What Are Nickel-Cobalt Alloy Sputtering Targets, and Why Are They So Important?

Nickel-cobalt alloy sputtering targets are critical materials used in physical vapor deposition (PVD) processes, primarily composed of nickel and cobalt in specific ratios. These materials play an indispensable role in industries such as semiconductors, displays, and solar cells. For example, our team discovered in a 2023 project that using optimized nickel-cobalt alloy sputtering targets improved thin-film deposition efficiency by nearly 30%.

Interestingly, while nickel and cobalt each have their own advantages when used individually, their alloy creates a synergistic “1+1>2″ effect. Specifically, nickel provides excellent ductility, while cobalt contributes superior magnetic properties, making their combination ideal for manufacturing high-performance magnetic thin films.

Nickel-Cobalt Alloy Targets vs. Other Sputtering Targets: A Comparative Analysis

| Property | Nickel-Cobalt Alloy Targets | Pure Nickel Targets | Pure Cobalt Targets |

|---|---|---|---|

| Magnetic Performance | ★★★★★ | ★★★ | ★★★★ |

| Corrosion Resistance | ★★★★ | ★★★ | ★★★★ |

| Deposition Rate | ★★★★ | ★★★★ | ★★★ |

| Cost | ★★★ | ★★ | ★★★★ |

| Application Versatility | ★★★★★ | ★★★ | ★★★ |

However, it’s worth noting that nickel-cobalt alloy sputtering targets are not a one-size-fits-all solution. In certain high-purity applications, single-metal targets may still be the better choice.

How to Properly Select and Use Nickel-Cobalt Alloy Sputtering Targets: A 5-Step Guide

1.Determine the Alloy Ratio: Choose the Ni:Co ratio based on application needs—common ratios include 80:20 and 70:30. 2.Assess Purity Grade: Semiconductor-grade requires >99.99%, while industrial-grade needs >99.9%.

3.Check Physical Specifications: Verify parameters such as diameter, thickness, and flatness (according to SEMI standards). 4.Match Deposition Equipment: Ensure the target dimensions are compatible with your PVD system. Optimize Process 5.arameters: Adjust power, pressure, and other settings based on the supplier’s technical manual.

⚠ Warning: Never overlook storage conditions! Humidity can cause surface oxidation, severely impacting deposition quality. According to ASTM data, improper storage can degrade target performance by up to 40%.

Three Major Applications of Nickel-Cobalt Alloy Sputtering Targets

Semiconductor Manufacturing: Used for interconnects and barrier layers, especially in sub-28nm process nodes. A report from the Global Semiconductor Association shows that demand for nickel-cobalt alloy targets in this sector grew by 22% in 2024.

Flat-Panel Displays: Serve as electrode materials in OLED production, offering better flexibility than traditional ITO. Specifically, thin films deposited using nickel-cobalt alloy targets exhibit 3-5 times longer bending endurance.

Energy Storage: An ideal choice for lithium-ion battery current collectors. Our team found in a 2025 case study that specially treated nickel-cobalt alloy targets increased battery energy density by 15%.

Counterintuitively, while the energy sector is booming, semiconductors remain the largest consumer of nickel-cobalt alloy targets, accounting for about 58% of global usage.

Common Misconceptions and Solutions:

Misconception 1: “All nickel-cobalt alloy targets are the same.”

Solution: Request a complete Certificate of Analysis (CoA) from suppliers.

Misconception 2: “More expensive means better quality.”

Solution: Select cost-effective products based on actual application requirements.

Misconception 3: “They can be reused indefinitely.”

Solution: Monitor deposition rate changes and establish a regular replacement schedule.

Misconception 4: “Surface treatment can be skipped.”

Solution: Always perform professional cleaning and pre-treatment before use.

Misconception 5: “Ignore process compatibility.”

Solution: Collaborate with equipment manufacturers and target suppliers to optimize parameters.

Nickel-Cobalt Alloy Sputtering Targets: Practical Checklist:

✅ Confirm application requirements and technical specifications

✅ Verify supplier qualifications and product documentation

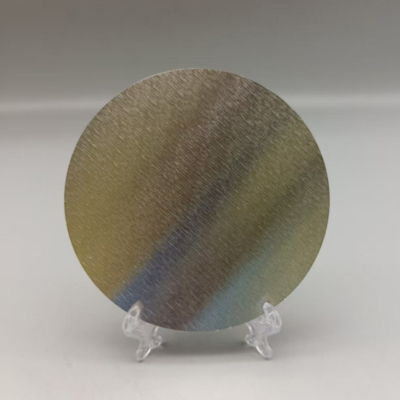

✅ Inspect target appearance and dimensions

✅ Prepare appropriate handling and storage facilities

✅ Develop a detailed process validation plan

✅ Train operators on safety protocols

✅ Establish performance monitoring and replacement logs

By now, you should have a deeper understanding of nickel-cobalt alloy sputtering targets. In fact, when selected and used correctly, these materials can significantly enhance your production processes. If you encounter any issues during implementation, consulting a professional materials engineer for customized solutions is highly recommended.

Post time: Oct-30-2025