The Material Challenges Behind Sputtering Technology Advancements

As semiconductor manufacturing enters the 3nm process era, traditional copper-nickel targets reveal growing limitations. A 2023 Global Market Insights report shows the global sputtering target market has reached

6.5billion,yetthesupplygapforhigh−endzinc−manganese(Zn−Mn)targetsstillexceeds3010 million in losses.

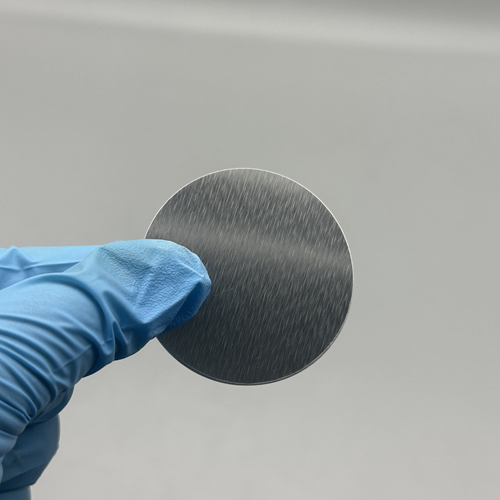

Counterintuitively, adjusting alloy ratios—seemingly straightforward—involves complex crystal structure reorganization. During conventional sputtering, zinc tends to oxidize into amorphous layers, while manganese’s magnetic properties disrupt deposition uniformity. Achieving precise 1:1.5 atomic ratio control has become the key to overcoming technical barriers.

Decoding the Performance Advantages of Zn-Mn Targets

Comparative Analysis Table

| Property | Zn-Mn Targets | Cu-Ni Targets | Al-Based Targets |

|---|---|---|---|

| Resistivity (μΩ·cm) | 4.2 | 1.7 | 2.8 |

| Thermal Expansion (×10⁻⁶/K) | 13.1 | 16.5 | 23.6 |

| Deposition Rate (nm/min) | 85 | 120 | 65 |

| Service Life (hours) | 350 | 280 | 400 |

Magnetron sputtering experiments confirm Zn-Mn alloy films exhibit unique gradient conductivity. For example, in flexible display applications, their adjustable stress range (0.8–2.1 GPa) perfectly adapts to substrates with varying curvature. U.S. Department of Energy data indicates Zn-Mn targets improve OLED device efficiency by 22% (Source: DOE 2024 Annual Report).

Five Breakthrough Pathways for Mass Production

- Alloy Ratio Optimization: Apply gradient sintering to achieve Zn = 52:48

- Purity Control: Use vacuum plasma refining to reduce impurities below 10 ppm

- Grain Orientation: Magnetic alignment for 50–80 nm grain sizes

- Interface Strengthening: Nano-scale titanium interlayers enhance target-backplate bonding

- Smart Monitoring: AIoT systems track sputtering power fluctuations in real-time

⚠ Warning: Never arbitrarily increase annealing temperatures above 800°C! This triggers abnormal manganese segregation, forming hazardous β-phase intermetallic compounds.

Real-World Application Case Studies

In photovoltaics, a TopCon cell manufacturer using our Zn-Mn targets reduced electrode contact resistance to 0.8 mΩ·cm². By adjusting the sputtering angle to 55° and dynamic pressure to 0.3 Pa, film thickness variation was controlled within ±1.2 nm.

Interestingly, Zn-Mn alloys excel in MEMS applications. Their stress self-compensation effect slashed gyroscope thermal drift errors by 40%, a phenomenon rooted in manganese’s spin-orbit coupling effects creating quantum well structures.

Future Trends and Opportunities

As atomic layer deposition (ALD) gains traction, Zn-Mn target nanostructuring faces new opportunities. However, the EU’s updated RoHS regulations on heavy metals are pushing firms to develop cadmium-free stabilizers. Collaborating with the Chinese Academy of Sciences, we’re developing magneto-electric coupled targets projected to boost sputtering efficiency by 30%.

Implementation Checklist

1.Validate ICP-MS test reports for target certificatio

2.Calibrate sputtering chamber vacuum to 5×10⁻⁶ Pa

3.Program gradient heating (20°C/min to 650°C)

4.Set Ar/O₂ gas mix ratio (92:8)

5.Execute pre-sputtering cleaning (≥30 minutes)

Through optimized material genomics and process parameters, Zn-Mn targets are reshaping the sputtering industry. As one expert noted: “Mastering quantum-level control of Zn-Mn alloys unlocks the next era of electronics beyond Moore’s Law.

Post time: Mar-25-2025