Performance Characteristics of Nickel – Iron – Vanadium Alloy

1 The sputttering target with high Purity: The purity of raw materials is usually required to be greater than 99.99%. This can effectively reduce the introduction of impurities, ensuring that the deposited thin films during the sputtering process possess excellent properties, such as high electrical conductivity and high magnetic properties.

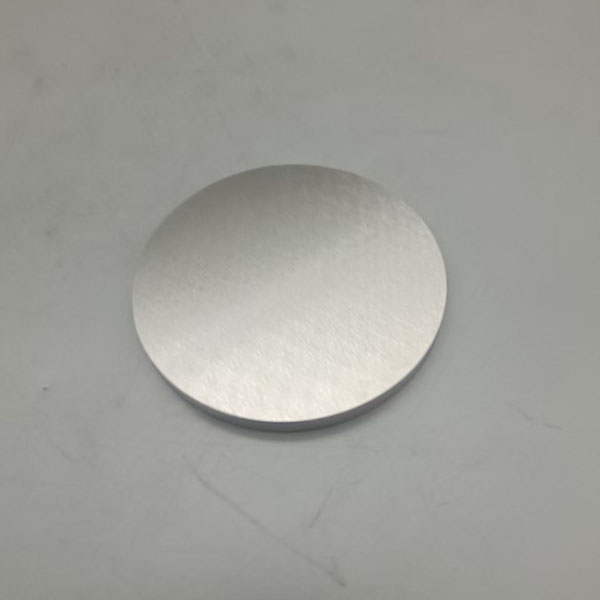

2.The nickel alloy metal sputtering target has good mechanical properties: It has relatively high strength and hardness. This enables the target to withstand certain impact forces and frictional forces during use, making it less likely to deform or be damaged. Meanwhile, it also has a certain degree of toughness and ductility, facilitating processing into various shapes and sizes to meet the requirements of different application scenarios.

3.The nifev functional film target material with excellent magnetic properties: Both nickel and iron are magnetic metal elements. The addition of vanadium can further adjust the magnetism of the alloy, enabling it to exhibit a high magnetic permeability even in a weak magnetic field. It can be used to prepare thin – film materials with special magnetic property requirements.

4.The sputtering target coating material with good Thermal Stability: The alloy has a high melting point and thermal conductivity. During the high – temperature sputtering process, it can maintain stable performance and is less prone to phenomena such as deformation, melting, or evaporation.

5.Magnetron sputtering NiFeV target with excellent Corrosion Resistance: The addition of vanadium significantly enhances the corrosion resistance of the alloy.

Nickel – iron – vanadium alloy targets have a wide range of applications. In the electronic information field, they are used in hard disk storage and chip manufacturing. In the flat – panel display field, they help prepare electrodes for TFT arrays and transparent conductive films. In the solar cell field, they can be used as electrodes and back – contact layers. In the sensor field, they can be used to fabricate key components of magnetic sensors and pressure sensors.

Post time: Feb-13-2025