Welcome to our websites!

News

-

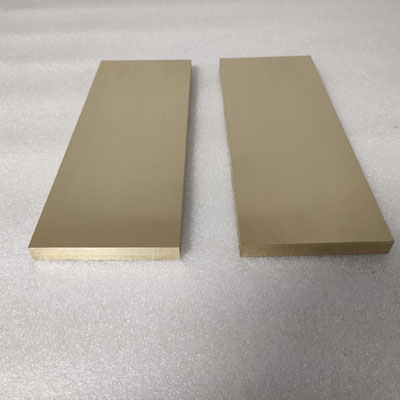

Aluminum Chromium (AlCr) Sputtering Targets

Sputtering targets are the core materials in physical vapor deposition (PVD) technology. Through ion bombardment, target atoms are deposited onto substrates to form functional thin films. Among them, aluminum chromium alloy sputtering targets play an indispensable role in semiconductors, display ...Read more -

Copper Zinc Tin Alloy Sputtering Target

In the pursuit of green energy and cutting-edge electronic technology, there is a fundamental material that, while inconspicuous, is crucial: the sputtering target. Imagine this: inside a high-vacuum chamber, a solid material is bombarded by high-energy particles, causing its atoms to fly off lik...Read more -

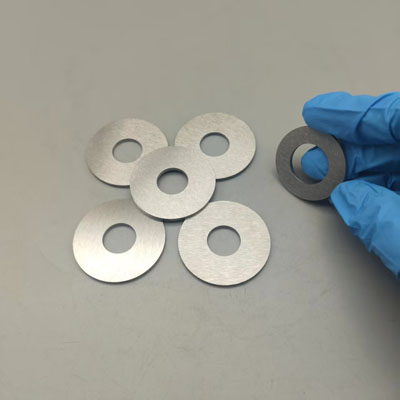

Manganese Copper M2052 Damping Alloy Gasket

Manganese Copper M2052 Damping alloy is a specialized high-damping functional material used for vibration and noise reduction. It is not an ordinary support gasket, but rather a structural-functional integrated component that effectively converts mechanical vibration energy into thermal energy. T...Read more -

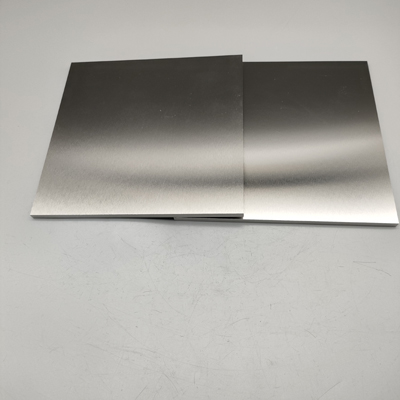

Iron-Copper Alloy Sputtering Target

Today, with the rapid development of semiconductor and display technologies, sputtering targets, as the core materials in thin film deposition processes, directly determine the quality of the final product. Among them, the iron-copper alloy sputtering target, with its unique performance advantage...Read more -

Manganese-Cobalt Alloy Target

Manganese-Cobalt Alloy Target is an advanced functional material synthesized from cobalt and manganese in specific proportions, used to form functional thin films on substrates through physical vapor deposition technology. It perfectly combines cobalt’s high magnetic properties and excellen...Read more -

Chromium Diboride Sputtering Target

As the performance requirements for mechanical components in modern industry continuously increase, traditional coating materials are increasingly revealing their limitations. The chromium diboride sputtering target, as an emerging advanced coating material, is becoming a key solution to material...Read more -

A Comprehensive Analysis of Nickel-Cobalt Alloy Sputtering Targets

What Are Nickel-Cobalt Alloy Sputtering Targets, and Why Are They So Important? Nickel-cobalt alloy sputtering targets are critical materials used in physical vapor deposition (PVD) processes, primarily composed of nickel and cobalt in specific ratios. These materials play an indispensable role ...Read more -

A Comprehensive Analysis of Nickel-Cobalt-Iron-Aluminum-Chromium-Titanium Alloy Sputtering Targets

In today’s rapidly advancing fields of advanced manufacturing and materials science, sputtering targets, as core materials for surface engineering and thin-film preparation, are playing an increasingly vital role. Among them, nickel-cobalt-iron-aluminum-chromium-titanium (Ni-Co...Read more -

Comprehensive Analysis of Iron-Nickel-Chromium Sputtering Targets

An iron-nickel-chromium sputtering target (Fe-Ni-Cr Sputtering Target) is a high-purity alloy material used in physical vapor deposition (PVD), composed of iron (Fe), nickel (Ni), and chromium (Cr) in specific ratios. For example, in the semiconductor industry, iron-nickel-chromium sputtering tar...Read more -

AZO vs ITO Sputtering Targets: Properties, Applications, and Future Complementary Landscape

Transparent conductive oxide (TCO) sputtering targets are critical materials in optoelectronic applications, with AZO (aluminum-doped zinc oxide) and ITO (indium tin oxide) being the two dominant options. Due to differences in performance, cost, and resource availability, these materials have for...Read more -

Process Principles and Applications of Sputtering Targets

Sputtering targets are key materials in Physical Vapor Deposition (PVD) technology, widely used in semiconductors, display panels, optical coatings, hard coatings, and other fields. Their process principle is based on the bombardment of the target surface by high-energy particles, causing atoms o...Read more -

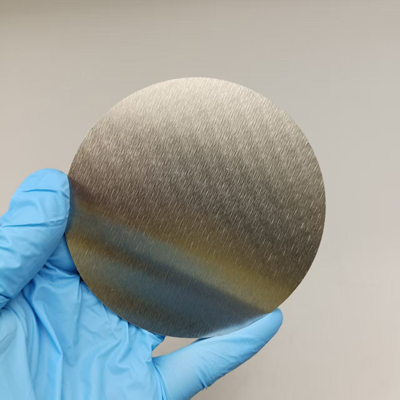

Titanium Sputtering Targets: Applications, Advantages Comprehensive Analysis

Titanium sputtering targets are critical materials in physical vapor deposition (PVD) technology, widely used in semiconductors, tool coatings, optical films, and biomedical applications. This article provides an in-depth analysis of titanium targets, covering their properties, applications, manu...Read more