The preparation process of sputtering targets directly affects their purity, density, microstructure, and final coating performance. The mainstream production methods currently include melting & casting, powder metallurgy, and spray forming, each with its own advantages and disadvantages, making them suitable for different material systems and application scenarios. Below is an in-depth analysis:

I. Melting & Casting 1. Process Principle High-purity metal raw materials (e.g., copper, aluminum, titanium) are melted in a vacuum or inert atmosphere and formed through casting, forging, or rolling, followed by machining to the required dimensions.

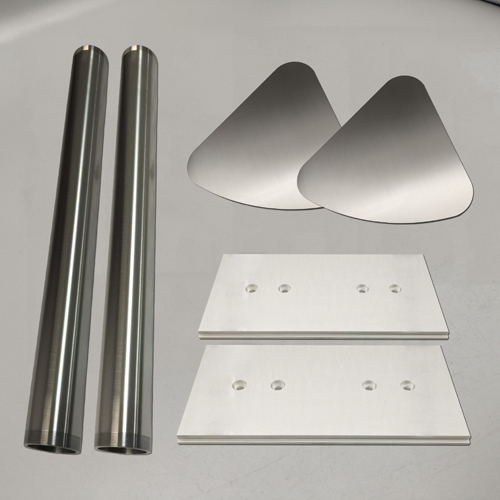

2. Core Process Flow High-purity raw material → Vacuum melting → Casting/Forging → Heat treatment → Machining → Backplate bonding → Finished product

3. Technical Advantages High purity: suitable for semiconductor-grade targets. High density: ≥99.5%, reducing particle sputtering during deposition. Grain control: Optimizes grain orientation through heat treatment (e.g., (111) orientation in copper targets).

4. Limitations Only applicable to meltable metals (refractory metals like tungsten and molybdenum require higher energy consumption). Large-sized targets are prone to composition segregation (e.g., dendrite formation in aluminum alloy targets). 5. Typical Applications Semiconductor copper interconnect targets (TSV, 3D NAND). Display panel aluminum/molybdenum electrode targets (TFT-LCD).

II. Powder Metallurgy

1. Process Principle High-purity metal or compound powders are formed through pressing, sintering (or hot isostatic pressing, HIP), suitable for refractory metals, ceramics, and composite targets.

2. Core Process Flow High-purity powder → Cold isostatic pressing (CIP) → Sintering/HIP → Machining → Backplate bonding → Finished product

3. Technical Advantages Wide material applicability: Can produce alloys, oxides, nitrides (e.g., ITO, TiN). Uniform composition: Avoids segregation issues in melting processes. Near-net shaping: Reduces material waste, suitable for complex-shaped targets.

4. Limitations Density is generally lower than melting methods (95%~99%), requiring HIP post-treatment. Oxygen content control in powders is challenging (e.g., titanium powder oxidation).

5. Typical Applications Transparent conductive targets (ITO, AZO). Hard coating targets (CrN, TiAlN).

III. Spray Forming

1. Process Principle Molten metal or alloy is atomized by high-speed gas and deposited onto a substrate, rapidly solidifying into shape. Suitable for high-entropy alloys, amorphous alloys, and other advanced targets.

2. Core Process Flow Molten metal → Atomization & spraying → Deposition forming → Heat treatment → Machining → Finished product

3. Technical Advantages Rapid solidification: Suppresses composition segregation and refines grains (nanocrystalline structure). High alloying capability: Suitable for multi-component materials (e.g., high-entropy alloy targets). Low oxidation risk: Conducted under inert gas protection.

4. Limitations High equipment costs, suitable for high-value-added targets. Higher porosity (requires subsequent HIP treatment).

5. Typical Applications High-entropy alloy targets (aero-engine coatings). Amorphous alloy targets (magnetic thin-film devices).

IV. Comparison of the Three Processes (Key Parameters)

| Process | Density | Purity | Cost | Applicable Materials |

|---|---|---|---|---|

| Melting & Casting | ≥99.5% | 3N~6N | Low~Medium | Cu, Al, Ti, meltable alloys |

| Powder Metallurgy | 95%~99% | 4N~5N | Medium~High | ITO, ceramics, refractory metals |

| Spray Forming | 90%~98% | 4N~5N | High | High-entropy alloys, amorphous materials |

The preparation processes of sputtering targets are primarily categorized into three major methods: melting & casting, powder metallurgy, and spray forming, each suitable for different material systems and application scenarios.

Melting & casting offers high purity and excellent density, making it the mainstream process for semiconductor-grade metal targets. Powder metallurgy provides uniform composition and broad applicability, particularly suited for ceramics and composite materials. Spray forming enables rapid solidification and high alloying capability, demonstrating advantages in novel targets like high-entropy alloys.

Looking ahead, the development of target preparation technology will focus on optimizing hybrid processes, green manufacturing, and intelligent control.

Post time: Sep-30-2025