Basic introduce of Iron chromium aluminum alloy target :

Iron chromium aluminum alloy target is a kind of alloy material composed of iron, chromium and aluminum. Among them, iron is the base metal, chromium is the alloy strengthening element, and aluminum is the role of stabilization. Because of its high strength, high temperature stability, corrosion resistance and other excellent properties.

The characteristics of iron chromium aluminum alloy:

1.High strength: ferrochrome aluminum alloy has high strength, its strength is higher than ordinary steel, can meet a variety of high strength requirements of the engineering needs.

2. High temperature stability: ferrochrome aluminum alloy still has good strength and stability at high temperatures, and can be used for equipment and tools in high temperature environments.

3. Corrosion resistance: After the surface of ferrochrome aluminum alloy is treated, it can prevent fatigue, cracking and other problems caused by corrosion, which is suitable for Marine, chemical and other environments.

4. Good machinability: Fe-Cr aluminum alloy has good machinability and can be applied to casting, forging, plastic extrusion and other processes.

Application of iron chromium aluminum alloy:

Because of its excellent physical and chemical properties, FeCrAl alloy is widely used in aviation, aerospace, automotive, chemical and other fields. Its application scope includes several aspects:

1. Aviation and aerospace fields: Due to its high strength, high temperature stability, corrosion resistance and other characteristics, ferrochrome aluminum alloy is widely used in the aerospace field of manufacturing and maintenance.

2. Automotive field: Ferrochrome aluminum alloy is widely used in the manufacture of automotive engines, brakes, shells, chassis and other parts.

3.Chemical industry: ferrochrome aluminum alloy also has excellent corrosion resistance and can resist acid, alkali and other corrosion, so it is widely used in the manufacture of chemical equipment.

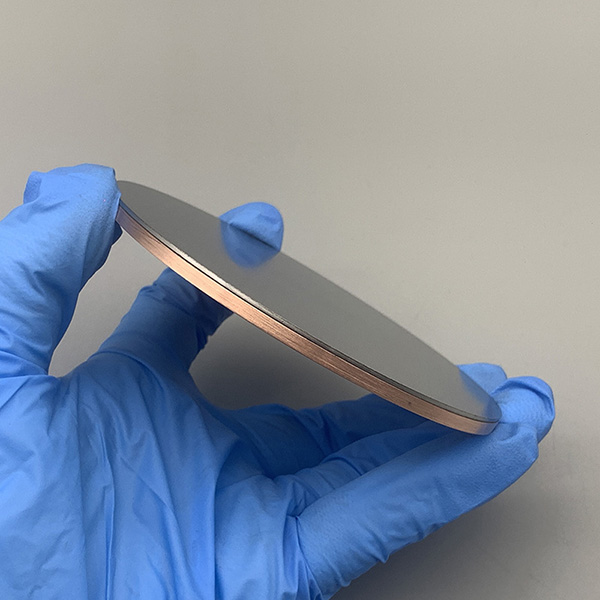

Why the sputtering target need binded a backplane?

1.Heat dissipation: During the sputtering process, the target will absorb a large amount of energy, resulting in an increase in temperature. Binding a backplane with high thermal conductivity (such as copper backplane) can effectively conduct the heat generated by the target, maintaining the stability of the target and uniform sputtering.

2.Mechanical support: The target is subjected to continuous physical impact during use, and binding to a sturdy backplane provides sufficient mechanical support to prevent the target from cracking or deformation.

3.Improved service life: Through the effective heat dissipation and mechanical support of the backplane, the loss and deformation of the target can be reduced, thereby extending the service life of the target.

4.Improved sputtering efficiency: The backplane can help the target receive the energy of the sputtering power source more evenly, achieving a more efficient and uniform film deposition.

how to bind a backplane?

1. Pretreat the target and backplane surface before binding

2. Place the target and the backplane on the brazing table and heat up to the binding temperature

3.Metalize the target and the backplane

4.Glue the target and the backplane

5.Cooling

Post time: Apr-10-2024