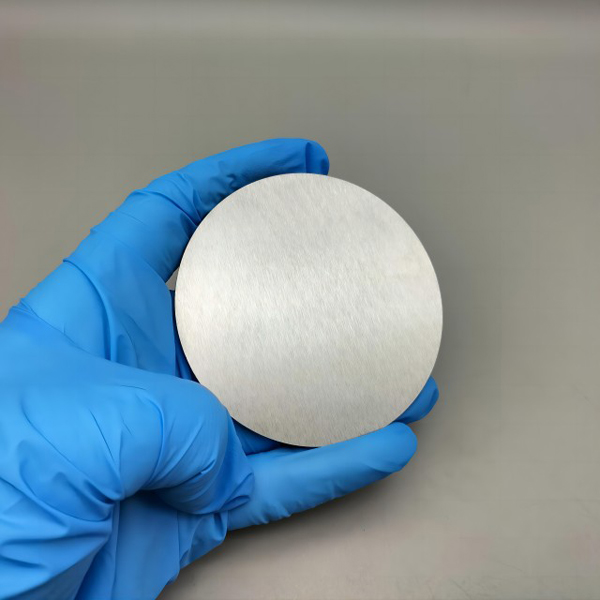

Sputtering targets can be divided into metal targets, alloy targets, and ceramic targets according to the material. today,Today, i will take you to understand the metal target.

Metal targets are vital materials in modern industry and are widely used in many fields. Metal target is usually used as a source material in physical vapor deposition (PVD) technology, and various functional films are deposited on the substrate by sputtering and other processes.

Common metal targets are aluminum targets, copper targets, Titanium targets,Cobalt target, iron targets, chromium target, nickel targets, Gold target, tin targets, platinum targets, Germanium targets, gallium targets, tungsten targets, tantalum targets, niobium targets, vanadium targets, bismuth targets, Iridium targets, carbon targets, silicon targets and so on.

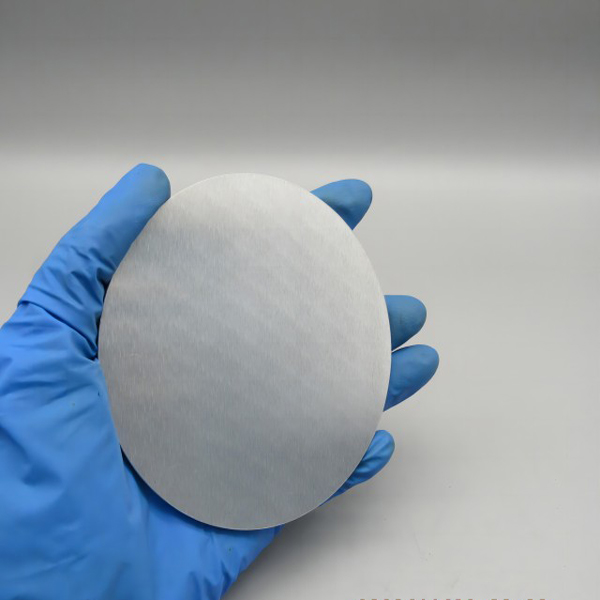

Aluminum (Al) sputtering target material with a good conductivity and reflection, used in semiconductor and optical fields.

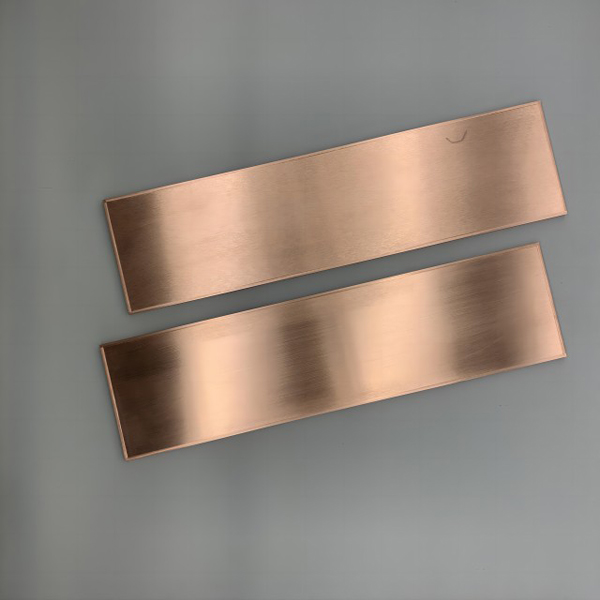

Copper (Cu) pvd target material with excellent electrical conductivity, used in printed circuit boards.

