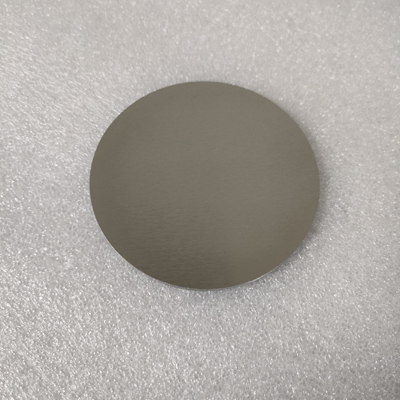

In the field of materials science, Cobalt-Chromium-Iron-Nickel (CoCrFeNi) alloy targets are rapidly emerging as a highly promising advanced material for preparing high-entropy alloy (HEA) thin films. With their unique compositional design and groundbreaking comprehensive properties, they offer innovative surface engineering solutions for numerous industrial sectors.

Core Composition and the “Cocktail Effect”

This target material is typically composed of four principal elements—cobalt (Co), chromium (Cr), iron (Fe), and nickel (Ni)—in equal or near-equal atomic ratios. It does not rely on a single principal element but leverages the synergistic “cocktail effect” of multiple core elements. This leads to the formation of a stable solid solution phase in its microstructure, which is the foundation of its exceptional performance.

Outstanding Comprehensive Performance AdvantagesExcellent Mechanical Properties: The resulting coatings simultaneously possess high strength, high hardness, and good toughness, effectively resisting deformation and crack propagation.

Superior Corrosion Resistance: The presence of chromium enables outstanding performance in oxidizing and corrosive environments, making it suitable for demanding working conditions.

Unique Functional Characteristics: Properties such as resistivity, magnetic performance, and high-temperature stability can be tailored through process adjustments, indicating broad application potential.

Diversified Frontier Application Fields

Protective Coatings for Extreme Environments: Applied to components like aerospace engine blades and gas turbine parts, providing protection against high temperatures, oxidation, and wear.

High-Performance Tool and Die Coatings: Significantly enhances the hardness, wear resistance, and service life of cutting tools and stamping dies.

Advanced Electronics and Functional Films: Serves as a novel functional material for researching resistors, magnetic layers, or diffusion barrier layers in fields like semiconductors and magnetic storage.

Surface Modification for Biomedical Devices: Its good corrosion resistance and biocompatibility make it a potential choice for surface enhancement of implantable devices.

As a professional supplier of Cobalt-Chromium-Iron-Nickel High-Entropy Alloy Sputtering Targets, we provide high-purity, compositionally uniform, and densified target products, along with customization services to meet your R&D and production needs.

Contact us today to obtain technical documentation and solutions for CoCrFeNi alloy targets, and let’s explore the future of high-performance coatings together!

Post time: Jan-19-2026