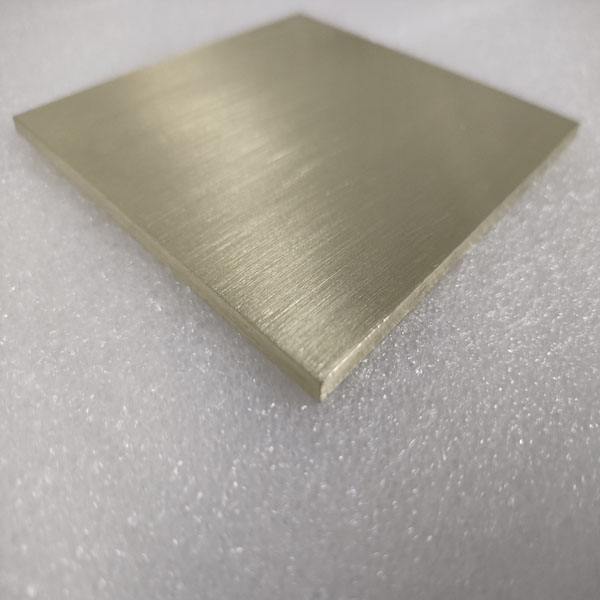

Copper-Zinc Alloy Sputtering Targets: Composition, Fabrication, and Applications

Copper-zinc alloy sputtering targets (Cu-Zn) are critical materials widely used in semiconductor manufacturing, photovoltaics, and optical coatings. Their performance advantages stem from the synergistic effects of copper and zinc, combined with high purity and precise microstructure control, enabling high-precision thin-film deposition. Below is an in-depth analysis of their composition, fabrication processes, applications, and market trends:

1. Composition and Key Properties

Core Composition:Copper content typically ranges between 60%-80%, with zinc at 20%-40%. Adjusting this ratio optimizes conductivity, corrosion resistance, and machinability. For example, Cu-Zn backplates (66-68wt% Cu, Zn balance) balance mechanical strength and solderability.

Impurity Control: High purity (e.g., 5N grade) is critical for film quality. Impurities like C <0.1% and Si <0.2% must be minimized to reduce film defects.

2. Fabrication Processes and Technical Challenges

Primary Fabrication Methods

Melting-Casting: High-temperature melting and casting ensure uniform microstructure but consume significant energy.

Powder Metallurgy: Pressing and sintering alloy powders achieve high density (>93% densification) but require precise control of powder size and sintering parameters.

Electroplating: Produces smooth surfaces for precision devices but suffers from low efficiency and high costs.

Key Technological Breakthroughs

Grain Refinement: Multi-stage hot forging (e.g., elongation-upsetting cycles) and segmented heat treatment (e.g., 300-500°C annealing) reduce grain size to <40μm.

Oxygen Control: Additives (e.g., in Ag-Cu-Zn targets) or vacuum melting lower oxygen content to <20ppm.

Applications and Case Studies

Semiconductor Manufacturing

Used in chip electrodes and lead frames, requiring high purity (5N grade) and uniform grains. For example, Jiangfeng Electronics supplies Cu-Zn targets for 7nm chip production lines.

Photovoltaics :Serve as conductive layers in CIGS (copper indium gallium selenide) thin-film solar cells. Target density (>93%) directly impacts film uniformity and energy conversion efficiency.

Optical and Display Devices:Applied in low-emissivity glass coatings as barrier layers to prevent silver oxidation while optimizing optical performance.

Catalysis and Environmental Protection:Act as catalyst supports for desulfurization and denitrification, leveraging high surface area and corrosion resistance.

Copper-zinc alloy plates, commonly known as brass plates, are composite materials primarily composed of copper and zinc. Their performance is significantly influenced by zinc content and additional elements such as nickel, manganese, and iron. Renowned for excellent electrical conductivity, thermal conductivity, corrosion resistance, and machinability, these materials are widely used in electronics, electrical engineering, plumbing, shipbuilding, and precision instruments.

Characteristics and Classification

Ordinary Brass (Binary Cu-Zn Alloy):Zinc content: 5%–45%.Single-phase α brass (Zn < 37%): Exhibits superior plasticity, ideal for cold working.Dual-phase α+β brass (Zn > 37%): Offers excellent high-temperature plasticity, requiring hot working.

Complex Brass (Special Alloys): Enhanced properties (corrosion resistance, strength, resistivity) through additions of nickel, manganese, or iron. Example: Zinc-nickel brass (BZn series)

Common Grades and Specifications

1. Ordinary Brass Series

H62 (CuZn38): 62% Cu, 38% Zn. Balances strength and plasticity; used in stamping parts, radiators, and architectural hardware.

H59 (CuZn41): Higher zinc content (~41%); requires hot working; common in mechanical parts and heat exchangers.

C26000 (UNS Standard): 70Cu-30Zn alloy with exceptional cold-working performance, suitable for surface-bonded laminates (SAE AMS4508 standard).

2. Complex Brass Series

BZn18-18: 18% Ni, 18% Zn. High corrosion resistance and precision machinability; used in instrument parts and decorative components.

BZn15-20: 15% Ni, 20% Zn. Ideal for high-strength, corrosion-prone environments (e.g., marine fittings).

3. International Standards

SAE AMS4508: 70Cu-30Zn laminate with surface-bonding technology, designed for aviation requiring high conductivity and mechanical strength.

STAS 289/2-1987: Romanian standard specifying brass plate dimensions (0.5–1mm thickness) for plastic deformation processing.

4. Other Grades

C26802: Dual-phase brass plate (~38% Zn), used in water tank strips and condenser tubes requiring cold/hot working.

C75700, C77010: Specialty alloys optimized for wear resistance or high-temperature strength via tailored compositions.

Rich special materials accept custom, Please provide the specifications of the materials you need, and we will promptly prepare a quotation for you.

Post time: May-13-2025