What is copper zinc alloy(CuZn) sputtering target ?

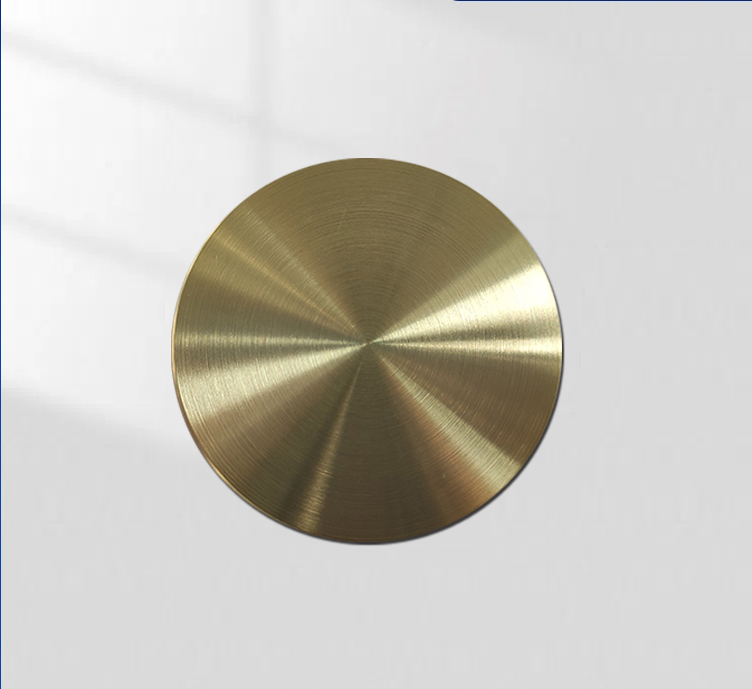

Copper zinc sputtering target is a target obtained by smelting high purity copper and zinc, also known as brass sputtering target. Copper Zinc Alloy Sputtering Target is Excellent sputtering materials in vacuum coating industry.

What are the advantages of copper and zinc targets?

Copper and zinc targets inherit some excellent characteristics of copper, such as excellent electrical conductivity and high thermal conductivity. High conductivity makes copper and zinc targets play a key role in manufacturing conductive paths in electronic devices, while high thermal conductivity helps to effectively transfer heat during use, reduce the generation of hot spots, and improve production efficiency and product quality.

Copper-zinc target has a wide application prospect in many fields due to its advantages of high purity, good uniformity, easy preparation, high conversion efficiency and adjustability.

What are the application scenarios of copper and zinc targets?

1.Electronics industry: Copper and zinc targets occupy an important position in the electronics industry. When preparing thin films, it can be used for transistor metallization, capacitor electrodes, etc. These applications are critical for the quality of integrated circuits and thin film production. Therefore, the quality of the copper and zinc target directly affects the performance and reliability of the final electronic product.

2.Coating materials: Copper and zinc targets are also widely used in the field of coating materials. Its high purity and uniformity make it ideal for preparing high-quality coatings. Whether in metal composites, high temperature corrosion resistant materials or high-end decorative products, copper and zinc targets can play an excellent performance.

3.olar cells: With the rapid development of renewable energy, the demand for copper and zinc targets in the field of solar cells is also increasing. Copper and zinc targets play a key role in the manufacturing process of solar cells, helping to improve the photoelectric conversion efficiency and service life of the cells.

4.ther applications: In addition, copper and zinc targets are also used in the information storage industry, such as hard disk, magnetic head, optical disc and other products. At the same time, in the flat display industry, copper and zinc targets are also widely used in the manufacture of liquid crystal display (LCD) and plasma display (PDP) products.

What is the production process of copper and zinc targets?

1.Raw material preparation: First, select high purity copper and zinc as raw materials. These raw materials undergo rigorous screening and testing to ensure that their quality and purity meet production requirements.

2.Melting and alloying: The prepared copper and zinc raw materials are put into the melting furnace in a certain proportion for melting. In the smelting process, by controlling the temperature and time, the copper and zinc are fully mixed and reach a uniform state to form a copper-zinc alloy.

3.Casting and molding: The melted copper and zinc alloy is poured into the mold for casting and molding. This step requires precise control of the casting speed and temperature to ensure the desired shape and size of the target.

4.Processing and heat treatment: processing and heat treatment of cast copper and zinc targets. This includes cutting, grinding, polishing and other processes to remove surface impurities and defects and improve the finish and flatness of the target. At the same time, the microstructure and properties of the target can be further improved by heat treatment.

Quality inspection and control: In the entire production process, the copper and zinc targets are strictly inspected and controlled. This includes composition analysis, density testing, hardness testing, etc., to ensure that the quality and performance of the target meets production standards.

5.Cleaning and packing.

Post time: Apr-25-2024