In magnetron sputtering processes, the choice of target material is the first critical step determining thin-film performance. Engineers and procurement decision-makers often face a choice between two mainstream categories: high-purity metal targets and alloy targets. The core of the selection is not a simple matter of superiority or inferiority, but a deep understanding of their fundamental material differences and a precise match with your performance goals and application scenarios. This article will analyze their performance disparities, underlying mechanisms, and provide a clear selection logic.

1. Fundamental Differences: From “Single and Pure” to “Designed Fusion”

First, understand the basic distinction from a materials science perspective:

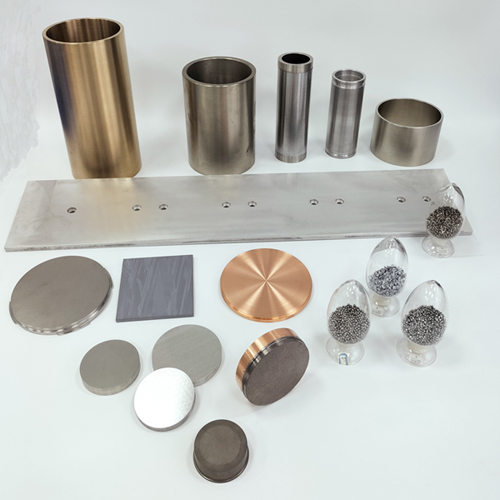

High-Purity Metal Targets: Typically consist of a single metallic element with extremely high purity (generally from 4N to 6N, i.e., 99.99% to 99.9999%). Their core value lies in the inherent intrinsic properties of the element, such as copper’s excellent conductivity, aluminum’s lightness and corrosion resistance, and tantalum’s chemical inertness.

Alloy Targets: Formed through metallurgical bonding of two or more metallic elements. Their core philosophy is ”performance design,” adjusting the elemental ratio to achieve comprehensive properties unattainable by a single metal, such as higher hardness, specific temperature coefficients of resistance, optimized optical constants, or stronger corrosion resistance.

2. Core Performance Comparison: In-Depth Analysis Across Five Dimensions

| Performance Dimension | High-Purity Metal Targets | Alloy Targets |

|---|---|---|

| 1. Film Composition & Purity | Film composition is pure and single, with extremely low impurity content, suitable for scenarios demanding the highest intrinsic material properties. | Film composition is essentially consistent with the target alloy composition, but slight deviations may occur due to differences in element sputtering rates, requiring process adjustments. |

| 2. Electrical & Optical Properties | Provide baseline performance. For example, pure silver has the lowest known bulk resistivity; pure aluminum’s reflectivity curve is an intrinsic property. | Provide tunable performance. For instance, adjusting the tin ratio in ITO (Indium Tin Oxide) optimizes the balance between conductivity and transparency in transparent conductive films. |

| 3. Mechanical & Structural Properties | Hardness is typically lower, with relatively fixed internal stress characteristics. Thin-film microstructure tends to form larger grains. | Area of significant advantage. Alloying can substantially increase film hardness, wear resistance, adjust internal stress (compressive or tensile), and refine grain structure. |

| 4. Chemical Stability | Depends on the metal’s own reactivity. For example, pure chromium has good passivation; pure copper oxidizes easily. | Area of significant advantage. Alloys with far superior corrosion and oxidation resistance compared to pure metals can be designed. For example, nickel-chromium alloy (NiCr) has much better high-temperature oxidation resistance than pure nickel or pure chromium. |

| 5. Process & Cost | Manufacturing processes are relatively mature, but controlling ultra-high purity (>6N) melting is difficult and costs surge. Sputtering process is stable with fewer arcs. | Manufacturing requires ensuring composition uniformity (control of macro-segregation), which is more challenging. Some alloy targets (e.g., high-entropy alloys) may have higher costs. |

Key Mechanism: The performance enhancement of alloy targets primarily stems from solid solution strengthening, second-phase strengthening, and the formation of dense passivation films (e.g., Cr2O3 in stainless steel). This gives them inherent advantages in mechanical and chemical durability.

Application Scenario Selection Guide: Matching Requirements is Key

Scenarios Best Suited for High-Purity Metal Targets

1.Semiconductor Interconnects & Wiring:

Applications: Copper interconnects (Cu), aluminum bonding pads in logic chips.

Reason: Pursuit of ultimate low resistivity (Rc) to reduce RC delay and power consumption; purity is paramount.

2. Superconducting & Quantum Devices:

Applications: Deposition of superconducting films like niobium (Nb), aluminum (Al).

Reason: Any trace magnetic or non-magnetic impurities severely affect the superconducting transition temperature (Tc) and coherence length.

3.Baseline Optical Films:

Applications: Pure aluminum (Al), pure silver (Ag) layers for mirrors.

Reason: Requires the material’s intrinsic optical constants (n, k) to reach theoretical optimum in specific wavelength bands.

Scenarios Best Suited for Alloy Targets

1.Resistive Films & Precision Resistors:

Applications: Thin-film resistors, strain gauges, thermistors. Commonly use nickel-chromium alloy (NiCr), chromium-silicon alloy (CrSi), tantalum nitride (TaN).

Reason: Require stable and tunable resistivity, low temperature coefficient of resistance (TCR), which pure metals cannot provide.

2.Hard, Wear-Resistant & Protective Coatings:

Applications: Cutting tool coatings (TiAlN), wear-resistant coatings for automotive engine parts, decorative coatings for mobile phone frames (Zr-based alloys).

Reason: Ultra-high hardness, high elastic modulus, and excellent wear resistance are core requirements.

3.Corrosion-Resistant & High-Temperature Oxidation-Resistant Layers:

Applications: MCrAlY coatings for aircraft engine blades, corrosion-resistant linings for chemical equipment, protection for devices in marine environments.

Reason: Rely on the dense, stable oxide films (e.g., Al2O3, Cr2O3) formed by the alloy for long-term protection.

4. Specific Functional Films:

Applications: Shape memory alloy films (NiTi), magnetic recording media (CoCrPt), semiconductor barrier layers (TiW).

Reason: The functionality arises directly from the alloy’s specific phase structure and electronic structure.

In the world of sputtering targets, high-purity metal targets are the “benchmark” and “pure pedigree” of performance, while alloy targets are the “designers” and “all-rounders” of functionality.

The wisest choice starts by stepping out of the “either-or” framework and returning to the core problem your final thin-film application needs to solve: Is it pursuing the ultimate flow of electrons, resisting harsh mechanical wear and chemical corrosion, or achieving a precise electro-thermal conversion function?

Understanding this fundamental difference will make your communication with target suppliers more targeted and enable you to evaluate technical solutions more effectively, thereby optimizing your process window and enhancing product competitiveness and yield.

Post time: Feb-02-2026