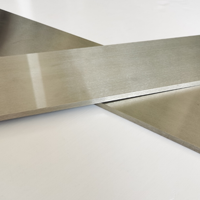

Before, many customers asked colleagues from RSM Technology Department about titanium alloy. Now, I would like to summarize the following points for you about what metal titanium alloy is made of. I hope they can help you.

Titanium alloy is an alloy made of titanium and other elements.

Titanium is a homogeneous heterogeneous crystal, with a melting point of 1720 ℃. When the temperature is lower than 882 ℃, it has a closely packed hexagonal lattice structure, which is called α Titanium; It has a body centered cubic structure above 882 ℃, which is called β Titanium. Taking advantage of the different characteristics of the above two structures of titanium, appropriate alloy elements are added to gradually change its phase transformation temperature and phase content to obtain titanium alloys with different structures. At room temperature, titanium alloys have three kinds of matrix structures, and titanium alloys are also divided into the following three categories: α Alloy( α+β) Alloy and β Alloy. In China, it is indicated by TA, TC and TB respectively.

α titanium alloy

It is α Single phase alloy composed of phase solid solution is α Phase, stable structure, higher wear resistance than pure titanium, strong oxidation resistance. Under the temperature of 500 ℃~600 ℃, it still maintains its strength and creep resistance, but cannot be strengthened by heat treatment, and its room temperature strength is not high.

β titanium alloy

It is β The single-phase alloy composed of phase solid solution has higher strength without heat treatment. After quenching and aging, the alloy is further strengthened, and the room temperature strength can reach 1372 ~ 1666 MPa; However, the thermal stability is poor and it is not suitable for use at high temperatures.

α+β titanium alloy

It is a dual phase alloy with good comprehensive properties, good structural stability, good toughness, plasticity and high-temperature deformation properties. It can be used for hot pressure processing, quenching and aging to strengthen the alloy. The strength after heat treatment is about 50%~100% higher than that after annealing; High temperature strength, can work at 400 ℃~500 ℃ for a long time, and its thermal stability is less than α Titanium alloy.

Among the three titanium alloys α Titanium alloys and α+β Titanium alloy; α Titanium alloy has the best machinability, α+ P Titanium alloy takes the second place, β Titanium alloy is poor. α The code of titanium alloy is TA, β The code of titanium alloy is TB, α+β The code of titanium alloy is TC.

Titanium alloys can be divided into heat-resistant alloys, high-strength alloys, corrosion resistant alloys (titanium molybdenum, titanium palladium alloys, etc.), low-temperature alloys and special functional alloys (titanium iron hydrogen storage materials and titanium nickel memory alloys) according to their applications.

Heat treatment: titanium alloy can obtain different phase composition and structure by adjusting the heat treatment process. It is generally believed that fine equiaxed microstructure has good plasticity, thermal stability and fatigue strength; The acicular structure has high rupture strength, creep strength and fracture toughness; Mixed equiaxed and acicular tissues have better comprehensive functions

Post time: Oct-26-2022