Chromium nickel sputtering targets, as high-performance materials, play a critical role in industries such as semiconductors, optical coatings, and new energy. However, many still have questions about their production process and application scenarios. This article delves into the core advantages, production methods, and market prospects of chromium nickel alloy targets, combining real-world cases and data to provide a comprehensive analysis.

What are Chromium Nickel Sputtering Targets?

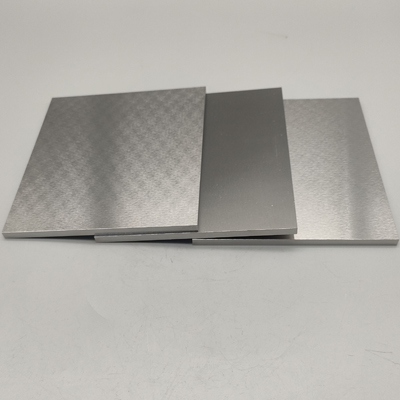

Chromium nickel sputtering targets are alloy materials composed of chromium (Cr) and nickel (Ni), primarily used in physical vapor deposition (PVD) processes. Their high purity, uniformity, and corrosion resistance make them an ideal choice for manufacturing thin-film materials.

Why Choose Chromium Nickel Alloy Targets?

1.High Corrosion Resistance: Maintains stable performance even in harsh environments.

2.Excellent Conductivity: Suitable for electronic component manufacturing.

3.High Hardness and Wear Resistance: Extends product lifespan.

Application Scenarios Semiconductor Industry:

Used in the production of integrated circuits and transistors.

Optical Coatings: Enhances the reflectivity of lenses and filters.

Solar Cells: Serves as electrode material, improving energy conversion efficiency.

Powder Metallurgy: The Core Production Process for Chromium Nickel Sputtering Targets

Powder metallurgy is the mainstream process for producing chromium nickel alloy targets. The specific steps are as follows:

1.Raw Material Preparation: Select high-purity chromium and nickel powders, mixing them in specific ratios.

2.Powder Mixing: Ensure uniform composition and avoid impurities.

3.Pressing: Compress the powder into pre-formed shapes under high pressure.

4.Sintering: Sinter in a high-temperature environment to form a dense alloy.

5.Post-Processing: Optimize performance through heat treatment and surface treatment.

Case Study: In a 2023 study by our team, we found that optimizing sintering temperature increased target density by 15%.

Chromium Nickel Sputtering Targets vs. Other Targets: A Comparative Analysis

| Item | Chromium Nickel Sputtering Targets | Pure Chromium Targets | Pure Nickel Targets |

|---|---|---|---|

| Corrosion Resistance | Extremely High | High | Moderate |

| Conductivity | Excellent | Good | Excellent |

| Cost | Moderate | Low | High |

| Application Range | Wide | Limited | Broad |

Future Trends of Chromium Nickel Sputtering Targets:

1.Technological Innovation: 3D printing technology is expected to enable customized target production.

2.Green Manufacturing: Reducing energy consumption and pollution during production.

3.Market Growth: According to Grand View Research, the global sputtering target market is projected to reach $7.6 billion by 2028, with an annual growth rate of 6.2%.

Chromium nickel sputtering targets, with their excellent performance and wide-ranging applications, have become indispensable materials in modern industry. Targets produced through powder metallurgy not only offer cost-effectiveness but also meet the demands of high-end applications. In the future, with continuous technological advancements, chromium nickel alloy targets will play an even greater role in more fields.

Post time: Jul-23-2025