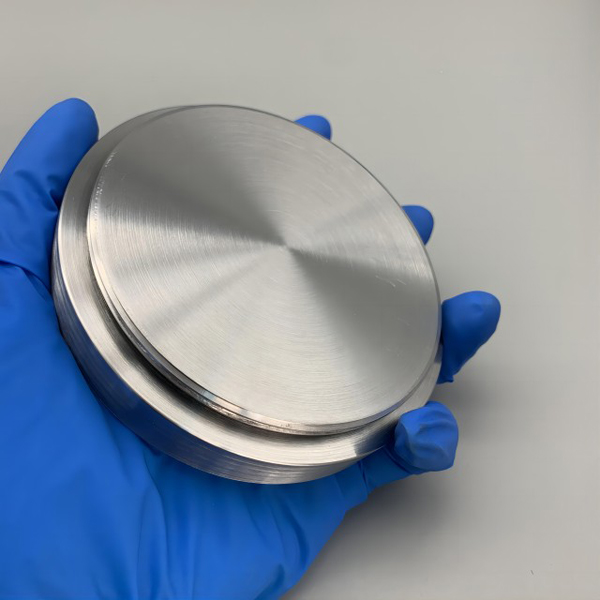

Titanium targets with a high melting point, good corrosion resistance, Ti metal target widely used in decoration and tool coating.

Iron target material is made of pure iron, which has high hardness and good magnetism. Fe has a melting point of 1538℃, Fe metal target is widely used in electronics, machinery and other fields, and can be deposited into films by a variety of sputtering processes.

Cobalt targets are mainly made of cobalt metal and have high melting point, strong magnetism and good wear resistance. It has applications in electronics, machinery, aerospace and other fields, and is used to prepare high-performance films.

Chromium target material is made of metal chromium as raw material. Chromium with hardness, wear resistance, corrosion resistance property , melting point of 1907℃, Cr target widely used in decoration, tool coating and optical coating and other fields.

Nickel target material with a hard, magnetic property used in microelectronics industry.

Gold sputtering target is made of high purity gold as raw material, Au sputtering target with chemical stability,Electrical conductivity and ductility. Au thin film coating materials are widely used in semiconductor, optical and Jewelry decoration, etc fields.

Tin target material is mainly composed of metallic tin. It has low melting point, soft texture and good ductility, and plays an important role in electronic welding, anti-corrosion coating and weldability coating.

Tungsten targets are made of tungsten metal. They possess high melting point, hardness and wear resistance, W magnetic sputtering target are widely used in electronics, coating and other fields.

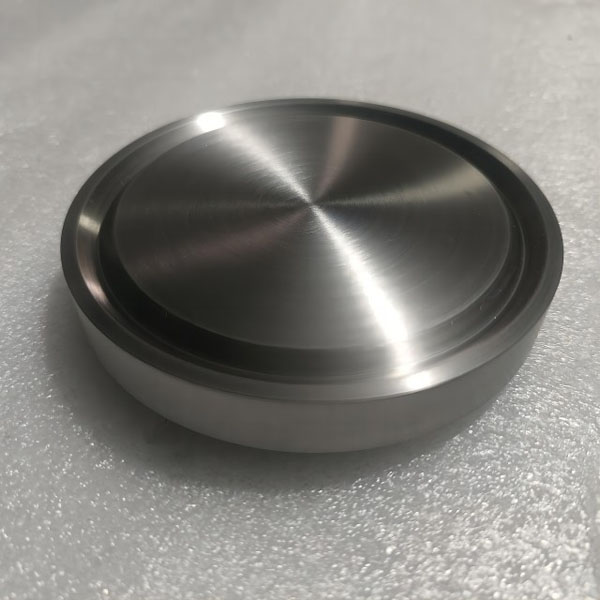

Tantalum targets are composed of tantalum. Ta targets with high melting point, excellent corrosion resistance and are vital for semiconductor and capacitor manufacturing.

Niobium targets are made of niobium metal. Nb pvd targets with high melting points and good conductivity, Nb sputtering target widely used in superconductors, electronics, and alloy coatings.

Vanadium targets are made of metallic vanadium. V sputtering target with a high melting point, great hardness and relatively stable chemical properties, and V metal materials are applied in steel metallurgy, electronics and aerospace etc. fields.

