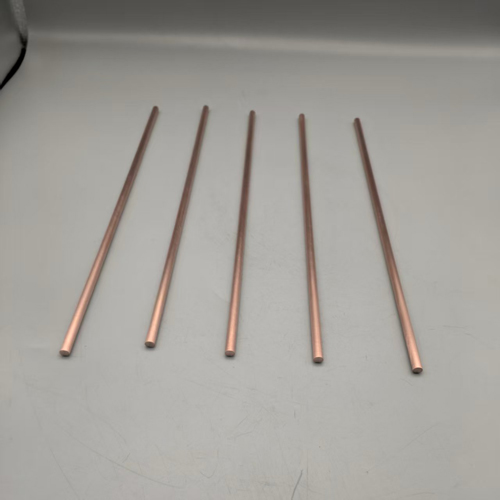

Here is a comprehensive introduction to copper-nickel alloy bars, covering their definition, common grades, core properties, main applications, and advantages.

1. What are Copper-Nickel Alloy Bars?

Copper-nickel alloy bars, commonly known as ”cupronickel bars,” are wrought products (bars) based on copper with nickel as the primary alloying element (typically ranging from 5% to 30% nickel, sometimes higher). They combine copper’s excellent thermal and electrical conductivity with nickel’s corrosion resistance and high strength, forming a class of superior engineering materials.

2. Common Grades and Compositions

The two most common industrial copper-nickel alloys are:

1.C70600 (or 90/10 Cupronickel): Composition: Approximately 90% copper, 10% nickel, with small additions of iron and manganese. Characteristics: Relatively low cost, it is the most widely used seawater corrosion-resistant alloy. It offers an excellent balance of corrosion resistance, workability, and strength.

2.C71500 (or 70/30 Cupronickel): Composition: Approximately 70% copper, 30% nickel, also containing small amounts of iron and manganese. Characteristics: Offers higher strength, better corrosion resistance (particularly against stress corrosion cracking), and superior high-temperature performance compared to the 90/10 alloy. It is also relatively more expensive.

3.Monel Alloy Series: Composition: Nickel (approx. 67%) is the primary element, with copper (approx. 30%) as the secondary, plus small amounts of iron, manganese, etc. Characteristics: Although often categorized as nickel-based alloys, their high nickel and copper content gives them properties far exceeding ordinary cupronickel, featuring very high strength, toughness, and exceptional resistance to acids, alkalis, and seawater corrosion. They are especially suited for extremely harsh environments.

3. Core Properties and Characteristics

- Excellent Corrosion Resistance:

- Resistance to Seawater Corrosion: The most outstanding advantage. A dense, stable protective film forms on the surface, providing high resistance to seawater, brine, brackish water, impingement, and cavitation erosion.

- Biofouling Resistance: Copper ions help inhibit the attachment of marine organisms (e.g., barnacles, algae).

- Resistance to Various Media: Good resistance to alkaline solutions, non-oxidizing acids, organic acids, and dry gases.

- Good Mechanical and Physical Properties:

- High Strength and Good Ductility: Strength is significantly higher than pure copper while maintaining good plasticity and toughness, allowing for easy hot and cold working.

- Resistance to Stress Corrosion Cracking: Performs better than many other copper alloys and some stainless steels in specific environments like those containing ammonia.

- Thermal and Electrical Conductivity: Although not as high as pure copper, it retains good thermal and electrical conductivity.

- Non-Magnetic: All copper-nickel alloys are non-magnetic.

- Good Fabrication Properties:

- Can be easily processed into bars and components of various sizes and shapes through drawing, forging, turning, milling, etc.

- Readily welded and brazed.

4. Primary Application Fields

Based on the above properties, copper-nickel alloy bars are widely used in:

- Shipbuilding and Marine Engineering: The most classic application.

- Components for seawater cooling systems, firefighting systems: fittings, valves, pump shafts, fasteners.

- Ship propeller shafts, rudder stocks.

- Desalination plant components, offshore platform structural parts.

- Power and Electronics Industry:

- High-performance connectors, resistors, relay components.

- Electrical equipment parts requiring non-magnetic and corrosion-resistant properties.

- Chemical, Petroleum, and Natural Gas Industries:

- Pumps, valves, agitator shafts for handling alkaline solutions, organic solvents, neutral and weakly acidic media.

- Components for piping systems in offshore oil and gas extraction.

- High-End Manufacturing:

- Corrosion-resistant precision mechanical parts, gears, bearing sleeves.

- Medical devices (e.g., surgical instrument components), musical instrument parts (e.g., flutes).

5. Summary and Advantage Comparison

| Property | Copper-Nickel Alloy Bar (e.g., 70/30) | Comparative Note |

|---|---|---|

| Seawater Corrosion Resistance | Excellent | Far superior to plain carbon steel and brass, comparable or superior to some stainless steels, with no risk of pitting. |

| Strength | Medium-High | Higher than pure copper and most brasses, lower than high-strength steels and Monel alloys. |

| Workability | Good | Easy to machine and form. |

| Cost | Relatively High | Higher than carbon steel and brass, but typically lower than premium corrosion-resistant materials like Monel or titanium alloys, offering good cost-performance. |

| Biofouling Resistance | Present | A unique advantage that reduces maintenance costs. |

In summary, copper-nickel alloy bars are a critical engineering material for demanding corrosive environments (especially marine applications). They occupy an irreplaceable position in industries such as shipbuilding, marine, and chemical processing due to their reliable performance, combination of excellent corrosion resistance, good mechanical properties, workability, and relatively reasonable cost.

Post time: Dec-09-2025