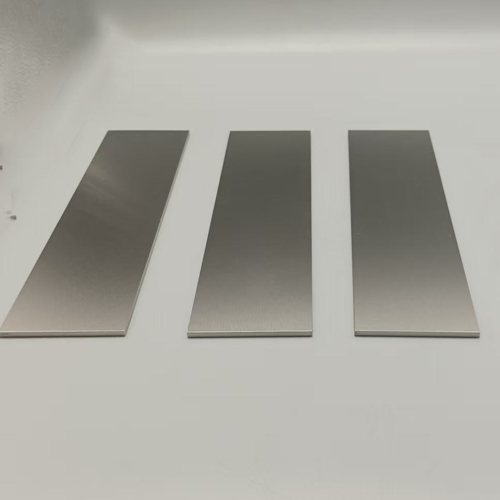

Sputtering targets are core materials in physical vapor deposition (PVD) technology, widely used in semiconductors, display panels, solar cells, and other fields. Metals such as iron (Fe), cobalt (Co), nickel (Ni), chromium (Cr), and aluminum (Al), along with their alloy targets, play a crucial role in high-performance thin-film fabrication due to their unique physical and chemical properties. This article explores the characteristics, applications, and future trends of Fe-Co-Ni-Cr-Al sputtering targets.

2. Material Properties

(1) Iron (Fe) Properties: High magnetic permeability, good ductility, tunable magnetic properties via doping. Target Applications: Magnetic thin films, sensors, data storage devices.

(2) Cobalt (Co) Properties: High Curie temperature, excellent magnetic anisotropy. Target Applications: Magnetic recording media, corrosion-resistant Co-based alloy coatings.

(3) Nickel (Ni) Properties: Corrosion-resistant, high catalytic activity, often alloyed with Fe/Co (e.g., permalloy). Target Applications: Electrode materials, electromagnetic shielding films.

(4) Chromium (Cr) Properties: High hardness, oxidation-resistant, forms dense passivation layers. Target Applications: Hard protective coatings, decorative plating.

(5) Aluminum (Al) Properties: Low density, high conductivity, readily forms protective Al₂O₃ oxide layer. Target Applications: Transparent conductive films (e.g., AZO), optoelectronic device electrodes.

Advantages of Alloy Targets Combining these metals (e.g., Fe-Co-Ni, Cr-Al) optimizes performance:

Magnetic Property Tuning: Fe-Co-Ni alloys for high-density magnetic storage.

Enhanced Corrosion Resistance: Cr-Al alloys improve high-temperature oxidation resistance.

Balanced Mechanical Properties: Ni-Cr alloys offer both strength and ductility.

Key Application Fields

1.Electronics Industry:

Conductive/barrier layers in semiconductor devices (e.g., Ni/Al).

Magnetic thin films for MRAM and hard disk drives (Fe-Co-Cr).

2.Optical Coatings:

3.Al targets for mirrors and Low-E glass.

Energy Sector:Electrode materials in solar cells (Cr/Al back-contact layers).

4.Protective Coatings:Cr-Al-Y alloy coatings for high-temperature corrosion resistance in aircraft engine blades.

Technical Challenges and Future Trends

(1) Challenges Purity Requirements: Semiconductor-grade targets demand purity above 99.999%. Uniformity Control: Grain refinement and compositional homogeneity in large-sized targets.

(2) Future Directions

High-Entropy Alloy Targets: e.g., FeCoNiCrAl, for multi-property synergy.

Nanostructured Targets: Improve thin-film density and adhesion.

Green Manufacturing: Reduce energy consumption and pollution during sputtering.

Fe-Co-Ni-Cr-Al sputtering targets, as the “source materials” for functional thin films, directly determine the reliability of end products. With the rapid growth of industries such as 5G and renewable energy, demand for targets will shift toward high-performance and customized solutions. Strengthening fundamental research (e.g., atomic-level interface design) and industry-academia collaboration is key to driving breakthroughs in this field.

Post time: Sep-29-2025