Competitive Price for Cold Isostatic Pressing - Niti Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich

Competitive Price for Cold Isostatic Pressing - Niti Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich Detail:

Nickel Titanium Sputtering Target Description

Nickel Titanium Sputtering Targets are manufactured by means of Vacuum Melting and PM. Both Martensite and Austenite structure could be observed due to the change of temperature and mechanical stress.

Nickel Titanium alloy is one of the shape memory alloys (SMA). SMA are able to recover their original shape through the appropriate heat or stress exposure after enduring mechanical deformation at a low temperature. SMA coatings show a variety of useful properties: shape memory effect, fracture resistance, super elasticity, elevated strength and ductility. Owing to the unique feature of NiTi thin films, Nickel Titanium Sputtering Targets are extensively applicated in many industries: orthopedic, cardiovascular and orthodontic, surgical instruments, and in neurosurgery.

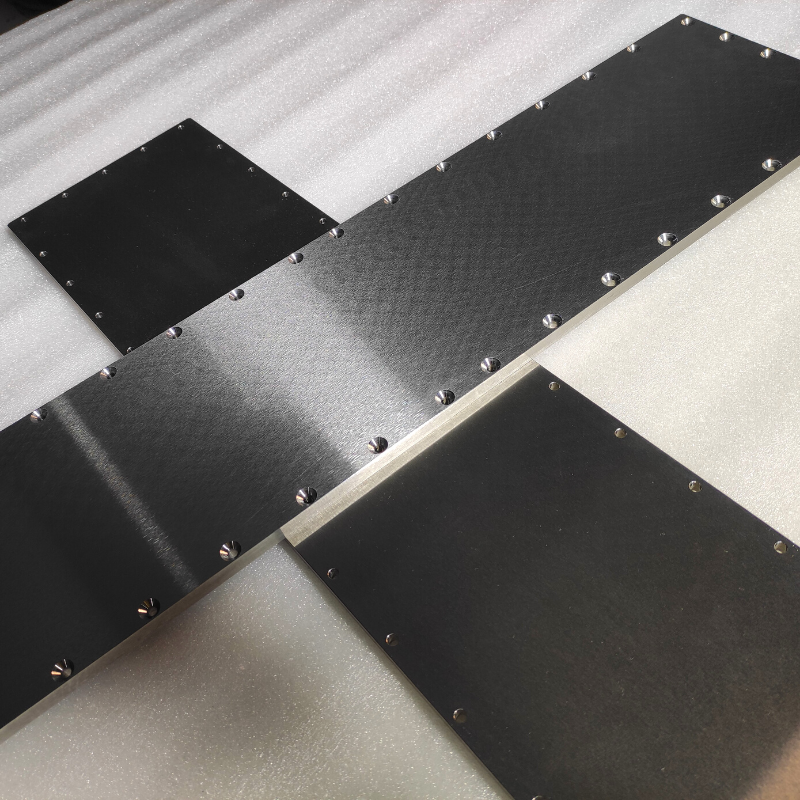

Nickel Titanium Sputtering Target Packaging

Our Nickel Titanium sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

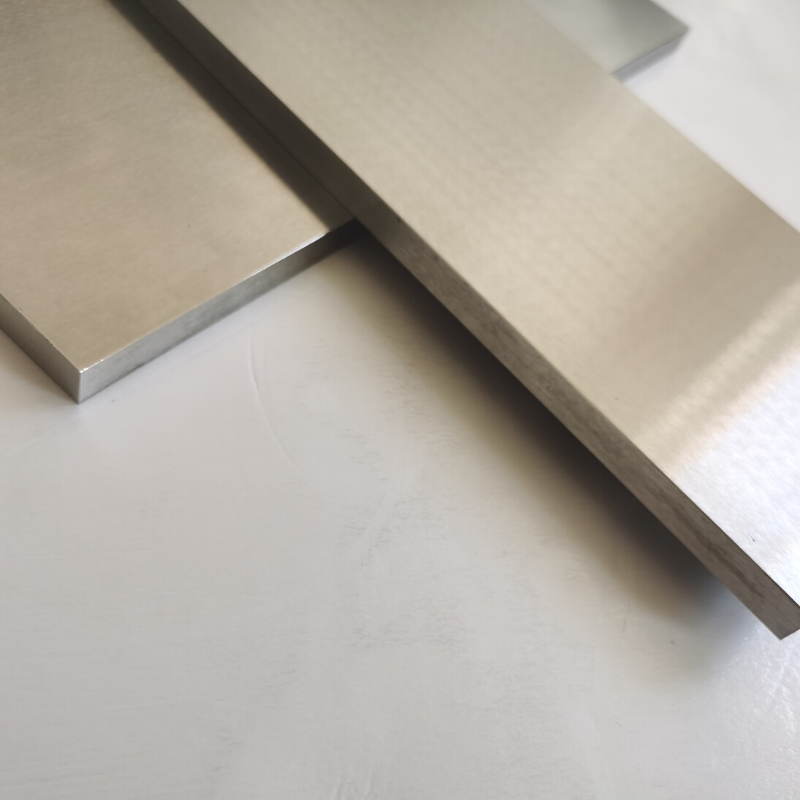

Vanadium Sputtering Target Packaging

Our Vanadium sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Get Contact

RSM’s Nickel Titanium sputtering targets are of ultra-high purity and uniform. They are available in various forms, purities, sizes, and prices. We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for Competitive Price for Cold Isostatic Pressing - Niti Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich , The product will supply to all over the world, such as: Karachi, United Arab Emirates, Nepal, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.