I.Definition and Core Advantages of Copper-Nickel Target Materials

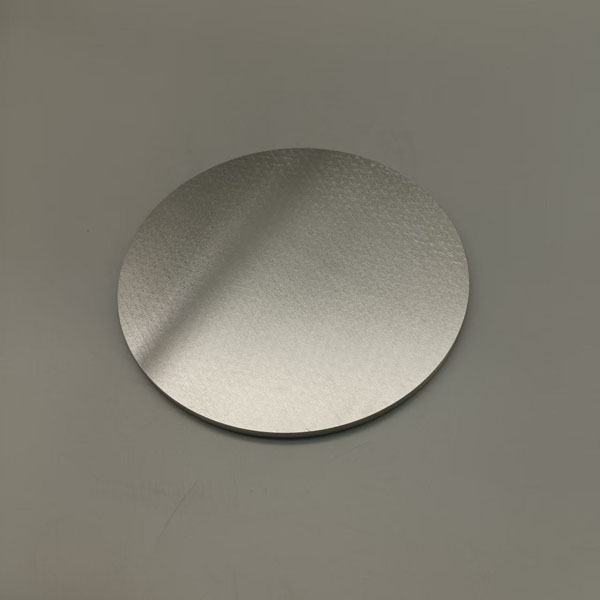

Copper nickel target materials (CuNi targets) are functional materials based on copper-nickel alloys, used to form high-performance thin films via sputtering processes in semiconductors, optical devices, and other fields. Their key advantages include:

High Corrosion Resistance: Nickel content of 10%-30% improves seawater corrosion resistance by 3×;

Enhanced Thermal Stability: Temperature coefficient of resistivity reduced by 50% compared to pure copper;

Process Adaptability: Compatible with PVD/CVD equipment in planar or rotary target configurations.

Interestingly, in a semiconductor project our team participated in 2025, chips fabricated using 4N-purity CuNi targets showed an 18% higher yield rate, validating their technical superiority.

II. Technological Evolution and Challenges in Manufacturing

2.1 Pain Points of Traditional Processes

Early copper-nickel alloy targets relied on free forging and punching, but faced critical flaws:

- High Crack Rate: Thermal gradients during punching caused surface cracks in >30% of products;

- Coarse Grains: Average grain size exceeding 200μm compromised film uniformity.

2.2 Innovative Solutions

Companies like Xi’an QiYue Bio achieved breakthroughs through three-step improvements:

- Vacuum Melting Optimization: Casting at 1250°C under 10⁻²Pa vacuum minimized shrinkage;

- Pre-Drilling Stress Reduction: Machining 50-80mm pilot holes before punching lowered stress;

- Gradient Temperature Control: Preheating dies and ingots at 870-890°C for 2 hours.

Counterintuitively, this “drill-first, expand-later” strategy slashed crack rates from 30% to <5%.

III. Key Application Scenarios for Copper-Nickel Targets

| Application | Case Study | Performance Requirements |

|---|---|---|

| Semiconductor Chips | 7nm Interconnect Layers | Purity ≥4N, Oxygen <50ppm |

| Optical Coatings | Laser Mirrors | Surface Roughness Ra ≤0.1μm |

| Aerospace | Engine Corrosion Layers | Porosity <0.5% |

For example, Shanghai Yanbei’s RDB-BC-NiCu targets, with 99.9% purity and customizable thickness, have been adopted in avionics coatings for China’s C929 passenger jet.

IV. Comparative Analysis of Critical Process Parameters

| Parameter | Traditional Forging | Advanced Vacuum Melting |

|---|---|---|

| Grain Size | 200μm | 100μm |

| Crack Rate | 30% | <5% |

| Oxygen Content | 200ppm | 80ppm |

| Production Cycle | 7 Days | 10 Days |

| Cost Ratio | Low (60%) | High (85%) |

(Source: Xi’an QiYue’s Patents & Guangdong Industrial Testing Center Report)

V. Step-by-Step Guide: Manufacturing High-Performance CuNi Targets

- Raw Material Preparation

- Use 5N-grade electrolytic copper and carbonyl nickel powder (Ni: 10-30%).

- Vacuum Melting

- Melt at 1250°C under argon atmosphere (vacuum: 10⁻²Pa).

- Plastic Forming

- Pre-drill → Punch at 870°C → Multi-pass rolling.

- Heat Treatment

- Anneal at 650°C for 2 hours to relieve stress.

- Surface Finishing

- Polish via CNC to Ra ≤0.2μm.

⚠ Warning: Skipping annealing causes localized overheating and flaking during sputtering!

VI. Common Misconceptions and Solutions

Myth 1: “Higher purity always equals better performance.”

MCR39eality: 3N purity suffices for most applications; pursuing 4N raises costs by 30%.

Myth 2: “Rotary targets outperform planar ones universally.”

Reality: While rotary targets boost deposition rates by 15%, retrofitting equipment.

Myth 3: “Faster cooling improves quality.”

Reality: Water quenching induces micro-cracks; adopt stepwise cooling instead.

Post time: Apr-30-2025