Chinese Professional High Purity Material - CuMn Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich

Chinese Professional High Purity Material - CuMn Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich Detail:

Copper Manganese alloy sputtering target is fabricated by means of vacuum melting. It has homogenous microstructure, high hardness and anti-deformation properties, and long service life. So it could help to reduce manufacturing costs because it is unnecessary to replace the sputter targets at frequent intervals.

Copper Manganese alloy could also be used to produce Manganese brass and Cu-Ni-Mn Alloys. Manganese shows substantial solid solubility in copper and is an effective solid solution strengthening agent. It could noticeably improve the hardness and strength, and corrosion resistance behavior in marine, chloride medium and vapor pressure.

Copper is a chemical element originated from the Old English name coper, which in turn derived from the Latin ‘Cyprium aes’, meaning a metal from Cyprus. It was early used in 9000 BC and discovered by people from the Middle East. “Cu” is the canonical chemical symbol of copper. Its atomic number in the periodic table of elements is 29 with location at Period 4 and Group 11, belonging to the d-block. The relative atomic mass of copper is 63.546(3) Dalton, the number in the brackets indicating the uncertainty.

Manganese is a chemical element originated from Either the Latin ‘magnes’, meaning magnet or from the black magnesium oxide, ‘magnesia nigra’. It was first mentioned in 1770 and observed by O. Bergman. The isolation was later accomplished and announced by G. Gahn. “Mn” is the canonical chemical symbol of manganese. Its atomic number in the periodic table of elements is 25 with location at Period 4 and Group 7, belonging to the d-block. The relative atomic mass of manganese is 54.938045(5) Dalton, the number in the brackets indicating the uncertainty.

A wide range of special materials specialising in the manufacture of sputtering targets, we can produce copper and manganese sputtering materials to customer specifications. For more information, please contact us.

