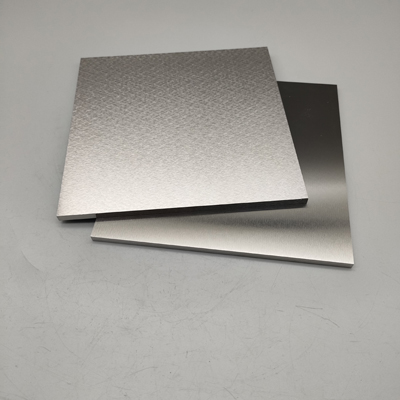

In today’s rapidly advancing fields of advanced manufacturing and materials science, sputtering targets, as core materials for surface engineering and thin-film preparation, are playing an increasingly vital role.

Among them, nickel-cobalt-iron-aluminum-chromium-titanium (Ni-Co-Fe-Al-Cr-Ti) alloy sputtering targets have gained widespread application in high-tech industries such as semiconductors, aerospace, and new energy due to their diversified compositional design and excellent comprehensive properties.

01 Product Composition Introduction

Nickel-cobalt-iron-aluminum-chromium-titanium alloy sputtering targets are multi-component composite metal materials with intricate compositional designs, where each element synergistically contributes to the target’s outstanding overall performance.

These alloy targets typically consist of major elements such as nickel (Ni), cobalt (Co), iron (Fe), aluminum (Al), chromium (Cr), and titanium (Ti), with their proportions adjusted according to application requirements.

Each element plays a distinct role in the alloy:

Nickel (Ni): As the matrix element, nickel provides excellent high-temperature stability and corrosion resistance, forming the fundamental framework of the alloy.

Cobalt (Co): Cobalt significantly enhances solid solution strengthening effects, improves high-temperature creep resistance, and contributes to the long-term stability of the microstructure.

Chromium (Cr): Chromium is a key element for oxidation and corrosion resistance, forming a dense chromium oxide (Cr₂O₃) protective layer on the material’s surface at high temperatures.

Aluminum (Al) and Titanium (Ti): These two elements are critical for forming the γ’ strengthening phase, combining with nickel to create Ni₃(Al,Ti) precipitates, which greatly enhance the alloy’s strength.

Iron (Fe): Iron serves as both a matrix element and a modifier for magnetic and mechanical properties, while also helping to control costs.

02 Material Property Analysis

Nickel-cobalt-iron-aluminum-chromium-titanium alloy sputtering targets exhibit a combination of exceptional properties, ensuring stable performance under demanding conditions.

High-Temperature Strength and Creep Resistance

One of the standout features of these alloy targets is their superior high-temperature strength and creep resistance. The material maintains high strength and resists slow plastic deformation (creep) even under prolonged high-temperature conditions.

Oxidation and Corrosion Resistance

Thanks to their relatively high chromium content (typically 9%–16%), these alloy targets form a dense, adherent chromium oxide (Cr₂O₃) protective layer at high temperatures, effectively resisting oxidation and various forms of thermal corrosion. The presence of aluminum further stabilizes this protective layer under extreme conditions.

Microstructural Stability and Mechanical Properties

During long-term high-temperature exposure, nickel-cobalt-iron-aluminum-chromium-titanium alloy targets maintain relatively stable microstructures, with minimal coarsening of the γ’ phase, ensuring long-term reliability. Additionally, these targets exhibit high room-temperature strength, enhancing their durability during processing and use.

Tunable Magnetic and Physical Properties

By adjusting the ratios of nickel, cobalt, and iron, the magnetic properties of the alloy targets can be precisely tailored to meet the requirements of different applications. This flexibility allows them to be used in both magnetic thin-film preparation and non-magnetic environments, broadening their application scope.

03. Production Processes and Manufacturing Methods

The production of nickel-cobalt-iron-aluminum-chromium-titanium alloy sputtering targets involves complex and precisely controlled processes, including the following key steps:

1.Raw Material Preparation

2.Mixing and Compaction

3.Sintering and Densification

4.Heat Treatment Optimization

5.Machining and Quality Inspection

04. Application Fields

Thanks to their superior performance, nickel-cobalt-iron-aluminum-chromium-titanium alloy sputtering targets play an irreplaceable role in numerous high-tech industries:

Semiconductor Industry

In semiconductor manufacturing, these alloy targets are used for sputter deposition to form conductive layers, diffusion barriers, or magnetic thin films. These layers serve critical functions in integrated circuits, such as interconnects, diffusion prevention, and data storage.

Flat-Panel Displays and Glass Coatings

In liquid crystal displays (LCDs) and architectural glass coatings, these alloy targets are employed to produce low-emissivity coatings, transparent conductive films, and electrochromic thin films.

Aerospace and Gas Turbines

In this sector, nickel-cobalt-iron-aluminum-chromium-titanium alloy targets are primarily used to fabricate high-temperature protective coatings, safeguarding critical hot-section components from oxidation and corrosion. Specific applications include:

Turbine blades and guide vanes

Combustor components such as flame tubes and cross-fire tubes

High-temperature fasteners and other parts exposed to extreme conditions

These coatings significantly extend component service life and operational temperatures, improving engine efficiency and reliability.

Tool and Mold Coatings

Coatings produced using these alloy targets enhance the hardness, wear resistance, and high-temperature oxidation resistance of cutting tools and forming molds.

New Energy and Environmental Protection

In solar cells, fuel cells, and energy storage systems, these alloy targets are used to prepare functional thin films, such as electrode materials, catalytic layers, and protective coatings, improving energy conversion efficiency and device longevity.

Precision Optics and Decorative Coatings

In optical components and high-end decorative applications, these alloy targets are utilized to produce high-reflectivity films, wear-resistant protective coatings, and decorative finishes, combining aesthetic appeal with superior physical properties.

Through precise compositional adjustments and sophisticated manufacturing processes, these multi-principal element alloy targets achieve optimized and upgraded material performance, making them indispensable key materials in modern industry.

Post time: Oct-27-2025