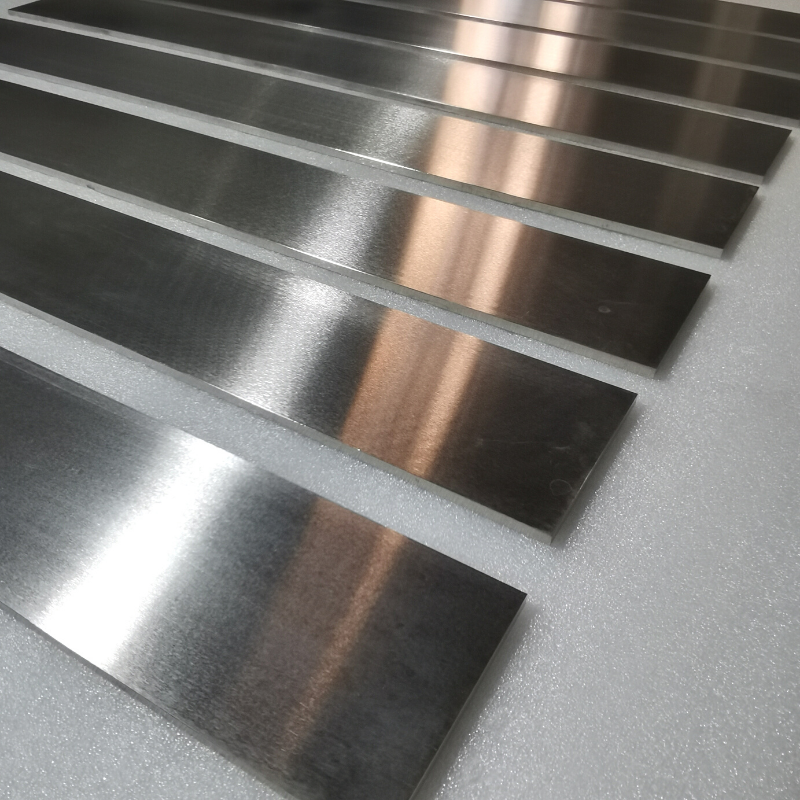

Product detail pictures:

Related Product Guide:

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for Factory Cheap Oxide Target - Nicr Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich , The product will supply to all over the world, such as: Kuala Lumpur, Zimbabwe, Congo, We're your reliable partner in the international markets of our products and solutions. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade solutions in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We're willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.