Yintoni ii-alloy ye-zinc yobhedu (CuZn) i-sputtering target ?

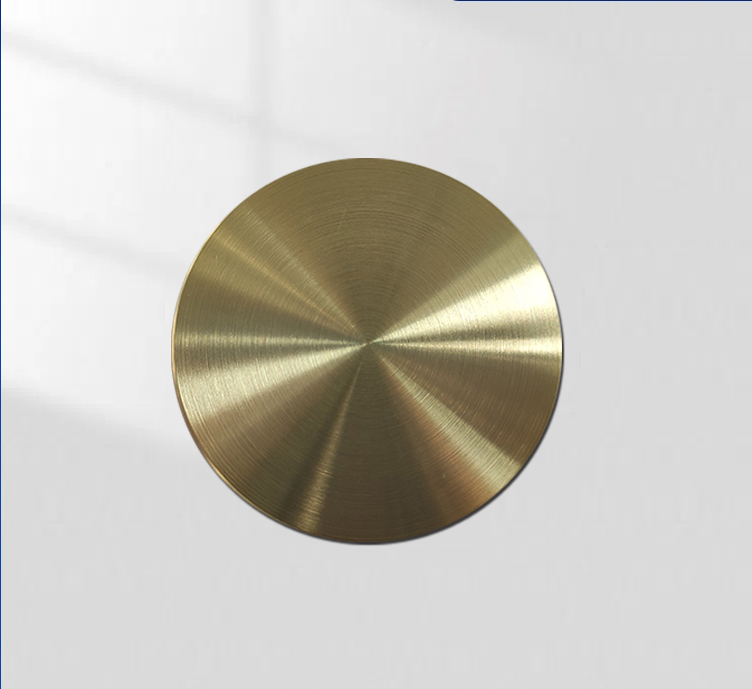

Ithagethi yokutshiza i-zinc yobhedu yinto ekujoliswe kuyo efunyenwe ngokunyibilikisa ubhedu obusulungekileyo obuphezulu kunye ne-zinc, ekwaziwa njengethagethi yokugalela ngobhedu. I-Copper Zinc Alloy Sputtering Target yimathiriyeli egqwesileyo yokutshiza kwishishini lokugquma ivacuum.

Ziziphi iingenelo zobhedu kunye neethagethi ze-zinc?

Iithagethi zeCopper kunye ne-zinc zizuza njengelifa ezinye iimpawu ezibalaseleyo zobhedu, ezifana ne-conductivity egqwesileyo yombane kunye ne-thermal conductivity ephezulu. I-conductivity ephezulu yenza iithagethi zobhedu kunye ne-zinc zidlala indima ephambili ekuveliseni iindlela zokuqhuba kwizixhobo zombane, ngelixa ukuhanjiswa kwe-thermal ephezulu kunceda ukudlulisa ngokufanelekileyo ukushisa ngexesha lokusetyenziswa, ukunciphisa ukuveliswa kweendawo ezishushu, kunye nokuphucula ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso.

Ithagethi ye-Copper-zinc inombono obanzi wokusetyenziswa kwiinkalo ezininzi ngenxa yeenzuzo zayo zokucoceka okuphezulu, ukufana okuhle, ukulungiswa okulula, ukuguqulwa okuphezulu kunye nokulungelelanisa.

Ziziphi iimeko zokusetyenziswa kweethagethi zobhedu kunye ne-zinc?

I-1.Imboni ye-Electronics: Iithagethi ze-Copper kunye ne-zinc zithatha indawo ebalulekileyo kwishishini lombane. Xa ulungiselela iifilimu ezincinci, zingasetyenziselwa i-transistor metallization, i-capacitor electrode, njl. Ezi zicelo zibaluleke kakhulu kumgangatho weesekethe ezidibeneyo kunye nokuveliswa kwefilimu encinci. Ngoko ke, umgangatho wobhedu kunye ne-zinc target ichaphazela ngokuthe ngqo ukusebenza kunye nokuthembeka kwemveliso yokugqibela ye-elektroniki.

