Modern buildings began to use large areas of glass lighting. This aspect gives us brighter rooms and wider horizons. On the other hand, the heat transmitted through the glass is much higher than the surrounding walls, and the energy consumption of the whole building increases significantly.

Compared with the utilization rate of more than 90% of low-radiation glass in developed countries, the penetration rate of low-E glass in China is only about 12%, and China still has a lot of space for development.However, compared with ordinary glass and online low-E glass, the production cost of offline LowE glass is high, which restricts the application of a certain degree.Domestic glass processing enterprises have the obligation to continuously reduce the production cost of coating products, speed up the implementation, save energy, improve the environment, and achieve social sustainable development.

1、Influence of target shape

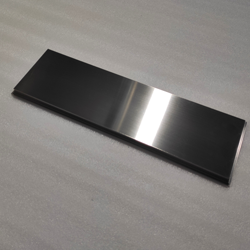

Large areas of coating often use target material according to shape, including planar orientation and rotational orientation. General planar targets include copper target, silver target, Ni-Cr target and graphite target. The general rotating target has zinc aluminum target, zinc tin target, silicon aluminum target, tin target, titanium oxide target, zinc oxide aluminum target and so on.The target shape will affect the stability and film properties of magnetron sputtering coating, and the utilization rate of target is very high. After changing the shape planning of target, the quality and production power of coating can be improved and the cost can be saved.

2、Influence of relative density and clearance of target

The relative density in the target is the ratio of the practical density to the theoretical density of the target, the theoretical density of the single component target is the crystal density, and the theoretical density of the alloy or mixture target is calculated according to the theoretical density of each element and the proportion in the alloy or mixture.. The target arrangement of the thermal sprayer is porous, highly oxygenated (even with vacuum spray, the production of oxides and nitrous compounds in the alloy target is inevitable), and the appearance is gray and lacks metallic luster. Adsorbed impurities and moisture are the primary sources of pollution.

3、Influence of target particle size and crystal direction

In the same weight of target, the target with small particle size is faster than the target with large particle size. This is primarily because the particle boundary in the process of splashing is easy to be invaded, the more the particle boundary, the faster the film formation. The particle size not only affects the sputtering speed, but also affects the quality of film formation.For example, in the production process of EowE products, NCr acts as the maintenance layer of infrared reflective layer Ag, and its quality has a great influence on coating products. Due to the large extinction coefficient of NiCr film layer, it is generally thin (about 3nm).If the particle size is too large, the sputtering time becomes shorter, the densification of the film layer becomes worse, the maintenance effect of the Ag layer decreases, and the oxidation decoating of the coating products is brought about.

conclusion

The shape planning of target material mainly affects the utilization rate of target material. Reasonable size planning can improve the utilization rate of target material and save the cost.The smaller the particle size, the faster the coating speed, the better the uniformity. The higher the purity and density, the lower the porosity, the better the film quality, and the lower the probability of discharge slag reduction.

Post time: Apr-27-2022