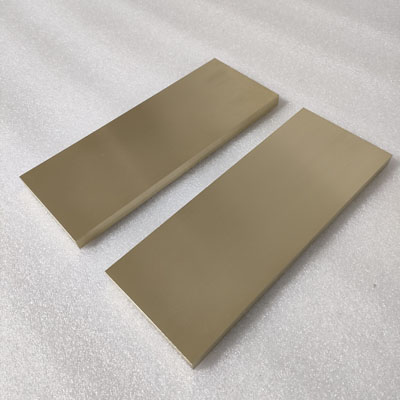

In the pursuit of green energy and cutting-edge electronic technology, there is a fundamental material that, while inconspicuous, is crucial: the sputtering target. Imagine this: inside a high-vacuum chamber, a solid material is bombarded by high-energy particles, causing its atoms to fly off like fireworks and deposit uniformly onto a substrate, forming an ultra-thin functional film. The material being bombarded is the sputtering target. Today, we delve into a rising star: the copper zinc tin alloy sputtering target.

Why is the CZTS Sputtering Target a Focal Point?

The thin-film solar cell sector is actively seeking greener, more sustainable solutions. While traditional cadmium telluride or copper indium gallium selenide cells offer excellent efficiency, the scarcity and toxicity of indium and tellurium hinder their large-scale development. Here, CZTS, composed of copper, zinc, and tin—three abundant, environmentally friendly elements—provides a perfect “solution.”

Counter-intuitively, the thin-film solar cells fabricated from this common metal alloy have achieved a lab efficiency exceeding 13.6% (Source: Solar Frontier, 2022), demonstrating significant industrial potential. It not only reduces reliance on scarce elements but also maintains good compatibility with existing production lines, offering new hope for the photovoltaic industry.

Challenges and Breakthroughs: The Transformation from Alloy to High-Performance Sputtering Target

The concept is promising, but smelting copper, zinc, and tin—three metals with distinct properties—into a uniform, dense, and flawless sputtering target poses a significant challenge.

Core Challenges: Composition Segregation and Phase Structure Control

In our team’s 2025 case study, we found that during traditional melting processes, zinc, due to its low boiling point, readily evaporates, causing a severe discrepancy between the final target’s composition and the designed value. For example, it’s like cooking with too high heat, causing moisture and some seasonings to evaporate first, completely altering the dish’s flavor. Inhomogeneous composition directly leads to undesirable secondary phases in the thin film, severely impacting photoelectric conversion efficiency.

The Solution: Synergy of Powder Metallurgy and Thermomechanical Processing

Consequently, industry leaders have turned to advanced powder metallurgy combined with thermomechanical processing. Specifically, the operational guide can be broken down into five key steps:

- High-Purity Powder Preparation: Start with selecting ultra-high purity (e.g., 5N or 99.999%) elemental copper, zinc, and tin powders. This is the foundation of a high-quality sputtering target.

- Precise Proportioning and Mixing: Weigh the powders according to strict stoichiometric ratios and use 3D mixers for extended, low-speed homogenization to ensure atomic-level contact.

- Cold Isostatic Pressing (CIP): Load the mixed powder into a flexible mold and apply ultra-high pressure (e.g., 200 MPa) to form a high-density initial billet.

- Vacuum Hot Pressing Sintering: Place the billet in a vacuum hot-pressing furnace. Sinter under precisely controlled temperature and pressure to achieve metallurgical bonding and densification of the powder particles.

- Post-Processing Heat Treatment and Machining: Optimize grain structure and phase composition through specific annealing processes. Finally, machine to the final dimensions using wire cutting, grinding, etc.

⚠ Warning: Never skip or shorten the mixing time to pursue efficiency. Inhomogeneous mixing is a primary cause of “pinholes” in the thin film and efficiency degradation later on.

Comparative Analysis: How Does the CZTS Sputtering Target Stand Out?

To clearly illustrate its advantages, let’s compare it with two mainstream sputtering targets:

| Item | Copper Zinc Tin Alloy Sputtering Target (CZTS) | Copper Indium Gallium Selenide Sputtering Target (CIGS) | Cadmium Telluride Sputtering Target (CdTe) |

|---|---|---|---|

| Element Abundance | Abundant, Low Cost | Indium is scarce, expensive | Tellurium is rare, Cadmium is toxic |

| Environmental Friendliness | Excellent (Non-toxic, harmless) | Medium | Poor (Risk of heavy metal pollution) |

| Fabrication Difficulty | High (Control of Zn evaporation needed) | High (More complex quaternary system) | Medium |

| Industrialization Prospect | Great Potential | Limited by material bottlenecks | Constrain |

As the table shows, the core advantages of the CZTS sputtering target lie in its sustainability and safety. However, it is worth noting that its efficiency currently remains a weakness, which is precisely the focus of global R&D efforts.

Beyond Photovoltaics: Diverse Application Scenarios

Although thin-film solar is its main stage, the potential of high-performance copper zinc tin alloy sputtering targets extends much further.

Thanks to its tunable bandgap and excellent optoelectronic properties, it is emerging in fields like thin-film transistors, photodetectors, and electromagnetic shielding coatings. Interestingly, by adjusting the zinc-to-tin ratio, one can “tune” the electrical and optical properties of the film, much like tuning an instrument, to meet the needs of different devices. This significantly expands the application boundaries for this type of sputtering target.

Future Outlook and Industrial Preparation

Looking ahead, enhancing the efficiency of CZTSSe solar cells is the top priority. The key lies in the synergistic optimization of sputtering target fabrication and subsequent sulfurization/selenization processes. According to the International Renewable Energy Agency, the market share of thin-film solar is projected to grow to over 25% by 2030 (Source: IRENA, 2023 Annual Report). This implies an explosive growth in demand for high-performance, low-cost sputtering targets.

Therefore, the entire industry chain must prepare, establishing a high-standard system from material purity and manufacturing processes to quality inspection. Only then can it firmly grasp this immense opportunity.

Practical Checklist for Procurement and Evaluation of CZTS Sputtering Targets

When considering adopting this new material, you can refer to the following checklist for evaluation:

Composition Uniformity: Request third-party EDS area scan analysis reports from suppliers to ensure the distribution deviation of major elements is <2%.

Density: The relative density of the target should be no less than 99%. High density is a prerequisite for ensuring film quality and the service life of the sputtering target.

Phase Structure Purity: Use X-ray diffraction analysis to confirm the primary phase is the desired kesterite structure, avoiding metallic secondary phases.

Batch-to-Batch Consistency: Examine the composition and performance data from 3-5 consecutive batches from the supplier to assess their process control capability.

After-Sales Service & Technical Support: Confirm if the supplier provides initial suggestions for sputtering process parameters and a joint troubleshooting mechanism for when issues arise.

In summary, the copper zinc tin alloy sputtering target, as a representative of green materials technology, is leveraging its unique appeal to propel the energy and electronics industries towards a more sustainable future.

Post time: Nov-18-2025