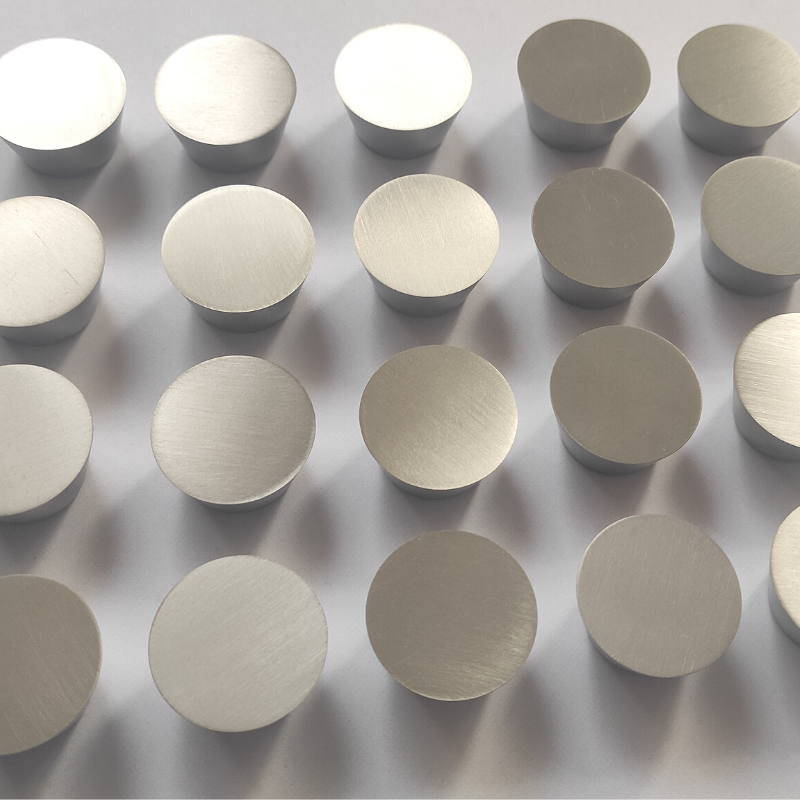

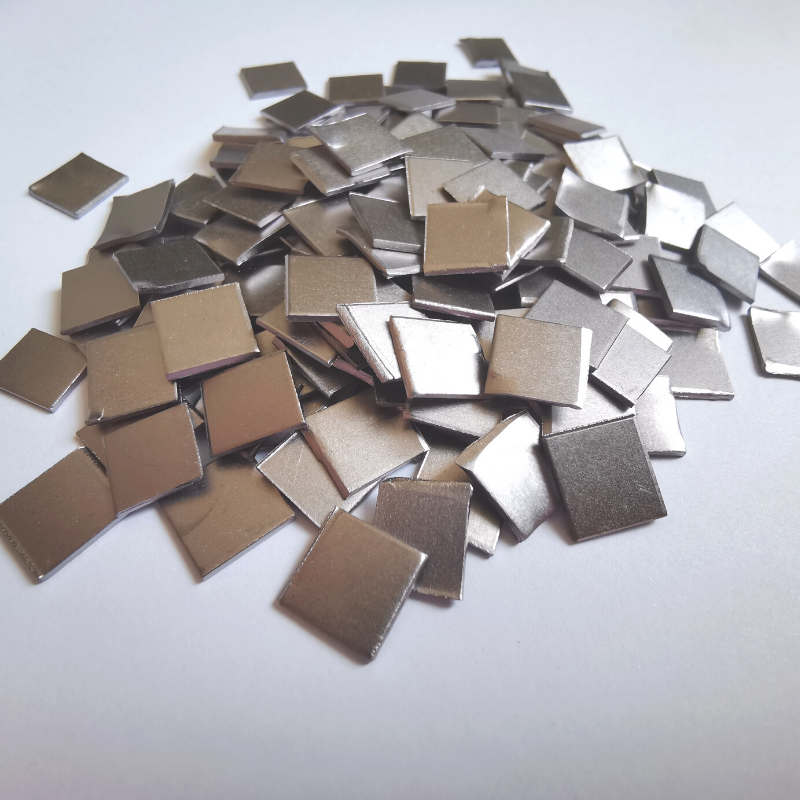

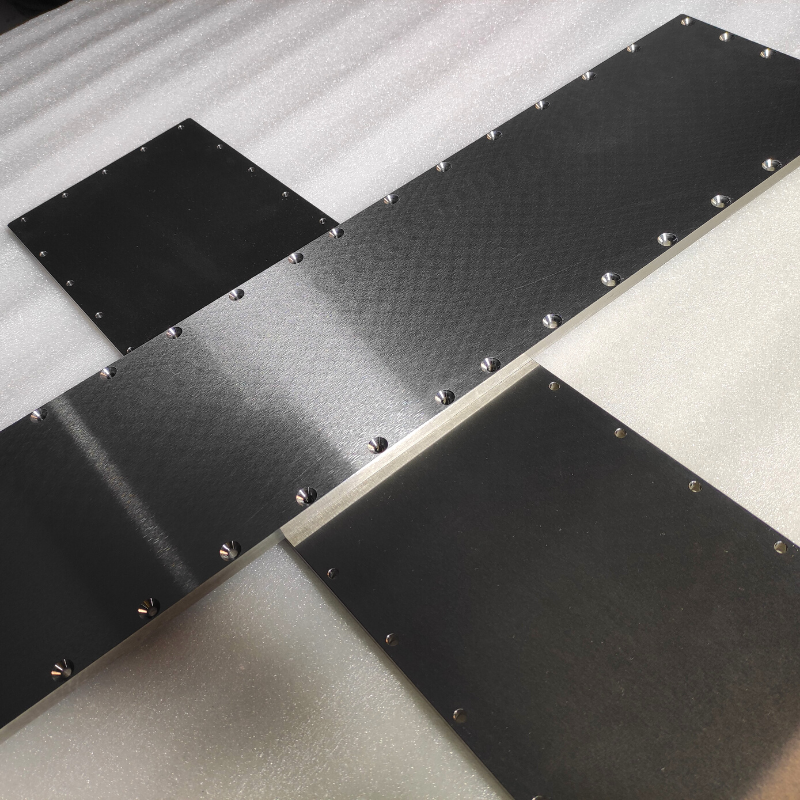

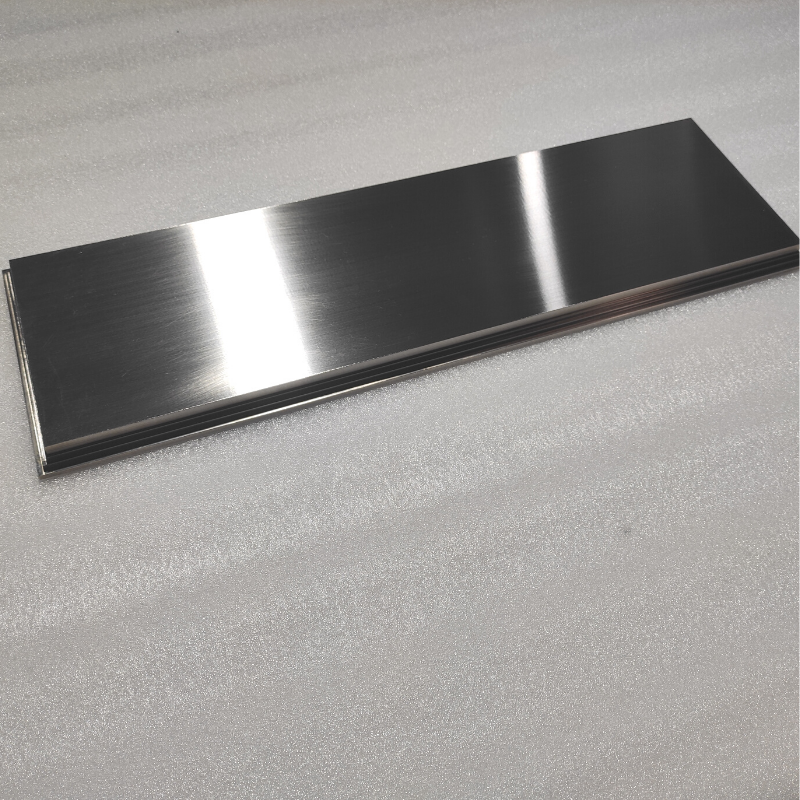

Product detail pictures:

Related Product Guide:

Adhering into the principle of "quality, provider, performance and growth", we now have gained trusts and praises from domestic and intercontinental consumer for Chinese Professional High Purity Material - CuMn Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich , The product will supply to all over the world, such as: Benin, Luxemburg, Greek, We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, please do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.