Welcome to our websites!

News

-

Analysis of the Three Core Preparation Processes for Sputtering Targets

The preparation process of sputtering targets directly affects their purity, density, microstructure, and final coating performance. The mainstream production methods currently include melting & casting, powder metallurgy, and spray forming, each with its own advantages and disadvantages, mak...Read more -

FeCoNiCrAl Sputtering Targets: Properties, Applications, and Future Prospects

Sputtering targets are core materials in physical vapor deposition (PVD) technology, widely used in semiconductors, display panels, solar cells, and other fields. Metals such as iron (Fe), cobalt (Co), nickel (Ni), chromium (Cr), and aluminum (Al), along with their alloy targets, play a crucial r...Read more -

Copper-Zinc Sputtering Target: A Cost-Effective “Gold-Like” Coating Solution

In the field of surface treatment, physical vapor deposition (PVD) technology has gained increasing popularity due to its environmental friendliness and efficiency. Among various sputtering targets, copper-zinc (Cu-Zn) targets stand out as a key material for decorative and functional coatings, of...Read more -

Nickel-Cobalt-Chromium Sputtering Targets: Properties, Fabrication, and Applications Review

Nickel-cobalt-chromium (Ni-Co-Cr) sputtering targets serve as crucial functional materials with extensive application value in thin-film deposition technologies. This paper systematically reviews the fundamental properties, fabrication processes, quality control methods, and current industrial ap...Read more -

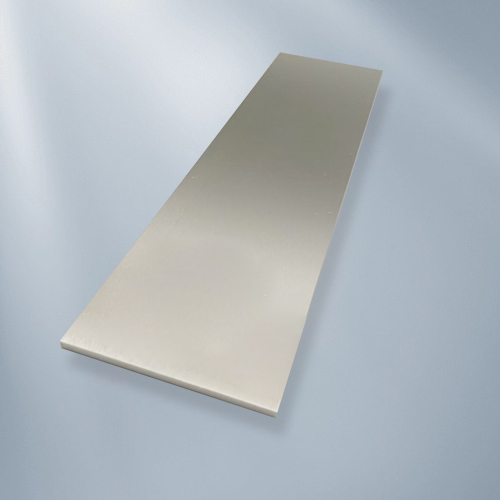

Why Does Alumina (Al₂O₃) Sputtering Target Require a Backing Plate?

In thin-film deposition processes, alumina (Al₂O₃) sputtering targets are widely used in semiconductors, optical coatings, and wear-resistant coatings due to their excellent insulation properties, high-temperature resistance, and chemical stability. However, as a ceramic material, alumina has poo...Read more -

Chromium Aluminum Sputtering Targets: Key Material Solution for Enhancing PVD Coating Performance

Chromium aluminum (CrAl) sputtering targets serve as critical raw materials in physical vapor deposition (PVD) processes, playing an irreplaceable role in the surface treatment of industrial tools and molds. These high-performance targets, through precise control of chromium and aluminum ratios c...Read more -

Chromium Sputtering Targets: The Key Material for High-Performance Thin Film Coatings

Chromium (Cr) sputtering targets are high-purity materials widely used in physical vapor deposition (PVD) technology to deposit high-performance chromium thin films on substrates. Chromium exhibits a silvery-white metallic luster, with high-purity chromium demonstrating good ductility, while chro...Read more -

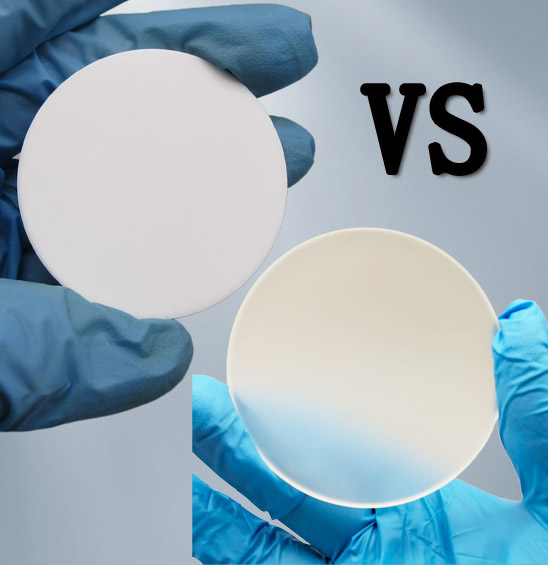

Silicon Dioxide (SiO₂) Sputtering Targets vs. Aluminum Oxide (Al₂O₃) Sputtering Targets

In the semiconductor, optical coating, and display industries, silicon dioxide (SiO₂) sputtering targets and aluminum oxide (Al₂O₃) sputtering targets are two of the most commonly used ceramic sputtering materials. However, their performance differences directly affect coating quality, cost, and ...Read more -

Industrial Iron vs. Non-Industrial Iron

Iron (Fe), one of the most important metals in human civilization, can be categorized into industrial iron and non-industrial iron based on its purity, production methods, and applications. These two types differ significantly in composition, properties, and usage. This article systematically...Read more -

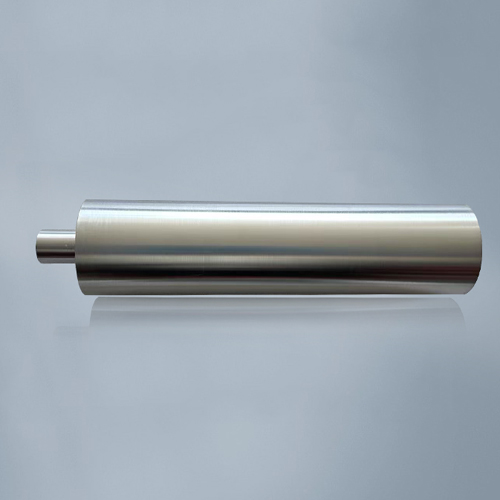

Metal Targets ——Pure Metal Targets: Characteristics, Fabrication, and Applications

Metal targets are core materials in thin-film deposition processes such as physical vapor deposition (PVD), magnetron sputtering, and electron beam evaporation, widely used in semiconductors, optics, photovoltaics, and tool coatings. Among them, pure metal targets (single-element targets) are par...Read more -

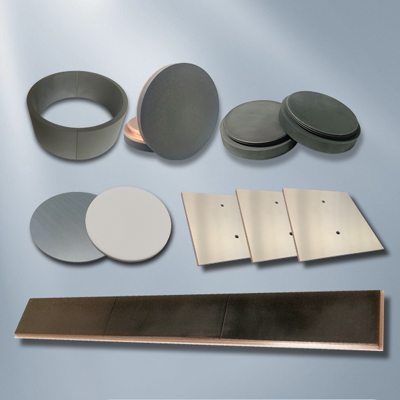

Ceramic Targets: A Comprehensive Review of Types, Fabrication, and Applications

Ceramic targets are key materials in thin film deposition techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD). They are widely used in semiconductors, optoelectronics, energy, and protective coatings due to their high melting points, superior hardness, excellent...Read more -

Comprehensive Analysis of Nickel-Based Special Alloys: Differences and Connections Among Hastelloy, Invar, Inconel, and Permalloy

Nickel-based alloys play a critical role in aerospace, chemical, electronics, energy, and other industries due to their unique physical, chemical, and mechanical properties. Special alloys such as Hastelloy, Invar, Inconel, and Permalloy each have distinct characteristics, making them suitable fo...Read more