Welcome to our websites!

News

-

Cobalt-Chromium-Iron-Nickel Alloy Target: The Future-Oriented High-Performance Coating Solution

In the field of materials science, Cobalt-Chromium-Iron-Nickel (CoCrFeNi) alloy targets are rapidly emerging as a highly promising advanced material for preparing high-entropy alloy (HEA) thin films. With their unique compositional design and groundbreaking comprehensive properties, they offer in...Read more -

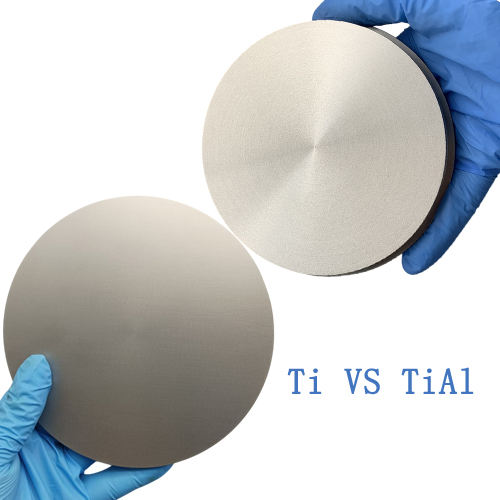

Comparison of Titanium Targets and Titanium Aluminum Targets: Properties, Coating Characteristics, and Applications

In Physical Vapor Deposition (PVD) and magnetron sputtering processes, the target material, as the source for thin-film deposition, directly determines the final coating’s performance. Titanium targets and titanium aluminum targets are two crucial materials widely used in semiconductors, de...Read more -

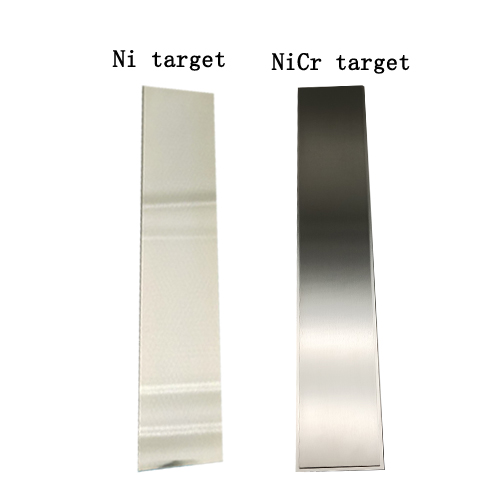

Comparison of Nickel Targets and Nickel-Chromium Targets: Properties, Coating Characteristics, and Applications

In the field of physical vapor deposition (PVD), nickel-based targets are indispensable key materials. Among them, pure nickel targets and nickel-chromium alloy targets occupy distinct application niches due to their unique properties. This article provides an in-depth comparison of the differenc...Read more -

The Process, Characteristics of Vacuum Induction Melted Nickel Alloy Ingots

Nickel-based alloys, as a critical component within the modern industrial materials system, play an indispensable role in aerospace, energy and chemical engineering, and high-end medical fields due to their exceptional high-temperature strength, superior corrosion resistance, and good fatigue per...Read more -

Vacuum Induction Melting (VIM) Alloy Ingots

Vacuum Induction Melting (VIM) is a key specialized metallurgical process for producing high-end metal materials. It involves heating, melting, refining, and finally casting metal into ingots within a sealed environment under high vacuum or inert gas protection, utilizing the principle of electro...Read more -

Sputtering Targets: The “Invisible Cornerstone” of Modern High-Tech Industries

Behind the brilliant screens of smartphones, the billions of transistors in computer chips, the thin heat-insulating films on car windows, and even the protective coatings on spacecraft surfaces lies a crucial foundational material—the sputtering target. Although not directly visible in the fina...Read more -

HEA Iron Titanium Copper Chromium Manganese alloy targets

In the fields of advanced manufacturing and new material R&D, the demand for high-performance thin films is rapidly growing. Traditional single-metal targets, such as pure copper or chromium targets, are struggling to meet increasingly complex application scenarios. At this point, an innovati...Read more -

Introduction to Copper-Nickel Alloy Bars

Here is a comprehensive introduction to copper-nickel alloy bars, covering their definition, common grades, core properties, main applications, and advantages. 1. What are Copper-Nickel Alloy Bars? Copper-nickel alloy bars, commonly known as ”cupronickel bars,” are wrought products (b...Read more -

Introduction to Iron-Nickel Alloys

Iron-nickel alloys are a family of precision alloys primarily composed of iron and nickel (with nickel content typically ranging from 30% to 90%), whose properties are fine-tuned by adding small amounts of other elements (such as molybdenum, copper, chromium, etc.). They are not ordinary steels b...Read more -

Stainless Steel: The Miracle of Not Rusting

Stainless steel is all around us, from kitchen sinks and utensils to the curtain walls of skyscrapers. While it may seem ordinary, it is actually a great invention in the history of human materials. Why is Stainless Steel “Stainless”? Its secret lies in the addition of a key element—c...Read more -

Sputtering Target Bonding with Backplate

In the semiconductor industry and electronic thin film preparation, the performance of sputtering targets directly determines the quality of deposited films, and the backing plate bonding technology behind the target is an indispensable key link in this process. During physical vapor deposition (...Read more -

Aluminum Chromium (AlCr) Sputtering Targets

Sputtering targets are the core materials in physical vapor deposition (PVD) technology. Through ion bombardment, target atoms are deposited onto substrates to form functional thin films. Among them, aluminum chromium alloy sputtering targets play an indispensable role in semiconductors, display ...Read more