As the performance requirements for mechanical components in modern industry continuously increase, traditional coating materials are increasingly revealing their limitations. The chromium diboride sputtering target, as an emerging advanced coating material, is becoming a key solution to material protection challenges under extreme operating conditions, thanks to its exceptional hardness, corrosion resistance, and thermal stability.

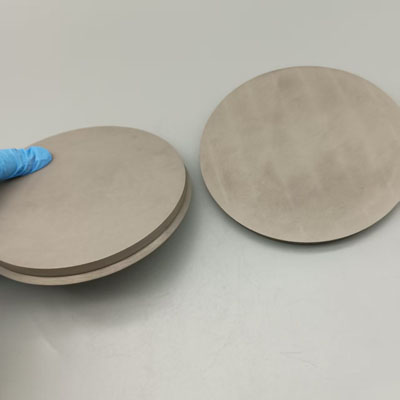

The chromium diboride sputtering target is a high-performance ceramic coating material offering extreme hardness, excellent corrosion resistance and thermal stability, widely used for surface protection in tool coatings, aerospace and semiconductor applications.

01 Industry Pain Points: The Limitations of Traditional Coating Materials

In many industrial fields, wear, corrosion, and high-temperature failure of mechanical components have long been persistent headaches for engineers. Traditional coating materials often excel in only one aspect, struggling to balance multiple performance requirements.

02 Characteristic Analysis: The Unique Advantages of Chromium Diboride Targets

The reason the chromium diboride sputtering target can become a rising star in solving industry pain points lies in its unique physical and chemical properties.

From a microstructural perspective, chromium diboride possesses an AlB2-type crystal structure, where boron and chromium atoms are stacked in a dense layered structure. This structure endows the material with excellent performance.

Specifically, the chromium diboride sputtering target has a melting point as high as 2200°C, a hardness r and simultaneously demonstrates outstanding performance in corrosion resistance and electrical conductivity.

Interestingly, by adjusting the deposition process, CrB2 coatings with different preferred orientations can be obtained. Coatings with a preferred orientation exhibit higher thermal stability, showing no significant phase transformation below 1000°C.

Performance Comparison: Chromium Diboride Sputtering Target vs. Traditional Coating Materials

| Performance Indicator | Chromium Diboride Sputtering Target | Traditional Titanium Nitride Coating | Traditional Tungsten Carbide Coating |

|---|---|---|---|

| Corrosion Resistance | Excellent | Medium | Medium |

| Electrical Conductivity | Good | Low | Low |

03 Technological Breakthrough: Innovations and Challenges in Preparation Processes

The preparation of the chromium diboride sputtering target is a highly technical process that directly impacts the performance of the final coating. Significant progress has been made in preparation technologies in recent years.

It is noteworthy, however, that the chromium diboride phase region is narrow, making it difficult to obtain a pure CrB2 phase at low temperatures. This necessitates precise control of process parameters during preparation.

⚠ Common Misconception Warning

1. Overemphasizing a Single Performance Indicator: During preparation, one cannot focus solely on hardness while neglecting toughness, otherwise the coating becomes prone to cracking.

2. Ignoring the Impact of Deposition Temperature: Deposition temperature significantly affects the coating structure and properties; temperatures above 300°C are required to obtain superhard CrB2 coatings.

3. Underestimating the Impact of Impurities: Insufficient raw material purity significantly reduces target performance; high-purity powder must be selected.

04 Application Scenarios: From Laboratory to Industrial Practice

The applications of the chromium diboride sputtering target are extensive, and its exceptional performance has been fully validated in practical applications.

In the field of wear-resistant protection, chromium diboride coatings are applied to cutting tools, molds, and key mechanical components, significantly extending their service life. One manufacturer reported a more than 3-fold increase in the service life of CrB2-coated cutting tools.

In the field of corrosion resistance, the self-corrosion current density of chromium diboride coating in a 3.5% NaCl solution is two orders of magnitude lower than that of the substrate material, making it promising for broad application in ships, offshore platforms, and chemical equipment.

In the field of high-temperature protection, chromium diboride coatings maintain good resistance to high-temperature , making them suitable for aero-engine components and high-temperature furnace elements.

The chromium diboride sputtering target also plays a role in the semiconductor industry, used for preparing thin films and protective coatings.

With the continuous emergence of new materials and processes, the application prospects of the chromium diboride sputtering target are even broader. In the future, we are likely to see more development of composite coatings and gradient coatings, as well as lower-temperature, more energy-efficient deposition processes.

Regardless of how technology evolves, the pursuit of high performance, long service life, and reliable protection will not change, and the chromium diboride sputtering target will undoubtedly continue to play a crucial role in this regard.

Post time: Nov-04-2025