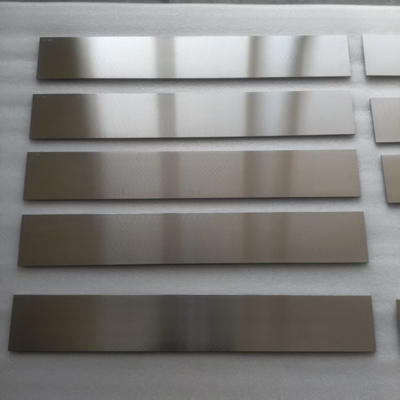

In the field of physical vapor deposition (PVD), nickel-based targets are indispensable key materials. Among them, pure nickel targets and nickel-chromium alloy targets occupy distinct application niches due to their unique properties. This article provides an in-depth comparison of the differences between the two and clarifies the basis for their selection.

I. Core Overview: Composition and Basic Properties

| Feature Dimension | Nickel Target | Nickel-Chromium Target |

|---|---|---|

| Primary Composition | High-purity nickel (≥99.9%) | Alloy of nickel and chromium; common ratios: 80Ni-20Cr, 60Ni-40Cr |

| Core Characteristics | Good ductility, ferromagnetism, electrical and thermal conductivity | Excellent high-temperature oxidation resistance and corrosion resistance |

| Mechanical Properties | Relatively soft, high toughness, easy to process and form | Higher strength and hardness, but increased brittleness, more difficult to process |

| Oxidation Resistance | Moderate, relies on surface NiO layer | Excellent, forms a dense and self-healing Cr₂O₃ protective film at high temperatures |

| Cost | Relatively low | Higher (due to strategic metal chromium content and complex processing) |

II. In-Depth Comparison of Properties and Coating Characteristics

1. Physical and Chemical Properties:

Nickel Targets are typical ductile metals with excellent processing properties. Their chemical stability is adequate, but in high-temperature, high-humidity, or specific corrosive media (e.g., sulfides), the protective nickel oxide film may fail, leading to corrosion.

The core performance of Nickel-Chromium Targets lies in the addition of chromium. Chromium preferentially oxidizes at high temperatures, forming an extremely stable and dense chromium oxide film, effectively blocking further ingress of oxygen and corrosive agents. This makes nickel-chromium alloy a classic high-temperature corrosion-resistant material. The trade-off is high alloy hardness and brittleness.

2. Sputtering and Coating Characteristics:

Nickel Coating: High deposition rate, dense and uniform film, easy to obtain low-resistivity pure metal films. The coating exhibits good adhesion and ductility.

Nickel-Chromium Alloy Coating:

Composition Control: Requires stable sputtering processes (e.g., using RF power or carefully controlled DC power) to ensure coating composition matches the target composition, avoiding deviation due to differences in elemental sputtering rates.

Functional Properties: The film not only inherits the excellent high-temperature oxidation and corrosion resistance of the bulk alloy but, more importantly, nickel-chromium alloy is the gold standard material for precision resistive thin films. By adjusting the Ni/Cr ratio, the film’s resistivity, Temperature Coefficient of Resistance (TCR), and long-term stability can be precisely controlled.

III. Divergence in Application Fields

The choice between the two is directly driven by their performance differences:

Primary Applications of Nickel Targets:

1.Conductive and Adhesion Layers: Used in microelectronic packaging, printed circuit boards, etc., as conductive connection layers or adhesion underlayers for metallization.

2.Electromagnetic Shielding Layers: Utilizes its good conductivity and magnetism to deposit electromagnetic interference shielding films in communication equipment and consumer electronics.

3.PVD Alternative for Electroplating Molds: Direct deposition of nickel films as final or intermediate layers on certain decorative or functional parts.

4.Battery Current Collector Coatings: Used to improve the conductivity and interface stability of electrodes in lithium-ion batteries.

Core Applications of Nickel-Chromium Targets:

1.Precision Resistive Thin Films (Dominant Application): In thin-film resistors, hybrid integrated circuits, and high-precision sensors, nickel-chromium alloy thin films are the material of choice for resistive elements. Their resistance values are stable, with low and controllable TCR.

2.High-Temperature Protective Coatings: Deposition of nickel-chromium-based coatings (e.g., MCrAlY coatings) on aircraft engine blades and hot-section components of gas turbines, providing crucial protection against high-temperature oxidation and hot corrosion.

3.Corrosion-Resistant Decorative and Functional Coatings: Used for high-end consumer goods like bathroom fittings and watches, providing unique colors (e.g., dark gray) and durable surfaces. Also used for corrosion-resistant coatings in chemical equipment and marine environments.

4.Thin-Film Thermocouples: Direct deposition of thin-film thermocouples in forms like nickel-chromium/nickel-silicon for real-time surface temperature measurement.

IV. Summary and Selection Guide

| Scenario | Prefer Nickel Target | Prefer Nickel-Chromium Target |

|---|---|---|

| Primary Need | High conductivity, good ductility, cost-sensitive conductive/adhesive layers | High-temperature stability, precise resistive properties, extreme environment corrosion resistance |

| Typical Application | Electronic interconnects, electromagnetic shielding, general-purpose plating | Thin-film resistors, protective coatings for high-temperature components, precision sensors |

| Process Consideration | Wide process window, easy deposition | Requires precise composition control, high demand for process stability |

Conclusion:

Nickel targets are the “versatile conductors” and “structural base materials,” focusing on providing reliable electrical connections, magnetic shielding, and mechanical support, offering good cost-effectiveness.

Nickel-chromium targets are the “functional specialists” and “protective guardians.” Their value lies in providing indispensable, stable resistive properties and exceptional ability to resist high-temperature oxidation and corrosion, making them key materials in high-end electronics and aerospace fields.

When selecting, the core functional requirement of the final film should be clarified first: Is it conductivity or resistance control? Is it ambient protection or high-temperature protection? The answer will clearly point towards either nickel or nickel-chromium.

Post time: Jan-12-2026