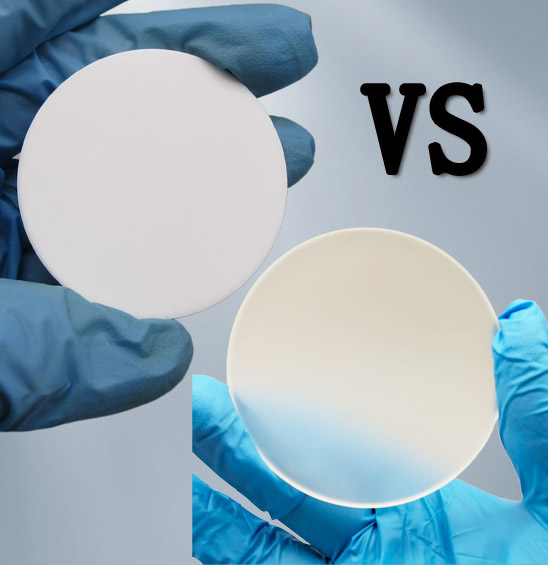

In the semiconductor, optical coating, and display industries, silicon dioxide (SiO₂) sputtering targets and aluminum oxide (Al₂O₃) sputtering targets are two of the most commonly used ceramic sputtering materials. However, their performance differences directly affect coating quality, cost, and suitability for specific applications.

Common questions:

1. Which target is better for high-precision optical coatings?

2.Which is more suitable for high-temperature electronic devices?

3. What are the cost differences?

This article will compare material properties, applications, and cost factors to help you make the best choice.

Material Properties Comparison (Key Parameters)

| Property | Silicon Dioxide (SiO₂) Target | Aluminum Oxide (Al₂O₃) Target |

|---|---|---|

| Purity | 99.99% (4N grade) | 99.95% (3N5 grade) |

| Density | 2.2 g/cm³ | 3.95 g/cm³ |

| Melting Point | 1713°C | 2072°C |

| Hardness (Mohs Scale) | about 6 | about 9 (close to sapphire) |

Key Takeaways:

Al₂O₃ is more heat-resistant and harder, making it ideal for wear-resistant coatings.

SiO₂ has a lower dielectric constant, making it better for semiconductor insulation layers.

Application Comparison: Which sputtering Target Fits Your Needs?

(1) Semiconductor Industry

SiO₂ Targets: Used for gate dielectric layers (low dielectric loss). Suitable for CMOS, DRAM, and other logic chips.

Al₂O₃ Targets: Used for passivation layers (high chemical resistance). Ideal for power devices (GaN, SiC).

Recommendation:

Need low dielectric loss? → Choose SiO₂

Need high corrosion resistance? → Choose Al₂O₃

(2) Optical Coatings

SiO₂ Targets:Used for anti-reflective (AR) coatings (refractive index: 1.46). Ideal for camera lenses, laser optics.

Al₂O₃ Targets:Used for scratch-resistant protective layers (high hardness). Suitable for smartphone screens, watch glass.

Recommendation:

Need high light transmittance? → Choose SiO₂ Need scratch resistance? → Choose Al₂O₃

(3) Display Industry (OLED, MicroLED) SiO₂ Targets: Used for encapsulation layers (excellent moisture/oxygen barrier). Al₂O₃ Targets: Used for TFT insulation layers (high dielectric constant).

Recommendation:

Need flexible encapsulation? → Choose SiO₂

Need high dielectric performance? → Choose Al₂O₃

Cost Comparison: Which is More Economical?

Al₂O₃ targets are cheaper, but sputtering rates are slower.

SiO₂ targets last longer, making them better for high-precision coatings.

Common Misconceptions & Selection Tips

Myth 1: “Al₂O₃ can completely replace SiO₂ targets.”

Fact: Al₂O₃ has a high dielectric constant, making it unsuitable for high-frequency chips (e.g., 5G RF devices). SiO₂ has a lower thermal expansion coefficient, matching silicon wafers better.

Myth 2: “SiO₂ targets can’t withstand high temperatures.”

Fact: Although its melting point is lower than Al₂O₃, it remains stable below 1700°C, sufficient for most applications.

Final Selection Guide

| Your Requirement | Recommended Target |

|---|---|

| Low dielectric loss (semiconductors) | SiO₂ |

| High wear resistance (optical glass) | Al₂O₃ |

| Low cost (industrial coatings) | Al₂O₃ |

| High purity (electronic-grade) | SiO₂ |

Conclusion: How to Choose the Best Sputtering Target?

Choose SiO₂ if you need: Low dielectric loss, high optical transparency, flexible encapsulation.

Choose Al₂O₃ if you need:High hardness, heat resistance, chemical corrosion resistance.

Final Recommendation: Consider application requirements + budget, and consult target suppliers for customized solutions if needed.

Post time: Sep-10-2025