I-2.Izixhobo zokugqoka: Iithagethi ze-Copper kunye ne-zinc nazo zisetyenziswa ngokubanzi kwintsimi yezinto zokugubungela. Ukucoceka kwayo okuphezulu kunye nokufana kwenza kube yinto efanelekileyo yokulungiselela iingubo eziphezulu. Nokuba kwiimbumba zetsimbi, ubushushu obuphezulu bezinto ezixhathisayo kwi-corrosion okanye iimveliso zokuhombisa eziphezulu, iithagethi zobhedu kunye ne-zinc zinokudlala umsebenzi ogqwesileyo.

Iiseli ze-3.olar: Ngophuhliso olukhawulezayo lwamandla avuselelekayo, imfuno yeethagethi zethusi kunye ne-zinc kwintsimi yeeseli zelanga nazo zanda. Iithagethi ze-Copper kunye ne-zinc zidlala indima ephambili kwinkqubo yokwenziwa kweeseli zelanga, inceda ukuphucula ukuguqulwa kwe-photoelectric ukusebenza kakuhle kunye nobomi benkonzo yeeseli.

Izicelo ze-4.ther: Ukongezelela, iithagethi zethusi kunye ne-zinc nazo zisetyenziselwa imboni yokugcina ulwazi, njenge-hard disk, intloko yamagnetic, i-optical disc kunye nezinye iimveliso. Ngexesha elifanayo, kwishishini lokubonisa i-flat, iithagethi zethusi kunye ne-zinc nazo zisetyenziswa ngokubanzi ekwenzeni i-crystal display display (LCD) kunye ne-plasma display (PDP) iimveliso.

Iyintoni inkqubo yokuvelisa iithagethi zethusi kunye ne-zinc?

1.Ukulungiswa kwemathiriyeli ekrwada: Okokuqala, khetha ubhedu obusulungekileyo obuphezulu kunye ne-zinc njengemathiriyeli ekrwada. Ezi zinto zikrwada zivavanywa ngokungqongqo kwaye zivavanywa ukuqinisekisa ukuba umgangatho wazo kunye nokusulungeka kwazo ziyahlangabezana neemfuno zemveliso.

2.I-Melting kunye ne-alloying: Ubhedu olulungisiweyo kunye ne-zinc izinto eziluhlaza zifakwa kwisithando somlilo esinyibilikayo ngomlinganiselo othile wokunyibilika. Kwinkqubo ye-smelting, ngokulawula ukushisa kunye nexesha, ubhedu kunye ne-zinc zixutywe ngokupheleleyo kwaye zifikelele kwisimo esifanayo ukwenza i-alloy ye-copper-zinc.

3.Ukuphosa kunye nokubumba: I-alloy yobhedu kunye ne-zinc alloy igalelwe kwi-mold for casting and molding. Eli nyathelo lifuna ulawulo oluchanekileyo lwesantya sokuphosa kunye nobushushu bokuqinisekisa ubume obufunwayo kunye nobukhulu bethagethi.

I-4.Ukucutshungulwa kunye nokunyangwa kokushisa: ukucubungula kunye nokuphathwa kokushisa kweethagethi zethusi kunye ne-zinc. Oku kubandakanya ukusika, ukugaya, ukupholisa kunye nezinye iinkqubo zokususa ukungcola kwendawo kunye neziphene kunye nokuphucula ukugqiba kunye nokunyuka kwethagethi. Ngexesha elifanayo, i-microstructure kunye neepropati ekujoliswe kuzo zingaphuculwa ngakumbi ngonyango lokushisa.

Ukuhlolwa komgangatho kunye nokulawula: Kuyo yonke inkqubo yokuvelisa, iithagethi zethusi kunye ne-zinc zihlolwe ngokungqongqo kwaye zilawulwa. Oku kubandakanya uhlalutyo lokuqulunqa, uvavanyo loxinaniso, uvavanyo lokuqina, njl., Ukuqinisekisa ukuba umgangatho kunye nokusebenza kokujoliswe kuko kuhlangabezana nemigangatho yokuvelisa.

5.Ukucoca kunye nokupakisha.

Ixesha lokuposa: Apr-25-2024