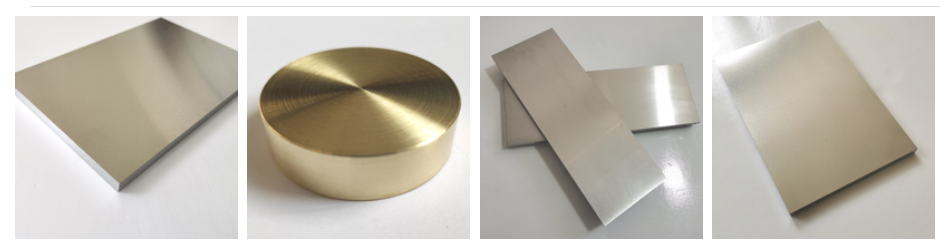

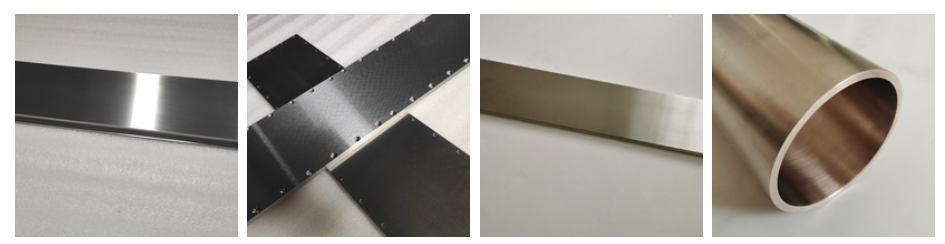

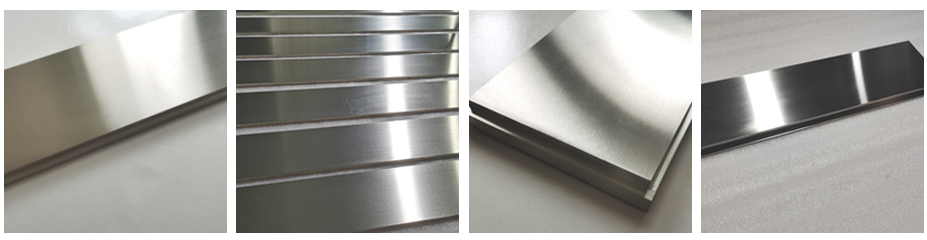

In today’s information age, semiconductor chips act as the “brains” of modern society, powering the operation of various electronic devices. Yet, in the intricate and complex process of chip manufacturing, a seemingly inconspicuous material plays a critical role—high-performance copper alloy sputtering targets.

1. Copper-Indium (Cu-In) Targets Characteristics: Good conductivity, plasticity, and compatibility with semiconductor materials. Applications: Primarily used in thin-film solar cells (e.g., CIGS thin-film solar cells) and optoelectronic materials.

2. Copper-Zinc (Cu-Zn) Targets Characteristics: Excellent corrosion resistance, machinability, and conductivity.Applications: Suitable for electronic components, decorative coatings, and corrosion-resistant layers.

3.Copper-Tin (Cu-Sn) Alloy Targets Characteristics: Good wear resistance, oxidation resistance, and conductivity. Applications: Used in electronic packaging materials, bearing coatings, and diffusion barrier layers in semiconductor devices.

4.Copper-Tungsten (Cu-W) Alloy Targets Characteristics: High melting point, high hardness, excellent thermal resistance, and conductivity. Applications: Suitable for high-power electronic devices, thermal management materials, and electrode materials in high-temperature environments.

5.Copper-Titanium (Cu-Ti) Alloy Targets Characteristics: High adhesion, oxidation resistance, and good conductivity. Applications: Mainly used for interconnect and barrier layers in semiconductor chip manufacturing.

6.Copper-Nickel (Cu-Ni) Alloy Targets Characteristics: Excellent corrosion resistance, thermal stability, and conductivity. Applications: Used in marine engineering, chemical equipment coatings, and conductive layers for electronic components.

7.Copper-Phosphorus (Cu-P) Alloy Targets Characteristics: Good deoxidizing properties, conductivity, and solderability. Applications: Used in electronic packaging materials, soldering materials, and electrode materials for semiconductor devices.

8.Copper-Aluminum (Cu-Al) Alloy Targets Characteristics: High hardness, good wear resistance, and oxidation resistance. Applications: Suitable for wear-resistant coatings, electronic components, and aerospace materials.

9.Copper-Chromium (Cu-Cr) Targets Characteristics: High hardness, excellent thermal resistance, and conductivity. Applications: Used in high-power electronic devices, electrode materials, and wear-resistant coatings for high-temperature environments.

10.Copper-Nickel-Manganese (Cu-Ni-Mn) Targets Characteristics: Good corrosion resistance, thermal stability, and conductivity.Applications: Suitable for precision resistor materials, electronic components, and conductive coatings in high-temperature environments.

11. Copper-Molybdenum (Cu-Mo) Targets Characteristics: High melting point, excellent thermal conductivity, and electrical conductivity. Applications: Primarily used in high-power electronic devices, thermal management materials, and electrode materials for high-temperature environments.

12.Copper-Manganese (Cu-Mn) Targets Characteristics: Good conductivity, plasticity, and oxidation resistance. Applications: Suitable for electronic components, resistor materials, and conductive layers in semiconductor devices.

13.Copper-Tantalum (Cu-Ta) Targets:Exceptional Electromigration Resistance and Thermal Stability: Suitable for chip manufacturing requiring high reliability and performance.

14.Copper-Magnesium (Cu-Mg) Targets:Superior Conductivity and Solderability: Perfect for power devices and RF (radio frequency) devices. The application of high-performance copper alloy targets provides a more reliable solution for semiconductor manufacturing, driving continuous advancements in chip technology.

Copper alloy targets are not only critical materials for semiconductor chip manufacturing but also play a vital role in numerous high-tech fields. From photoelectric conversion in solar cells to conductive coatings for electronic components, and from high-temperature protection in aerospace to wear-resistant surfaces.

Post time: Mar-15-2025