In the fields of advanced manufacturing and new material R&D, the demand for high-performance thin films is rapidly growing. Traditional single-metal targets, such as pure copper or chromium targets, are struggling to meet increasingly complex application scenarios. At this point, an innovative material solution has come into view—the Fe-Ti-Cu-Cr-Mn alloy target.

This multi-element composite target, through carefully designed elemental ratios, brings revolutionary performance improvements to magnetron sputtering processes. Today, let’s delve into its core advantages, application scenarios, and how to successfully master its use.

What is an Fe-Ti-Cu-Cr-Mn Alloy Target?

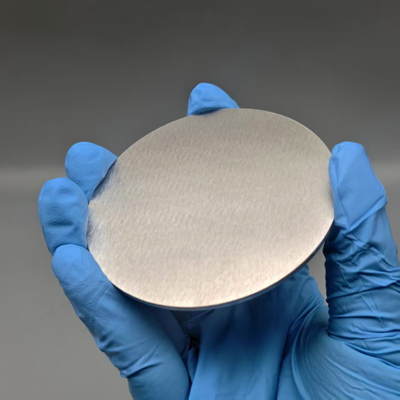

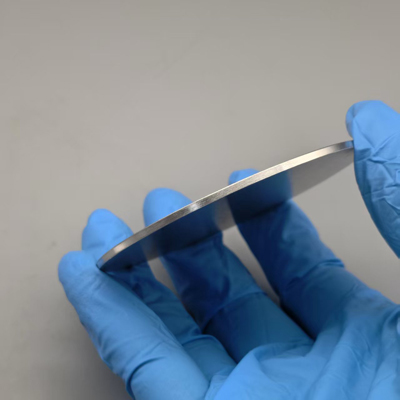

Simply put, the Fe-Ti-Cu-Cr-Mn alloy target is a sputtering target manufactured by melting and homogenizing five key metallic elements—iron (Fe), titanium (Ti), copper (Cu), chromium (Cr), and manganese (Mn)—using advanced metallurgical techniques. It falls under the category of high-entropy alloy targets. Its design philosophy leverages the “cocktail effect” of multiple principal elements to achieve comprehensive properties far exceeding those of traditional alloys.

Specifically, each element plays a unique role: iron and chromium provide excellent hardness and corrosion resistance; copper imparts good electrical and thermal conductivity; titanium refines grain structure and enhances adhesion; manganese further improves the alloy’s strength and wear resistance. Their synergistic effect results in a deposited film that combines high strength, low resistivity, strong adhesion, and exceptional stability. The Fe-Ti-Cu-Cr-Mn alloy target is an outstanding representative of this design concept.

Why Are Traditional Targets Challenged? How Does the Fe-Ti-Cu-Cr-Mn Alloy Target Provide a Solution?

Under harsh conditions, the weaknesses of many traditional thin films become apparent. For instance, pure silver films offer good conductivity but are highly susceptible to sulfidation and tarnishing; pure aluminum films are relatively soft and lack wear resistance. Excelling in one property often means compromising on others.

The Fe-Ti-Cu-Cr-Mn alloy target offers a “balanced and versatile” solution. Through elemental composition, it achieves “no compromise” across multiple key performance metrics. For example, the hardness of its deposited film can be more than three times higher than that of a pure copper film, while resistivity increases by only about 15%, achieving an excellent balance between strength and conductivity. This multi-element alloy target is becoming the key to solving complex engineering problems.

Core Performance Comparison: Traditional Targets vs. New Alloy Targets

To illustrate its advantages more intuitively, let’s compare them in the table below:

| Comparison Item | Traditional Single/Binary Alloy Targets (e.g., Copper Target, Chromium Target) | Fe-Ti-Cu-Cr-Mn Alloy Target |

|---|---|---|

| Film Hardness | Relatively low or high in one direction | Extremely high, with significant comprehensive strengthening effect |

| Resistivity | Either low or high, difficult to balance | Relatively low, good balance for conductivity needs |

| Wear/Corrosion Resistance | Usually focuses on one aspect | Excellent overall, synergistic protection |

| Film Stress | May be high, affecting adhesion | Better controllability, strong adhesion |

| Composition Uniformity | Relatively easy to control | Higher control requirements, but more uniform performance |

| Application Fields | Relatively singular | Broad, suitable for multi-functional scenarios |

However, it’s worth noting that high performance also means higher preparation thresholds and costs. The melting and processing technologies for Fe-Ti-Cu-Cr-Mn alloy targets are more complex, which is a factor users must weigh during selection.

Common Misconceptions and Pitfall Avoidance Guide

Several common pitfalls need to be vigilant about during application:

⚠ Warning: Do not treat the Fe-Ti-Cu-Cr-Mn alloy target as a “cure-all” by directly replacing the original target without adjusting the process. Its sputtering behavior and deposition characteristics are fundamentally different from single-metal targets. Comprehensive process re-development is essential; otherwise, film failure is highly likely.

⚠ Warning: Overly pursuing extreme content of a single element (e.g., arbitrarily increasing copper content for conductivity) may disrupt the overall phase structure and performance balance of the alloy, leading to increased film brittleness or degradation of other properties. The principle of synergistic optimization must be followed.

⚠ Warning: Neglecting the microstructural quality of the target. High-performance high-entropy alloy targets require extremely high compositional uniformity and density. Inferior targets can cause particle sputtering, film non-uniformity, and other issues, severely affecting product yield.

Future Outlook and Industry Impact

With the rapid development of 5G communication, high-end semiconductors, and the new energy industry, the requirements for thin film performance are approaching physical limits. According to the *2023 Global High-Entropy Alloy Market Report*, the market size for related targets is predicted to expand at a compound annual growth rate of 18.5% by 2028 [1]. Another study shows that protective coatings prepared using similar Fe-Ti-Cu-Cr-Mn alloy targets can increase the service life of precision components by an average of 2-5 times [2].

Interestingly, the impact of this material is not limited to performance enhancement. It drives magnetron sputtering technology toward more precise and controllable directions, while also catalyzing the development of a new generation of thin film deposition process monitoring technologies.

Counter-intuitively, although this five-element alloy target has a higher cost, the extended product lifespan, reduced maintenance costs, and performance improvements it brings often create greater economic benefits from a full life-cycle perspective.

Conclusion and Practical Checklist

In summary, the Fe-Ti-Cu-Cr-Mn alloy target represents an important trend in sputtering targets evolving from single-function to integrated and intelligent solutions. It is not a simple material replacement but a set of solutions that require systematic understanding and application.

Embracing material innovation is a key step toward high-end manufacturing. The Fe-Ti-Cu-Cr-Mn alloy target might just be the secret weapon for your next-generation product to achieve a performance leap.

Post time: Dec-11-2025