42CrMo alloy steel is a high-performance material widely used in industrial fields, renowned for its excellent strength, toughness, and wear resistance. This article delves into the composition, properties, applications, and international significance of 42CrMo, providing a comprehensive understanding of this material.

Composition and Properties of 42CrMo Alloy Steel

42CrMo is a medium-carbon alloy steel with the following chemical composition:

Carbon (C): 0.38-0.45% – Provides high hardness and strength.

Chromium (Cr): 0.90-1.20% – Enhances wear and corrosion resistance.

Molybdenum (Mo): 0.15-0.30% – Improves high-temperature strength and hardenability.

Manganese (Mn): 0.60-0.90% – Enhances toughness and machinability.

Silicon (Si): 0.15-0.40% – Strengthens the material structure.

42CrMo alloy steel key Properties:

1.High Strength: 42CrMo exhibits exceptional yield and tensile strength, making it suitable for high-load environments.

2.Good Toughness: Maintains excellent impact resistance even at low temperatures.

3.Wear Resistance: High surface hardness makes it ideal for wear-resistant components.

4.Heat Treatment Performance: Can be further enhanced through quenching and tempering processes.

International Standards and Naming of 42CrMo

In the global market, 42CrMo is commonly referred to as 42CrMo4, with standards including:

EN Standard: 42CrMo4 (European Standard).

DIN Standard: 42CrMo4 (German Standard).

ASTM Standard: 4140/4142 (U.S. Standard, with similar composition).

ASTM Standard: 4140/4142 (U.S. Standard, with similar composition).

This unified naming system makes 42CrMo easily recognizable and applicable worldwide.

Applications of 42CrMo

Thanks to its exceptional properties, 42CrMo is widely used in the following fields:

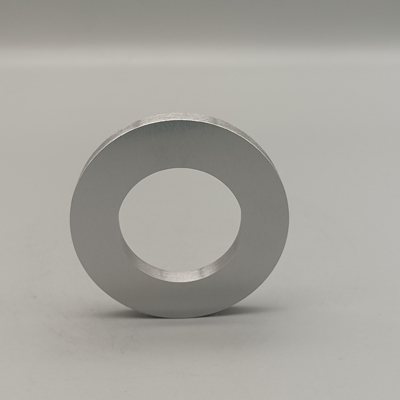

- Mechanical Manufacturing: Used in high-strength components such as gears, shafts, and connecting rods.

2.Automotive Industry: Applied in critical parts like transmission components and engine parts.

3.Oil and Gas: Used in drilling equipment, high-pressure pipelines, and other high-pressure, corrosion-resistant environments.

4.Mold Manufacturing: Suitable for high-load molds, extending service life.

5.Aerospace: Ued in aircraft landing gear, engine components, and other high-performance parts.

42CrMo alloy steel (internationally ksnown as 42CrMo4) is a high-performance material that plays a vital role in mechanical manufacturing, automotive industry, oil and gas, and more, thanks to its high strength, toughness, and wear resistance. Understanding its composition, properties, and applications .

Post time: Jul-04-2025