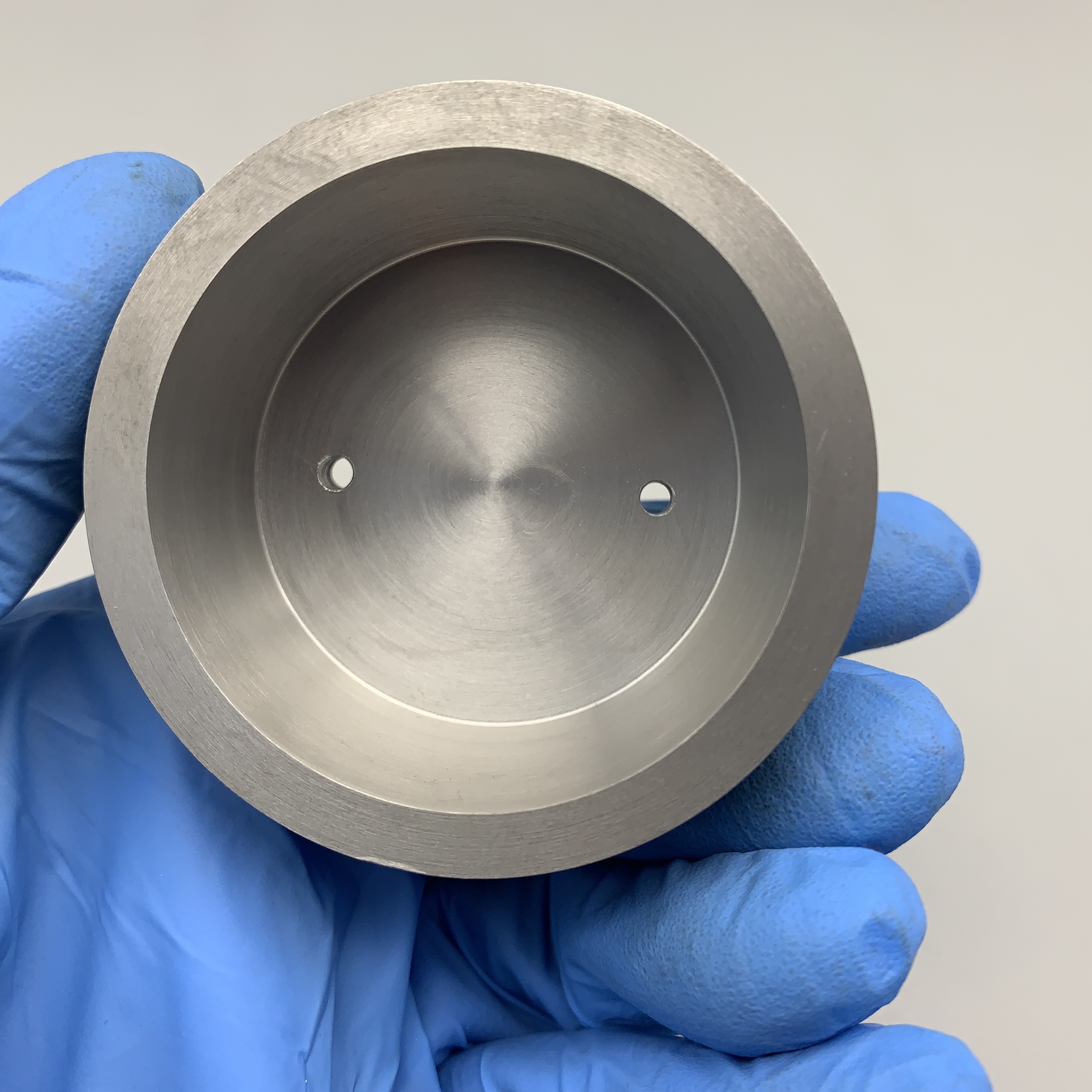

Molybdenum crucibles are mainly used in industries such as metallurgy, rare earth, monocrystalline silicon, artificial crystals, and mechanical processing. Due to the high melting point of molybdenum reaching 2610 ℃, molybdenum crucibles are widely used as core containers in industrial furnaces such as sapphire single crystal growth furnaces, quartz glass melting furnaces, rare earth smelting furnaces, etc. Their working temperature environment is generally above 2000 ℃.

Molybdenum crucibles have relatively high strength, and their matrix strength can be strengthened through a certain degree of cold processing. Some branded crucibles can also be strengthened through heat treatment. It also has advantages such as good conductivity, low density, and simple processing. The crucible is made of FMo-1 molybdenum powder, with a product density greater than 9.8g/cm3 and a usage temperature of 1100 ℃.

Physical and chemical properties:

1. Purity: W ≥ 99.95%;

2. Density: ≥ 9.8g/cm3;

3. Application temperature environment: 2400 ℃.

In addition, molybdenum crucibles are more commonly used in various formed products because they are affected by the processing technology during processing and use. Additionally, their thin thickness can affect their service life if used improperly.

Post time: Jan-05-2024