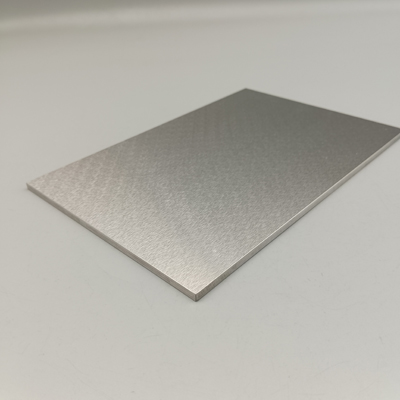

Iron-nickel alloys are a family of precision alloys primarily composed of iron and nickel (with nickel content typically ranging from 30% to 90%), whose properties are fine-tuned by adding small amounts of other elements (such as molybdenum, copper, chromium, etc.). They are not ordinary steels but a category of functional materials, renowned for their unique physical properties (like magnetic and thermal expansion characteristics)

Key Characteristics

The properties of iron-nickel alloys change significantly with varying nickel content. Their main features include:

1.Excellent Soft Magnetic Properties: In the high-nickel range (approx. 70%-80% Ni), the alloys exhibit extremely high magnetic permeability and very low coercivity, meaning they are easily magnetized and demagnetized with low hysteresis losses.

2.Special Thermal Expansion Properties: Around a specific nickel content (approx. 36%), the alloys possess an extremely low coefficient of thermal expansion (CTE) near room temperature, meaning their dimensions are nearly unaffected by temperature changes.

3.Tunable Elastic Properties: Some alloys have a constant modulus of elasticity or a low temperature coefficient of elasticity, meaning the stiffness of a spring made from them does not change with temperature.

Main Types and Representative Alloys

Based on their core properties, iron-nickel alloys are primarily classified into the following major categories:

| Category | Representative Alloy (Common Designation) | Typical Ni Content | Core Property | Main Applications |

|---|---|---|---|---|

| High-Permeability Soft Magnetic Alloys | Permalloy | 70%-80% | Extremely high initial and maximum magnetic permeability, low coercivity. | Cores for high-frequency transformers, instrument transformers, magnetic shielding, precision instruments. |

| Constant Permeability Alloys | Hard Permalloy / Isoperm | ~50% | Magnetic permeability remains essentially constant over a wide range of magnetic fields and temperatures. | Constant inductance components, unipolar pulse transformers. |

| Low Expansion Alloys | Invar (Alloy) | 36% | Extremely low coefficient of thermal expansion around room temperature (approx. -60°C to 100°C). | Structural components for precision instruments (e.g., watch balance springs, telescope mounts), laser cavities, microwave waveguides. |

| Sealing / Glass-Matching Alloys | Kovar (Alloy) | 29% | Coefficient of thermal expansion matches that of hard glass or ceramics, ensuring hermetic seals. | Lead wires, seals for vacuum electronic devices (e.g., microwave tubes, IC packages). |

| Constant Elasticity / Elinvar Alloys | Elinvar (Alloy) | ~36% (plus Cr, etc.) | Modulus of elasticity is almost unaffected by temperature changes. | Resonators for mechanical filters, precision springs, high-accuracy watch balance springs. |

Key Application Fields:

1.Electronics & Telecommunications: Used in inductors, transformers, magnetic heads, shielding cans, etc. They are core magnetic materials in high-end electronic equipment.

2.Precision Instrumentation & Measurement: Used to manufacture components requiring extreme dimensional stability, such as mounts for optical instruments, geodetic reference bars, sensor parts.

3.Aerospace & Aviation: Used in critical components of navigation devices like gyroscopes and accelerometers, as well as structural parts in satellites requiring thermal matching.

4.Vacuum Electronic Technology: Serves as a key material for glass-to-metal or ceramic-to-metal seals, widely used in vacuum tubes and semiconductor packaging.

5.High-End Consumer Goods: Balance springs in premium mechanical watches (Invar or Elinvar alloys), high-end magnetic heads in audio equipment, etc.

Production Process Characteristics

Iron-nickel alloys are precision alloys. Their production demands extremely strict control over composition, purity, hot working (rolling, forging), and final heat treatment processes (e.g., hydrogen annealing). Specific heat treatment regimes (like critical cooling) are crucial steps to achieve their superior magnetic or expansion properties.

Iron-nickel alloys are a type of “magical material” that maximizes the combination of iron and nickel through precise control of composition and processes. With controllable magnetic properties and thermal expansion characteristics as their core value, they play an irreplaceable and critical role in the “neural center” (electronic information) and “sensory system” (precision measurement) of modern technology, serving as a prime example of bridging fundamental materials science with high-end technological applications.

Post time: Dec-02-2025