The bismuth target is mainly composed of bismuth. Bi target with low melting point,High specific gravity and other characteristics, Bi metal target has applications in semiconductor, electronics, medicine and other fields, and can be used to prepare a variety of functional films.

Iridium targets are made of the rare metal iridium and have extremely high melting point, hardness and chemical stability. Excellent performance in high-temperature environments, it is commonly used in the coating of engine components in the aerospace sector, as well as in the manufacture of high-precision electronic components in the electronics industry, which can significantly improve the wear and corrosion resistance of components, ensuring stable operation under extreme conditions

Carbon target are based on carbon elements, including graphite targets and other forms. It has good electrical conductivity and chemical inertness, and is used to prepare silicon carbide films in semiconductor manufacturing, which can improve the performance of electronic devices. In the field of optics, carbon films with special optical properties can be prepared and applied to lens coating to reduce reflection and improve light transmittance

Silicon target is one of the key materials in the semiconductor industry and usually has high purity. Its crystal structure is stable, which is widely used in the epitaxial growth of silicon wafers in integrated circuit manufacturing. Through physical vapor deposition and other technologies, the growth thickness and quality of silicon thin films can be accurately controlled, providing high-quality basic materials for chip manufacturing, and playing a key role in improving the performance of electronic devices.

Metal target purity 99.%-99.9999%, different purity, the application is different.

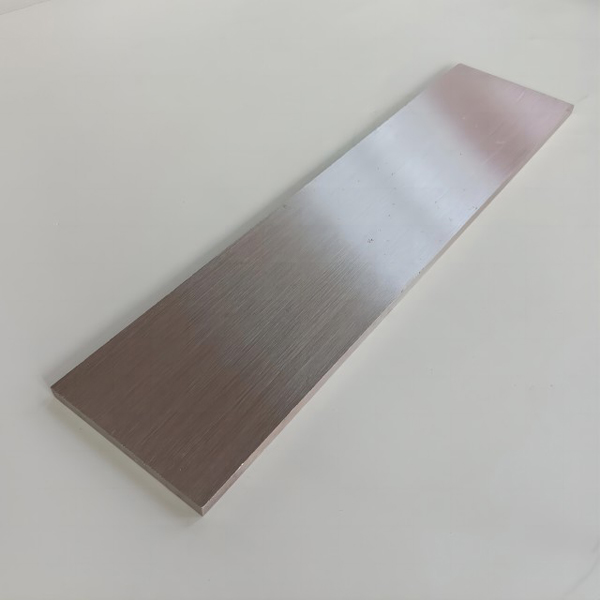

For some metal targets for general industrial use, the purity may be around 95% to 99%. For example, the metal targets used in some decorative coating fields have relatively low purity requirements, because they mainly use the appearance and basic physical properties of the metal, such as zinc targets partly used for hardware decoration, the purity may be about 98%.

In high-end areas such as the semiconductor industry, the purity of metal targets is extremely high, usually above 99.99% (4N), and even up to 99.9999% (6N). For example, in the manufacture of very large scale integrated circuit silicon target, its purity can be as high as 99.9999%, any small impurities can affect the performance and quality of the chip.

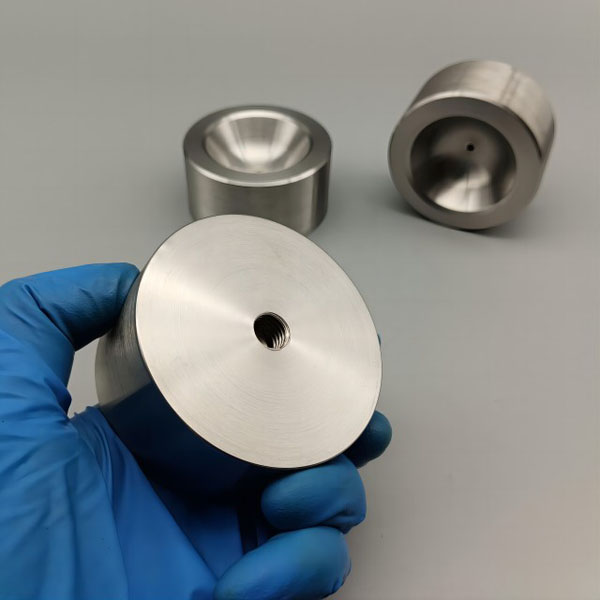

So metal target purity, size, shape need custom according to actual application and sputtering machine.

Post time: Dec-31-2024